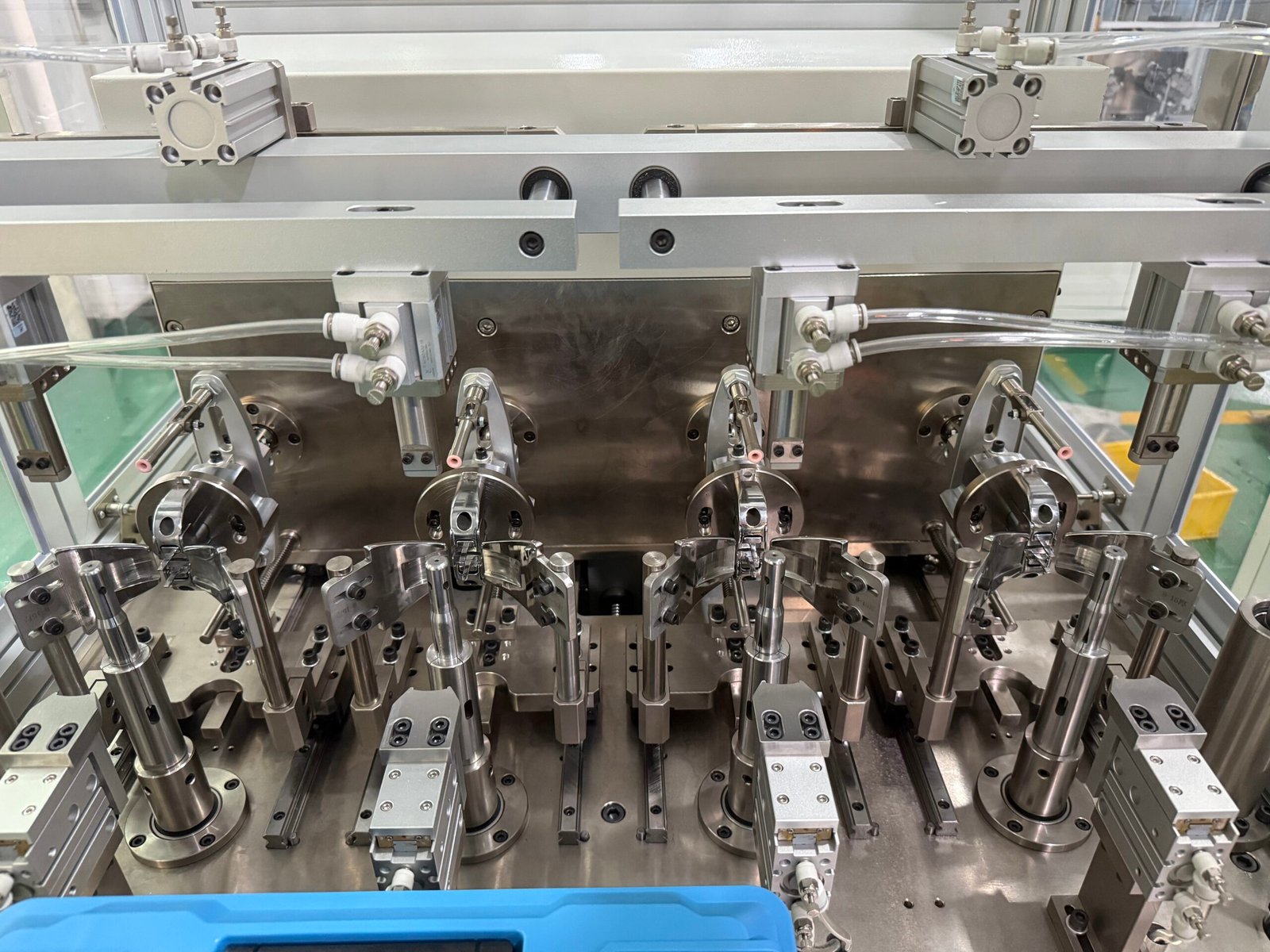

Vacuz 4 Stations DC Ceiling Fan Motor Automatic Outer Stator Coil Winding Machine Equipment

I. Core Design Requirements

1. High-Precision Machining: The tolerances of all mold components must be strictly controlled. For example, the notch dimension deviation must be ≤ ±0.02mm, and the surface must be polished to a smooth, burr-free finish to reduce wire friction.

