Stator coil winding, the need to use special winding equipment, winding equipment is also a variety of different products, winding methods, speed are different, so what is the role of high-speed brushless motor winding machine?

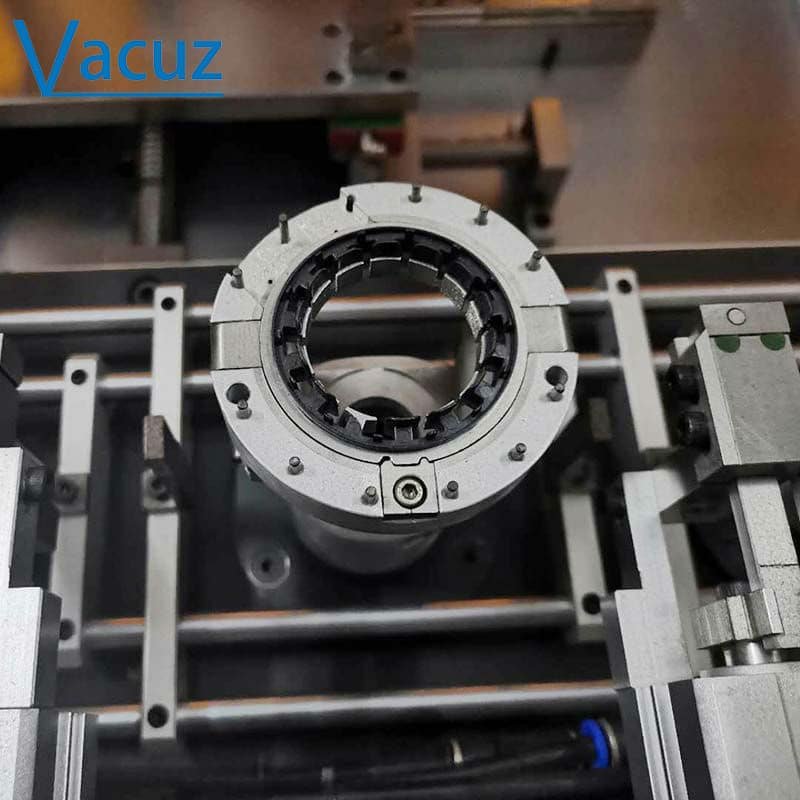

High-speed brushless motor winding machine, mainly for fine wire diameter, product outside diameter of smaller products, such as small pumps, blowers, stepper motors, industrial fans and other brushless motor stator, often four-station and six-station equipment, the speed can reach 1000RPM, high production efficiency, fast, in line with the motor production needs.

But occasionally in the use of high-speed winding machine, it is not very smooth, if the machine is not well tuned or some fault, because the wire diameter is small, so it is also very easy to break the line, so how to break the line? How to solve it?

1, the barrel is not correctly placed: the bottom of the large barrel is not well padded, winding wire scattered in the bottom of the barrel, may also damage the outer cover and barrel mouth. Check the bottom of the bobbin, fix it, and check whether there is a problem with the mouth of the bobbin.

2, the tension setting is not reasonable: winding machine tension setting is too large, is the main cause of wire breakage; if the tension setting is too high, will also cause wire breakage. Before setting and winding, it should be checked with spring balance according to the tension table.

3、Improper fit of the spring on the tensioning mechanism: When the spring force is high, it will pull off the copper wire. A suitable spring should be selected.

4、Improper setting of program parameters: too fast acceleration during winding, too fast hooking speed and poor fit will easily cause wire breakage. Parameters should be set to ensure correctness.

5, poor wire cutting mechanism: improper wire cutting, the tail line is easy to break at the beginning. The wire cutting mechanism should be reasonably adjusted.

High-speed winding machine broken wire how to do? These are the common causes and solutions, master these basic knowledge and principles to ensure stable and normal operation of the winding machine!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]