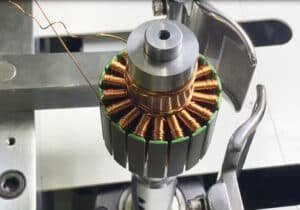

Brushless motor production process, there is an important part of the stator winding process, many friends also used manual winding, but the efficiency is relatively low, no way to encounter a large number of products, so the motor manufacturers use more specialized winding machine, to solve the problem of stator winding.

In fact, in the winding process, due to various reasons, such as machine configuration, operation, or environmental factors, sometimes encounter the problem of injury line breakage, so people are more headache, then the stator winding machine injury line breakage how to do? How to solve?

Stator winding machine wound line breakage causes.

1. Machine configuration is unreasonable, and the winding stator products do not match, can not keep up with demand.

2. The winding speed is too fast, whether it is coarse or fine wire, the winding speed has an upper limit, more than this speed, it may hurt the wire or even break the wire.

3. Tensioner setting is not reasonable, the tension setting is too large or too small, too large is easy to hurt the wire break, too small will lead to the enameled wire winding is not tight.

4. The skeleton and mold production process is rough, polishing and processing are not in line with the requirements, resulting in the enameled wire scraping, resulting in the phenomenon of wounded wire breakage.

In fact, the solution is relatively simple, do not be greedy for cheap, to buy inferior winding machine equipment, need to choose a reliable winding machine according to the product, the manufacturer’s after-sales service quality to be good, including delivery and installation training, and warranty, maintenance of these are in place, the important thing is that the operator is skilled in operation, can solve simple problems, all aspects are done, broken wire injury is less.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]