2. Structural Adaptability: The mold must be customized according to the stator size and winding method to ensure interference-free assembly and disassembly.

3. Material Selection: The main body is constructed of high-strength alloy steel, achieving a hardness of HRC58-62 after heat treatment. The surface can be hard chrome plated or ceramic sprayed to enhance wear and corrosion resistance.

II. Key Design Details

1. Optimized Wire Passing and Stopping Areas: Designed arc guides prevent wire breakage, and positioning grooves ensure accurate wire end fixation.

2. Fastening and Anti-Loosening Design: A quick-clamping mechanism and anti-loosening screws ensure the mold remains stable and prevents loosening during the winding process.

III. User-Friendly Operation Design

1. Lightweight Structure: The mold weight is kept within a reasonable range, making it easy to carry manually.

2. Identification System: Information such as the stator model and winding parameters are engraved for quick identification and debugging.

IV. Environmental Adaptability Design

1. Temperature Control Design: An embedded temperature sensor monitors and controls the mold temperature in real time to prevent thermal deformation.

2. Dust-Proof Design: The design is enclosed, with dust covers installed at key locations and regular cleaning to maintain accuracy.

V. Verification and Optimization

1. Simulation Testing: Use CAD software to simulate mold motion and optimize mold design.

2. Actual Winding Test: Check indicators such as winding accuracy, wire arrangement quality, and wire damage rate, and adjust the mold design based on the test results.

Vacuz 4 Stations DC Ceiling Fan Motor Automatic Outer Stator Coil Winding Machine Equipment

How should the mold for a fully automatic stator winding machine be designed? What are the detailed requirements? Vacuz has provided a brief explanation, and we hope that it provides you with a clear understanding of mold design. If you have any other needs or feedback, please feel free to let Vacuz know.

E-mail: sales@vacuz.com

]]>

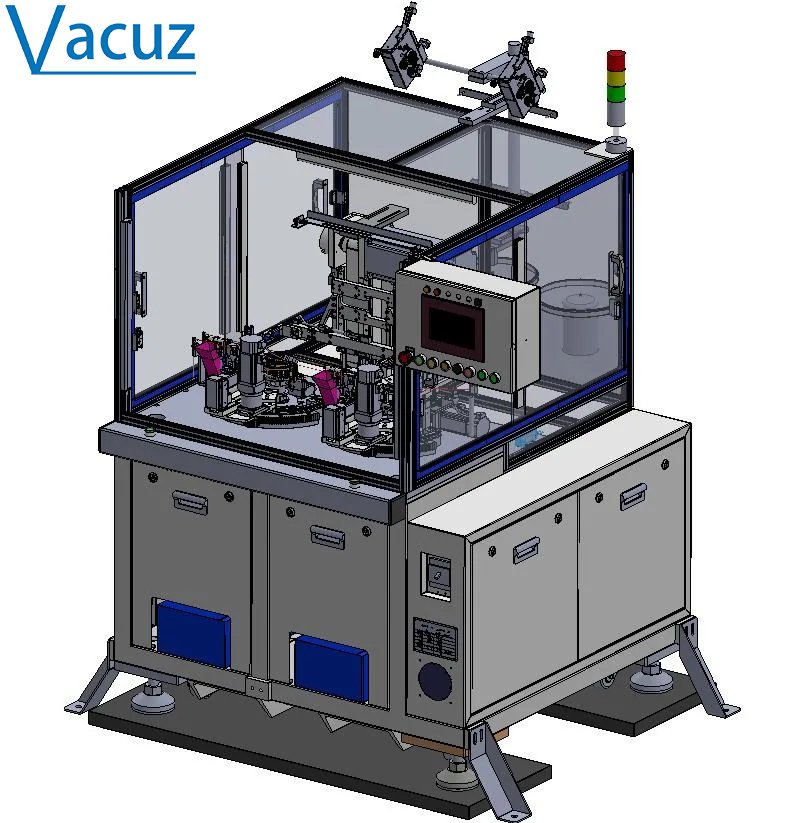

Vacuz dve stanice presného serva BLDC Brushless Motor E Bike Stator cievky Flying Fork Winding Machine

I. Core Requirements for Winding Machines

1. Mechanical Stability

Emphasis is placed on the selection of base and table materials, such as the thickness of the sheet metal base and the hardness of the stainless steel table, to ensure structural stability.

