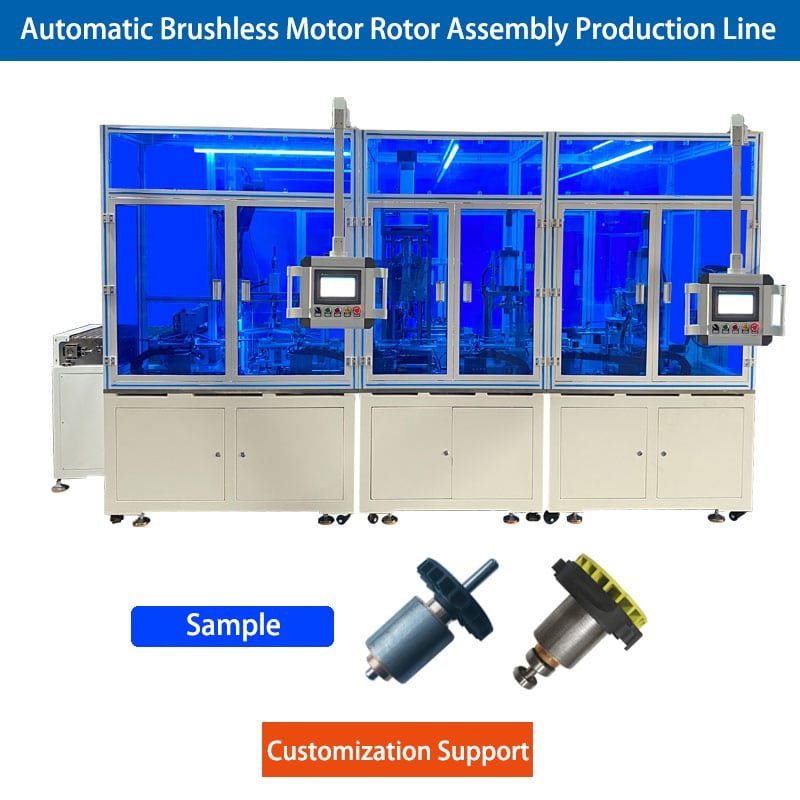

Many friends are curious about how the brushless motor stator is assembled, in fact, there are now specially customized automated production line, according to a certain production process, you can complete the assembly process of the stator, so what are the functional characteristics of the brushless stator automatic production line Vacuz to introduce to you!

1. The whole line uses imported servo motors and drive controllers as well as precision robots, which can realize automatic production, fast production beats and save a lot of labor costs.

2. Two accurate positioning to insert terminals, to ensure that the process of inserting terminals, there is no leakage of insertion and tilt.

3. It can automatically feed and wind the stator, winding precision, no wound wire, broken wire, jumping wire and other problems.

4. Adopt CCD vision system to detect the solder joint and cool the workpiece before the performance test.

5. It can automatically test the stator resistance, voltage resistance, inter-turn, pin conduction test, ambient temperature test, automatic compensation of any temperature, and automatic saving of test data.

6. It can realize the stator into the housing and online locking screw process.

The above is the advantages of brushless stator automatic production line, brushless stator automatic production line flexible use of online testing, performance testing and other functions, product consistency, high stability, quality control, quality CNC traceable, full potential for future development.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]