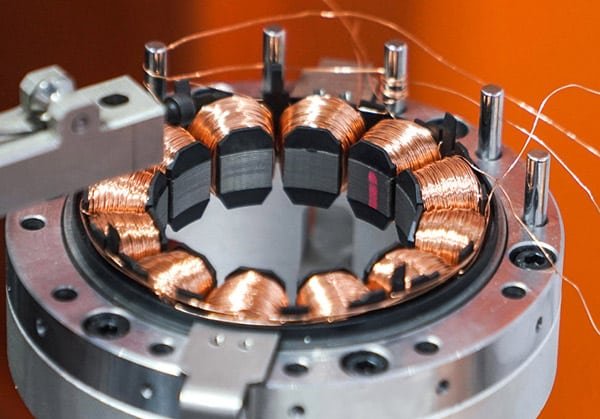

Brushless motor stator coil winding machine is mainly used to wind stator products, different winding machine equipment, precision and configuration requirements are different, for the winding quality requirements are also different, then the precision of the brushless winding machine on the winding quality and efficiency have an impact? Vacuz give you an introduction to it!

First, the significant impact on the quality of winding

1. Dimensional accuracy: the dimensional accuracy of the winding machine is the cornerstone to ensure the dimensional stability of the product. Once the dimensional accuracy of the winding machine does not meet the standard, the product size will appear large deviations, which not only can not meet the design requirements, but also seriously weaken the product performance and functionality.

2. Envelope accuracy: the envelope accuracy of the winding machine is directly related to the appearance of the product quality. If the envelope precision is not enough, the product surface will appear uneven, raised or sunken and other defects, which will greatly reduce the aesthetics of the product and the overall texture.

3. Tension accuracy: tension accuracy is an important indicator of the mechanical properties of the winding product. Uneven tension, too loose or too tight will lead to a decline in product strength and stability, thus affecting the overall performance and service life of the product.

4. Wire diameter accuracy: wire diameter accuracy is critical to the electrical properties of the wire-wound products. Wire diameter inconsistency will lead to resistance or inductance value of a large deviation, which in turn affects the product’s electrical properties and stability.

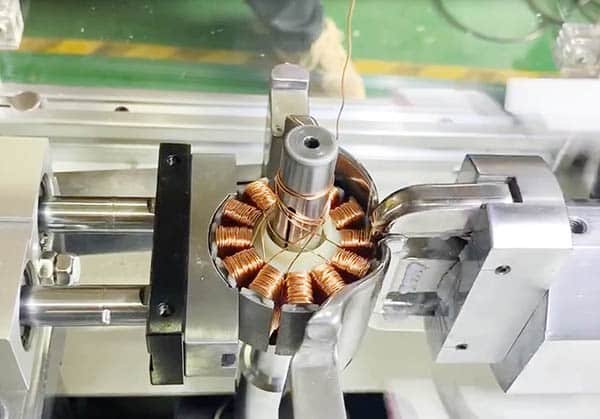

Second, the significant improvement in winding efficiency

1. Winding speed: high-precision winding machine can more accurately control the winding process, reducing the lack of precision and lead to repeated winding or correction time. This not only increases winding speed, but also significantly improves overall productivity.

2. Reduced Failure Rate: Winding machines with high accuracy are more stable in operation and have a lower failure rate. This reduces production interruptions due to broken wires, stuck wires and other problems, and further improves winding efficiency.

3. Increased automation: Highly accurate winding machines are usually equipped with more advanced automation control systems, enabling more efficient automated winding processes. This not only reduces manual intervention and labor costs, but also improves the consistency and stability of winding, which further improves production efficiency.

In summary, the accuracy of brushless winding machines has a crucial impact on the quality and efficiency of winding. Therefore, when choosing a winding machine, it is important to prioritize its accuracy index to ensure that the products produced meet the design requirements and improve production efficiency. At the same time, in the process of use, should also be regular maintenance and maintenance of the winding machine to maintain its accuracy and stability, so as to ensure that the production of sustained and efficient and product quality excellence.

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]