Provide specific mold machining accuracy specifications, such as surface roughness and tolerance range, to ensure high mold accuracy and positioning precision.

2. Control System Accuracy

List servo motor brands and models to help users select high-performance servo motors.

Detailed explanation of the coordinated control principles between the PLC motion controller and the servo system, such as achieving high-precision positioning through closed-loop control.

3. Tension Management System

Provide servo tensioner selection recommendations, such as selecting the appropriate tensioner model based on wire diameter and material.

Emphasize the importance of real-time tension monitoring and adjustment, and provide the working principle and debugging methods of the tension sensor.

4. Multi-station and Efficient Wire Arrangement

Provide flexibility in workstation design, such as specific implementation methods for supporting single-station, dual-station, or multi-station switching.

Detailed explanation of the advantages of servo-controlled layer arrangement, such as improved wire arrangement accuracy and reduced wire waste.

II. Applicable Conditions for External Winding

1. Stator Structural Characteristics

Provide reference data for stator outer diameter and stack height range to facilitate user selection of appropriate winding machine models.

Emphasis is placed on the impact of notch distance on winding accuracy and speed, and recommendations for optimizing notch distance are provided.

2. Wire Compatibility

Provide reference data for wire diameter ranges and explain the impact of different wire diameters on winding speed.

Emphasis is placed on issues that require attention when winding multiple wires in parallel, such as optimizing the winding path and reducing wire friction.

3. Environmental and Operating Requirements

Detailed explanation of specific installation environment requirements, such as floor flatness and the absence of vibration sources or high-temperature equipment.

Specific power and air source parameter requirements are provided to facilitate device configuration.

The importance of operating procedures is emphasized, and operator training plans and assessment criteria are provided.

4. Industry Application Scenarios

Examples of brushless stator flyer external winding applications in mainstream industries, such as medical, aviation, automotive, and drone motors, are listed.

Solutions are provided for special needs such as high-precision, high-efficiency, or non-standard stators, such as custom-made machines or precision wire routing equipment.

Two Sets Double Stations Drone Motor Automatic FPV Stator Core Winding Machines + Two Sets BLDC Drone FPV Rotor Core 2 Sides Dynamic Balancing Machines Shipment

What are the requirements for brushless stator flyer external winding machines? What are the applicable conditions for external winding? Vacuz has provided a brief explanation, and we hope this information will be helpful!

