Motor stator winding machines are mainly categorized into internal and external winding machines, which are distinguished according to the direction of the slots of the stator. The internal winding machine is mainly for stator products with inward slots, such as power tool motors, household electrical appliances motors, medical equipment motors and so on. External winding machines are mainly for stator products with slots facing outward, such as aeromodelling motors, drone motors, twisted car motors and so on.

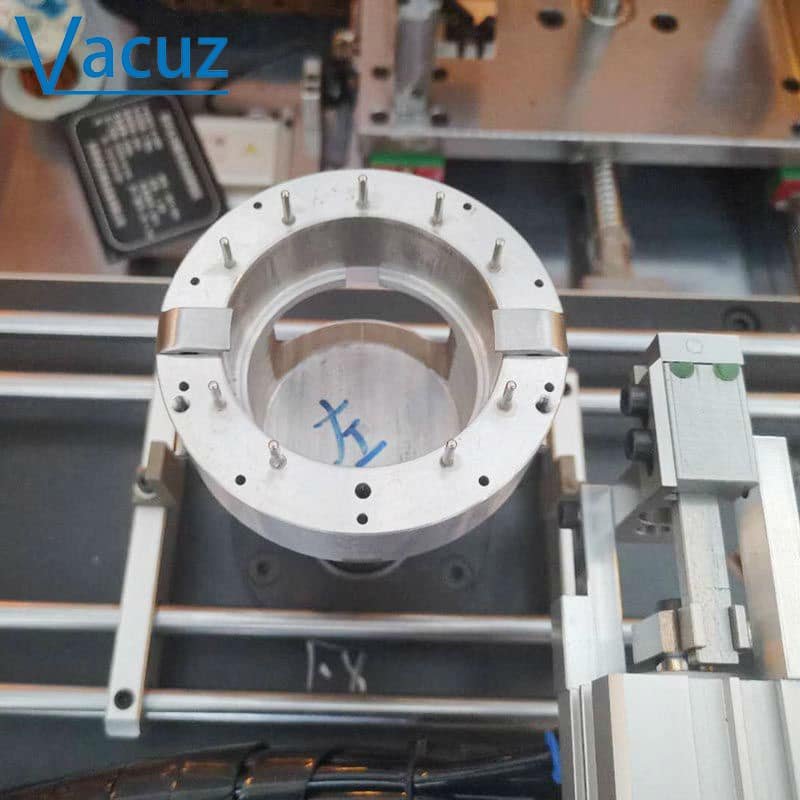

The inner winding machine requires higher precision and is relatively expensive. It adopts the needle winding method, carrying the enameled wire through the nozzle of the needle bar, which can be moved up and down or left and right, and cooperate with the mold and the wire arranging mechanism, so as to wind the wire neatly and neatly onto the stator. The outer winding machine, on the other hand, adopts the flying fork winding method, in which the flying fork wire nozzle carries the enameled wire, rotates at high speed, and through the interplay of die head, mold, and guard plate, it makes the wire wind into the stator groove in a circle one after another.

When selecting a motor stator winding machine, you need to choose the right model and configuration according to your actual needs and budget. For internal winding machines, you need to pay attention to its precision, configuration needs and price. For the external winding machine, you need to pay attention to its winding method, speed and price.

The use of motor stator winding machine need to pay attention to some details. First of all, the tension control should be reasonable, the tension should be uniform, not too big or too small. If it is too large, it is easy to break the wire, hurt the wire, resulting in defective products; if it is too small, the coil winding is loose, not compact, affecting the slot full rate. Secondly, the winding parameters should be set correctly, generally speaking, different models of products have a special winding program, do not need to modify, provided by the manufacturer can be directly imported. In addition, the winding speed can not be too fast, especially when the start winding needs to be slow winding, to ensure that the machine is stable before increasing the speed. Again, if the machine malfunctions need to stop in time to investigate the cause of the problem before continuing to use.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]