The automatic winding function can effectively improve efficiency! It is well known that the automatic processing capability of winding machines has improved. The control of winding machine is constantly applied to various high-end sensors, high-precision transmission parts, servo systems and other precision parts.

CNC winding machine control system is widely used. With automatic wiring function, it is suitable for various coil winding processes. The system integrates the functions commonly used in the winding process. The control circuit integrates the control and signal input of the equipment, and the application of the system can be configured at will.

The conductor wheel is one of the winding machine structures that comes into direct contact with the enameled wire. Different types of wire have different wire wheel configurations. Common winding processes include flat wire, single-stranded round wire, and multi-stranded round wire. Let’s talk about the application of these three winding process configurations of wire wheels.

Ring winding core is seamlessly rolled with high quality cold-rolled silicon steel plate (thickness 0.23mm-0.35mm), the magnetic circuit is completely closed and there is no magnetic leakage. Therefore, high precision laser welding, nitrogen-hydrogen protection vacuum annealing, the magnetic core electromagnetic index is greatly improved.

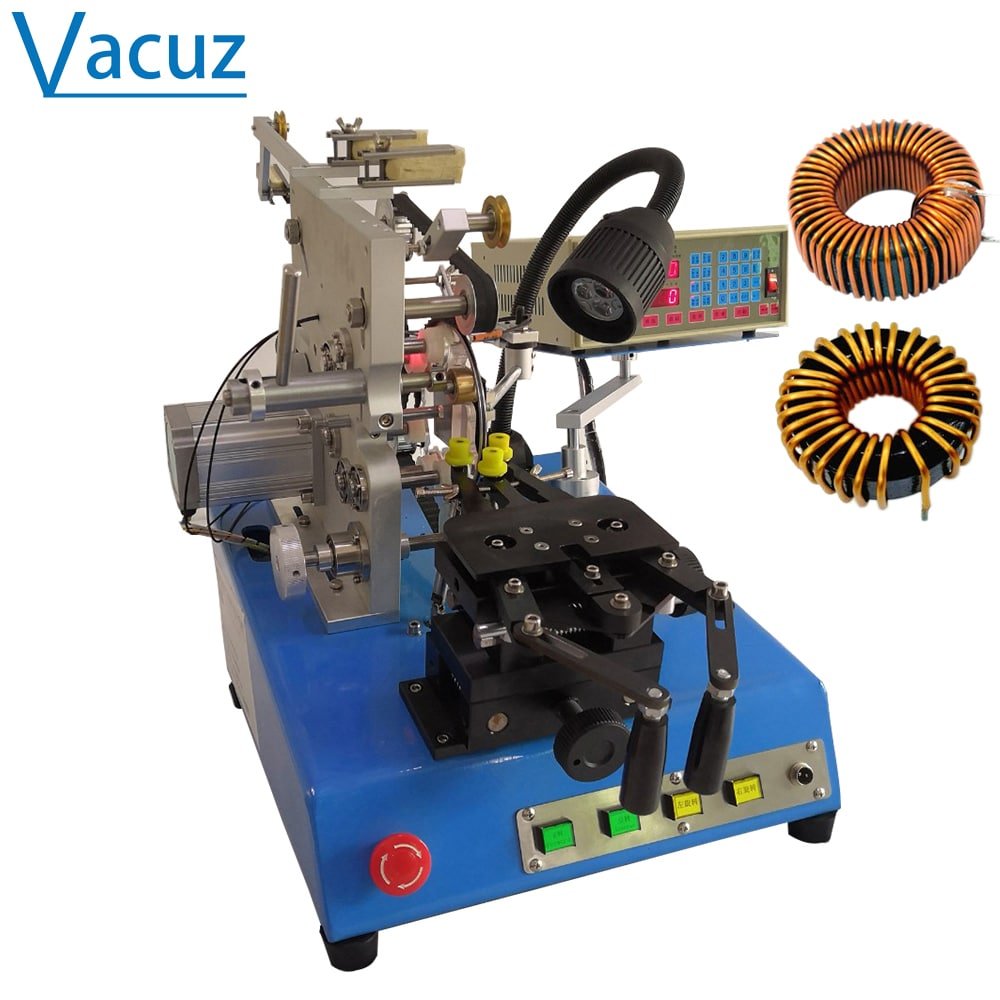

Ring type winding machine, high production efficiency, fast and convenient. Can be widely used in 50Hz.60Hz.400Hz transformers, transformers, reactors, chokes and other electronic equipment.

Factors affecting the winding tension.

1. Check the torque of the rotating part of the silk shuttle.

2. The moment of inertia caused by the change in acceleration (including the conductor wrapped in the bobbin). The main part of the frictional torque is generated by the tension mechanism, which prevents the wire shuttle from releasing and tensioning, thus creating winding tension. Due to the surface of the winding gear ring and its deviation from the center position of the winding gear, the moment of inertia caused by acceleration and winding tension is caused even if the winding is uniform.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]