E-mail: sales@vacuz.com

]]>

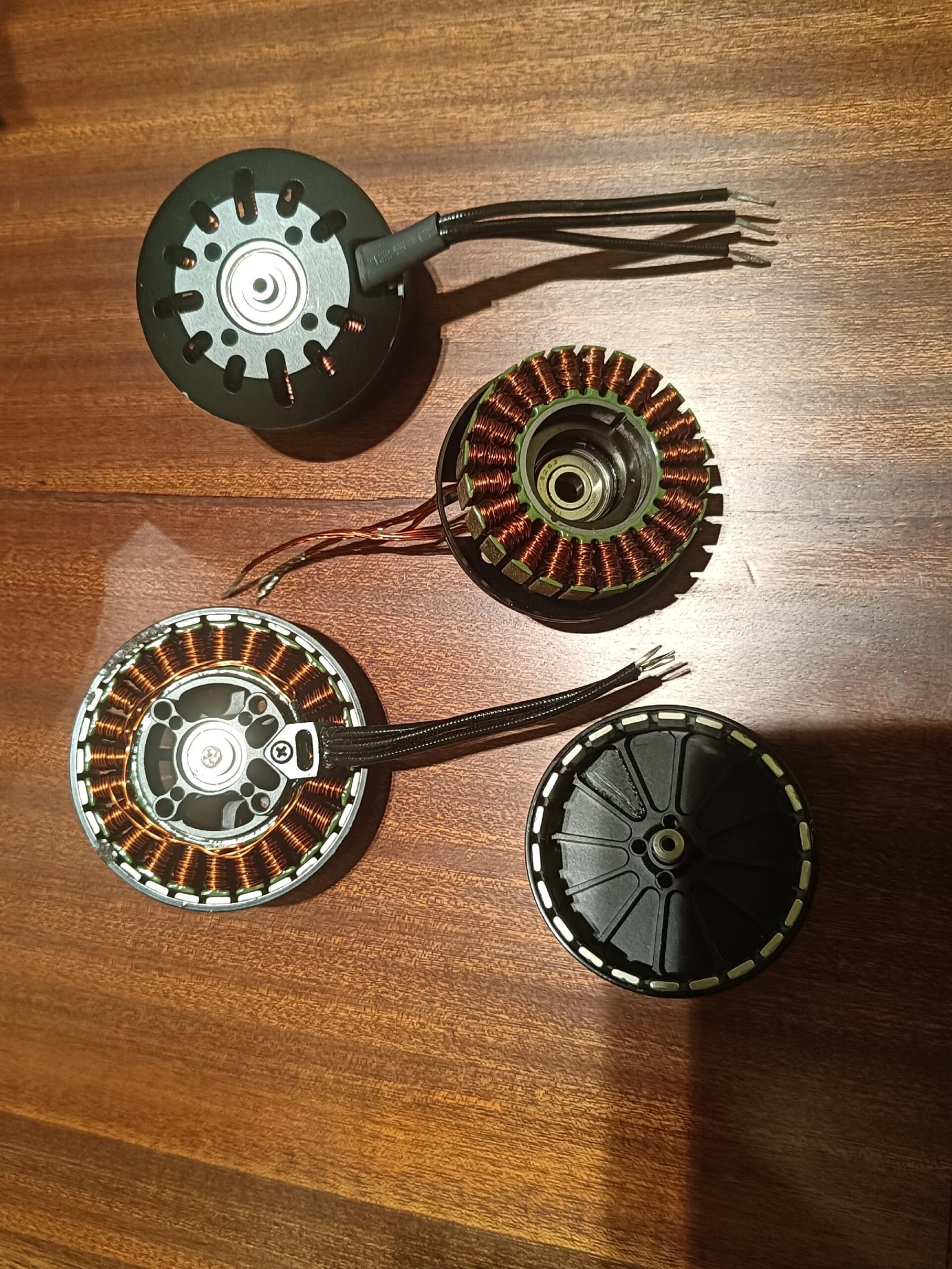

Prispôsobiť vysoko kvalitné Drone RC UAV BLDC Motor Core Lamination Fan Brushless Stator Laminated Electric Drone Motor Stator Core

I. Problems and Solutions Caused by Inadequate Equipment Precision

1. Mechanical Positioning Error

Problem Symptoms: Excessive coaxiality between the rotor core, shaft, commutator, and other components, resulting in excessive vibration or noise during operation.

Solutions:

Equipment Calibration: Use a laser alignment tool or micrometer to recalibrate the assembly tooling to ensure consistent positioning datums at each workstation.

Tooling Upgrade: Use high-precision pneumatic fixtures or hydraulic positioning devices to reduce mechanical backlash. For example, replace traditional V-blocks with self-centering chucks to maintain coaxiality within 0.01mm.

2. Sensor Signal Interference

Problem Symptoms: The visual inspection system misjudges part orientation or position, leading to assembly failure.

Solution:

Shielding interference sources: Install a metal shield on the sensor signal line, keeping it away from high-voltage motors or inverters.

Optimizing algorithms: Upgrade the visual inspection software and add anti-interference filtering capabilities. For example, use an edge detection algorithm instead of a grayscale threshold method to improve image recognition stability.

II. Problems and Solutions Caused by Improper Process Parameters

1. Improper Press Force Control

Problem Symptoms: Excessive press force can cause commutator collapse, while insufficient press force can cause poor contact.

Solution:

Dynamic force control: Use a servo press machine. Monitor the press process in real time using the pressure-displacement curve. Set the press force within the 500-800N range and automatically shut down to prevent sudden pressure changes.

Segmented press: For multi-layer rotors, use a multi-stage press process, with the pressure increasing by 10%-15% at each stage.

2. Heating temperature fluctuations

Problem Symptoms: Insufficient core expansion during shrink fit, resulting in interference fit failure.

Solution:

Closed-loop temperature control: Install infrared thermometers at the heating stations to provide real-time temperature feedback to the PLC controller, reducing the heating temperature fluctuation range to ±3°C.

Preheating buffer: Add a preheating station for large rotors to ensure a uniform core temperature rise and reduce thermal stress concentration.

III. Problems and solutions caused by part quality fluctuations

1. Poor dimensional consistency

Problem manifestation: Excessive shaft diameter leads to press-fit jams, or inconsistent commutator slot widths affect winding.

