Why the capacitor of the automatic winding machine is damaged?Vacuz machinery and equipment to share with you, take a look!

Generally speaking, why does the capacitor of the winding machine become damaged? So how to solve this problem? It is actually very simple, it needs to wait for the capacitor to start, the current will suddenly appear a peak, and then I will very slowly down a small value, then the value will diarrhea leakage current, usually known as leakage, and then directly relative to the value of the voltage from zero increases slowly, and may lead to tilt plane, resulting in capacitor damage. Winding machine, wire binding machine and automatic winding machine manufacturers explain the damage to the wire binding mechanical container. Vacuz, the manufacturer of automatic winding machine, introduces the centralized speed regulation method and introduction of the winding equipment

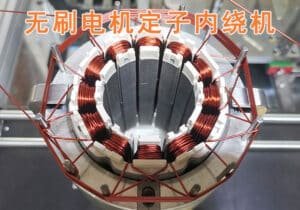

BLDC Motor Winding

1、Servo-driven motor speed regulation method

Servo motor has been used in recent years automatic winding machine, it belongs to the kind of precision moving parts suitable for high-precision winding equipment, it achieves closed-loop drive control for the operation, and the most striking constant torque characteristics of this type of motor, and closed-loop operation, can meet the requirements of various high-precision coil processing.

2、DC motor speed control

At present, we often see relatively DC motor has the following two types of brush DC and DC brushless DC motor requires the operation of power DC motor drive, therefore, and DC governor board or brushless DC motor driver drive control motor configuration, because the volume of small motor, so in smaller winding equipment should be relatively large.

3, AC motor speed control

AC motor which is our Z common motor, the motor itself does not have a speed control function, it needs an electromagnetic speed control device or inverter to achieve the speed control function, we often see on the winding device is a frequency converter speed control, however, through the winding equipment control system to control the inverter motor has the function of speed control, this way has a certain energy-saving effect.

We often see the winding machine, in order to adapt to the processing technology is required to configure the spindle speed adjustment, lifting equipment should be handled in different configurations are also different, relatively familiar with the type of AC motor spindle motor, DC motor, servo motor drive these three categories, the motor speed control method used has its own characteristics. Here is the equipment in combination with the winding machine speed regulation method.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com