Solution:

Incoming material inspection: Add an automatic sorting machine to conduct 100% inspection of key dimensions and eliminate defective products.

Supplier collaboration: Sign a quality agreement with parts suppliers and require them to provide process capability analysis reports.

2. Surface defects

Problem manifestation: Burrs on the core laminations lead to excessive dynamic balance, or the commutator oxide layer affects conductivity.

Solution:

Online Cleaning: Add an ultrasonic cleaning station before assembly to remove oil, dirt, and burrs.

Plasma Treatment: Perform plasma cleaning on the commutator surface to increase surface activity and strengthen the bond with the enameled wire.

IV. Problems and Solutions Caused by Environmental Interference

1. Vibration Interference

Problem Symptoms: Equipment vibration during assembly can cause part displacement, such as misaligned magnets.

Solution:

Vibration Isolation Foundation: Install the assembly line on an independent vibration isolation platform, controlling the vibration acceleration to ≤ 0.05g.

Active Vibration Reduction: Use air-floating vibration isolation platforms for precision workstations, with an isolation frequency range of 1-100Hz.

2. Uncontrolled Temperature and Humidity

Problem Symptoms: High temperatures can cause grease deterioration, or high humidity can cause short circuits in electronic components.

Solution:

Constant Temperature Workshop: Maintain an assembly environment temperature of 20-25°C and a humidity of 40%-60%.

Local Protection: Add protective covers to sensitive workstations to prevent condensation.

V. Systematic Optimization Solutions

1. Digital Monitoring

Implementing an MES system: Collect equipment operating data in real time, generate SPC control charts, and predict equipment wear trends in advance.

Abnormal Warning: Set thresholds for key parameters to automatically trigger alarms and send notifications to maintenance personnel via a mobile app.

2. Error-Proofing Design (Poka-Yoke)

Part Poka-Yoke: Design asymmetric positioning structures for the shaft and commutator to prevent reverse assembly.

Process Interlocking: Automatically lock subsequent workstations if the preceding process fails.

3. Personnel Skill Improvement

Virtual Commissioning Training: Use VR technology to simulate the assembly process, allowing operators to familiarize themselves with equipment operation and error handling.

Standardized Operations: Develop SOPs to clearly define the operating procedures and parameter settings for each workstation.

Výrobná linka s rotorovou cievkou BLDC

We hope the above information provides effective solutions to the problems you may encounter during automated rotor assembly. If you have any other needs regarding assembly technology, equipment optimization, or process improvement, or if you have any feedback on the current content, please feel free to let Vacuz know so that we can provide you with more comprehensive support.

E-mail: sales@vacuz.com

]]>

Vacuz Precision Agriculture Drone Motor Automatic FPV UAV External 2812 3115 3520 Stator Core Winding Machine Equipment

1. Precision Requirements: Full-Process Control from Micron to System Level

Precision is crucial in automated rotor assembly. From core component machining to overall system-level control, high-precision technology and equipment are required.

Core Component Machining Accuracy: Magnetic assembly requires high-precision positioning to ensure uniform magnetic field distribution. Air gap uniformity is also crucial, as it directly impacts the motor’s vibration and noise levels. Furthermore, dynamic balancing is crucial for ensuring rotor stability at high speeds.

System-Level Accuracy: High-precision sensors, vision systems, and encoders enable real-time monitoring of key parameters such as press force, winding tension, and displacement. Furthermore, a closed-loop feedback control system allows for real-time adjustment of assembly parameters to ensure stability and accuracy throughout the entire assembly process.

II. Efficiency Requirements: Comprehensive Optimization from Second-Level Cycles to Flexible Production

In modern production, efficiency is a key indicator of production equipment performance. Automatic rotor assembly equipment can significantly improve production efficiency by optimizing cycle time and flexible production capacity.

High Cycle Time and Capacity: Mainstream equipment must achieve efficient production cycles to meet the demands of large-scale manufacturing. Optimizing workstation layout and equipment configuration can further shorten production cycle times.

Flexible Production and Rapid Changeover: The modular design allows for easy addition and removal of functional modules to accommodate diverse product requirements. Furthermore, the intelligent parameter switching system automatically calls assembly programs for different products, significantly reducing changeover time.

III. Common Equipment Types and Functional Analysis

Automatic rotor assembly equipment comes in a wide variety of types, each with its own distinct functions. The following are some common equipment types and their functional analysis:

1. Rotor Magnetization and Insertion Machine: This machine performs a series of processes, including press-fitting the rotor shaft, inserting magnets, weight removal and balancing, dynamic balancing measurement, magnetization, and assembly of the inner and outer rotors. Its high accuracy and efficiency have led to its widespread application in fields such as new energy vehicle motors and industrial servo motors.

2. Double Flying Fork Rotor Winding Machine: Its double flying fork structure enables high-speed winding, supporting single or multiple wires. Its highly accurate winding tension control and wire routing precision give it significant advantages in applications such as drone motors and high-speed hair dryer motors.

3. Dynamic Balancing Machine: This machine rotates the rotor at high speed and adjusts balance using laser weight removal or weight addition. Its high accuracy and rapid correction capabilities have made it widely used in applications such as automotive EPS motors and power tool motors.

IV. Technology Trends and Industry Practices

With the continuous advancement of technology, automatic rotor assembly production equipment is also undergoing continuous upgrades. The following are some current technology trends and industry practices:

AI-Enabled Quality Control: Through machine learning analysis of assembly data, equipment failures can be predicted and process parameters optimized. This intelligent quality control approach significantly improves production efficiency and product quality.

Digital Twin Technology: Simulating the assembly process in a virtual environment can proactively identify interference or collision issues, shortening equipment commissioning cycles. This technology allows equipment to be fully verified and optimized before production begins.

Green Manufacturing: Utilizing low-energy servo motors and energy recovery systems reduces energy consumption, aligning with carbon neutrality goals. This environmentally friendly production method not only contributes to sustainable business development but also helps protect our planet.

Výrobná linka statorových cievok motorov BLDC

In summary, automated rotor assembly equipment continues to evolve and advance in terms of precision, efficiency, equipment types, and technological trends. Vacuz hopes this information is helpful to you!

E-mail: sales@vacuz.com

]]>

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

I. The Core Differences Between Top and Bottom Winding

1. Winding Direction and Mold Positioning

Top Winding: The needle begins winding from the top of the stator. The nozzle moves up and down, driven by a servo motor, while the mold rotates left and right to arrange the wire. Initial mold positioning must be accurate to ensure the nozzle is aligned with the slot to prevent winding deviation.

Bottom Winding: The needle begins winding from the bottom of the stator. The principle is similar to top winding, but the mold’s rotation direction or initial angle may be adjusted to accommodate the spatial layout of the bottom winding.

2. Applicable Product Differences

Top Winding: Commonly used in stator products such as pumps, stepper motors, servo motors, household appliances, and medical devices. These products require high winding accuracy and slot fill rate.

Bottom Winding: Commonly used in stators for power tool motors and garden tool motors. Due to structural limitations or process requirements, these products may require bottom winding to optimize space utilization.

3. Equipment Configuration and Workstation Selection

Both types are available in two-, four-, or six-station configurations.

Bottom winding equipment may feature optimized die designs for thick wire or special slot shapes to reduce winding resistance.

Both types can achieve no-load speeds of up to 800 rpm, but actual winding speed is affected by wire diameter, number of slots, and wire density.

II. Differences in Wire Feeding Methods

1. Wire Feeding Path for Top Winding

After being drawn from the spool, the enameled wire passes through a tensioner and guide pulley into the needle bar nozzle. The nozzle drives the wire into the slot as the needle bar moves up and down.

As the die rotates, the nozzle must move back and forth synchronously to ensure the wire is arranged in layers within the slots, preventing overlap or damage.

Key Point: The coordinated movement of the nozzle and die requires high precision; otherwise, it can easily lead to chaotic wire routing or wire breakage.

2. Wire Path for Lower Winding

The enameled wire path is similar to that for upper winding, but the nozzle must enter the slots from below the stator. The die’s rotation direction or initial angle may need to be adjusted to accommodate the spatial layout of the lower winding.

For thick wire or unusual slot shapes, the nozzle may feature a wider design or special materials to reduce winding resistance and prevent wire damage.

Key Point: For lower winding, ensure that the wire does not interfere with the die, and the wire density must meet product performance requirements.

Selection Recommendation:

For products with high winding accuracy and slot fill requirements (such as medical devices and precision servo motors), upper winding equipment is preferred.

If your product has a thicker wire diameter or a special groove shape (such as in power tool motors) and you need to control costs, you may consider using a winding machine, but ensure the mold design can meet your wire routing requirements.

Vacuz Dual Stations BLDC Motor Automatic Inner Stator Core Needle Winding Machine Equipment Adjusting and Delivery

Vacuz hopes the above information meets your needs. If you have further questions about needle-type internal winding machines or related technologies, or if you have any feedback on this content, please feel free to let Vacuz know so that we can better serve you.

E-mail: sales@vacuz.com

]]>

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

I. Stable Operating Conditions

1. Reliable Grounding and Electrical Safety

Emphasize regular testing of ground resistance to ensure compliance with national standards and prevent electrical safety hazards.

Mention the use of safety devices such as leakage protectors to further enhance electrical safety.

2. Stable Working Environment

Detailed instructions on securing the workbench to the floor, such as using expansion screws, are provided to ensure the stability of the equipment.

Emphasize the importance of environmental isolation, such as installing isolation tape or protective covers to reduce external interference.

3. Appropriate Load Usage

Provide specific guidance on equipment load usage, such as developing a load usage table based on wire diameter and winding speed.

Emphasize the hazards of overloading, such as motor overheating and mechanical wear.

4. High-Quality Accessories and Systems

List the brands and models of core components to facilitate user selection of high-quality accessories.

Emphasize regular updates and upgrades to ensure optimal equipment performance.

5. Operator Professional Competence

Provide operator training plans and assessment standards to ensure operators possess professional skills.

Emphasize operator safety awareness, such as the wearing of personal protective equipment (PPE) such as safety glasses and gloves.

6. Factory Testing and Acceptance

Detail the specific items and standards for factory testing, such as winding accuracy, speed, and safety features.

Provide an acceptance report template to facilitate user equipment acceptance.

II. Methods for Meeting Winding Requirements

1. Accurately Setting Winding Parameters

Provide recommended settings for slow winding and slow stop parameters for start and stop, such as the number of slow winding turns and slow stop time.

Emphasize the importance of setting the cable routing and rotation direction, and provide detailed setting methods.

2. Multi-wire Parallel Winding Technology Optimization

Provides specific notch design dimensions and tolerances to facilitate notch processing.

Emphasis is placed on the importance of stack thickness control and provides methods for selecting and adjusting servo tensioners.

3. Precision Tension Management

Provides recommendations for servo tensioner selection, such as selecting the appropriate tensioner based on wire diameter and material.

Emphasis is placed on the importance of dynamic adjustment and provides reference ranges and frequencies for tension adjustment.

4. Enhanced Equipment Stability

Provides specific improvement measures for mechanical structure stability and precision transmission, such as strengthening the rigidity of the frame and chassis and using high-precision lead screws and guide rails.

Emphasis is placed on the importance of equipment commissioning and maintenance and provides professional commissioning and maintenance recommendations.

5. Process Optimization and Automation Upgrade

Provides specific methods and case studies for efficient winding path design.

Emphasis is placed on the principles and implementation of collaborative control between PLC motion controllers and servo systems.

Provides recommendations for upgrading automation functions, such as the implementation and application of touchscreen programming, automatic angle wrapping, and quick reset mechanisms.

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

What are the stable operating conditions for a fully automatic stator needle winding machine? How can winding requirements be met? Vacuz has briefly explained this above, and we hope this knowledge can be helpful to you!

E-mail: sales@vacuz.com

]]>#Vacuz

#StatorWindingMachine

#Toroidálne navíjanie

#CoilWindingMachine

1TP5Induktor navíjacieho stroja

#Transformátor navíjacieho stroja

#WindingMachine

#VacuzMachine

E-mail: sales@vacuz.com

]]>#Vacuz

#StatorWindingMachine

#Toroidálne navíjanie

#CoilWindingMachine

1TP5Induktor navíjacieho stroja

#Transformátor navíjacieho stroja

#WindingMachine

#VacuzMachine

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

Two Sets BLDC Motor Fully Automatic Stator Core Winding Lead Wire Managing Soldering Production Line Shipment

E-mail: sales@vacuz.com

]]>

Vacuz 2 Sets Double Stations Automatic FPV Drone Motor Stator Coil Flying Fork Winding Machines Shipping to India

Interoperability in brushless motor automatic winding machines is key to their efficient and accurate operation. This interoperability relies not only on the individual performance of each component, but also on the seamless coordination between them. Below, we will explore how to optimize interoperability in winding machines from six perspectives: mechanical configuration, control system, wire arrangement and die assembly, wire material characteristics, process parameter settings, and equipment maintenance and commissioning.

I. Core Factors and Optimization Directions

1. Mechanical Configuration Interoperability

Key Component Upgrades: Using high-precision lead screws from brands such as THK or HIWIN can significantly reduce transmission errors and ensure synchronization accuracy during the winding process. Furthermore, the mechanical structure’s rigidity must be designed to match the winding speed. Finite element analysis is used to optimize vibration modes to effectively prevent wire arrangement deviation caused by resonance.

Dynamic Balance: The dynamic balance of the equipment is particularly important in high-speed winding scenarios. Precise dynamic balancing testing and adjustment ensures stability and accuracy during high-speed operation.

2. Control System Integration

Improved Servo Control Precision: The application of a closed-loop servo control system enables real-time and accurate control of tension, speed, and position. Advanced algorithms such as PID control minimize tension fluctuations, significantly improving the synchronization of multi-wire winding.

Enhanced Multi-Axis Collaborative Control: A control system supporting at least four axes of coordinated operation achieves nanosecond-level communication latency through an efficient communication protocol, ensuring high-speed, high-precision motion trajectories.

2. Precision Coordination between the Wire Arrangement and Die Assembly

Mold Precision and Surface Treatment: The mold’s machining accuracy must meet high standards, and the surface must be hard-anodized to reduce friction and wear on the wire and extend the mold’s service life.

Optimized Wire Trapping Guide Design: Utilizing an advanced guide structure and adaptive tensioner, the system is compatible with various enameled wire diameters and enables dynamic and accurate adjustment of wire bundle spacing.

3. Accurate Matching of Wire Characteristics and Processing

Wire Diameter and Tension Matching Strategy: Selecting the appropriate tension range based on wire thickness ensures no wire breakage or loosening during the winding process.

Optimized Multi-Wire Parallel Winding Control: Accurately controlling the tension of each wire through independent tension control modules prevents coil eccentricity and loosening.

4. Collaborative Optimization of Process Parameters

Modeling the Triangular Relationship Between Speed, Tension, and Wire Trapping Speed: Parameter models are established through experiments to identify the optimal parameter combination to reduce wire breakage rates.

Application of Dynamic Compensation Algorithms: Combining accelerometer and encoder feedback to adjust tension output in real time, ensuring stable tension during spindle acceleration and deceleration.

5. Standardizing Equipment Maintenance and Commissioning

Developing a Preventive Maintenance Plan: Regularly inspect key maintenance items such as nozzle wear and tensioner accuracy to extend equipment life.

Optimizing the Full-Wrap Commissioning Process: Ensure that the wire harness is aligned and errors are kept within a small range through no-load running tests and gradual loading to rated tension.

II. Specific Practical Strategies for Improving Collaboration

1. Hardware Upgrade and Integration

Using integrated servo drives and high-resolution encoders improves position feedback accuracy and control performance.

2. Software Optimization and Innovation

Developing a dedicated process database supports one-click access to optimized parameter combinations; introducing digital twin technology reduces the cost of physical trial and error.

3. Human-Machine Collaboration and Training

Training operators to master parameter adjustment logic rather than relying solely on experience; establishing a fault warning system to proactively detect signs of decreased collaborability.

4. Standardized and Modular Design

Using international programming standards ensures program compatibility; designing a quick mold change device reduces mold change time.

Vacuz 2 Sets Double Stations Automatic FPV Drone Motor Stator Coil Flying Fork Winding Machines Shipping to India

What is the relationship between collaborability and the performance of brushless motor fully automatic winding machines? How can we achieve better collaboration? Vacuz has provided a brief explanation above. We hope this little knowledge can help you!

E-mail: sales@vacuz.com

]]>

Two Sets Double Stations Drone Motor Automatic FPV Stator Core Winding Machines + Two Sets BLDC Drone FPV Rotor Core 2 Sides Dynamic Balancing Machines Shipment

I. Improving Collaboration: Building a Closed-Loop Control System with Equipment Interoperability and Data-Driven Control

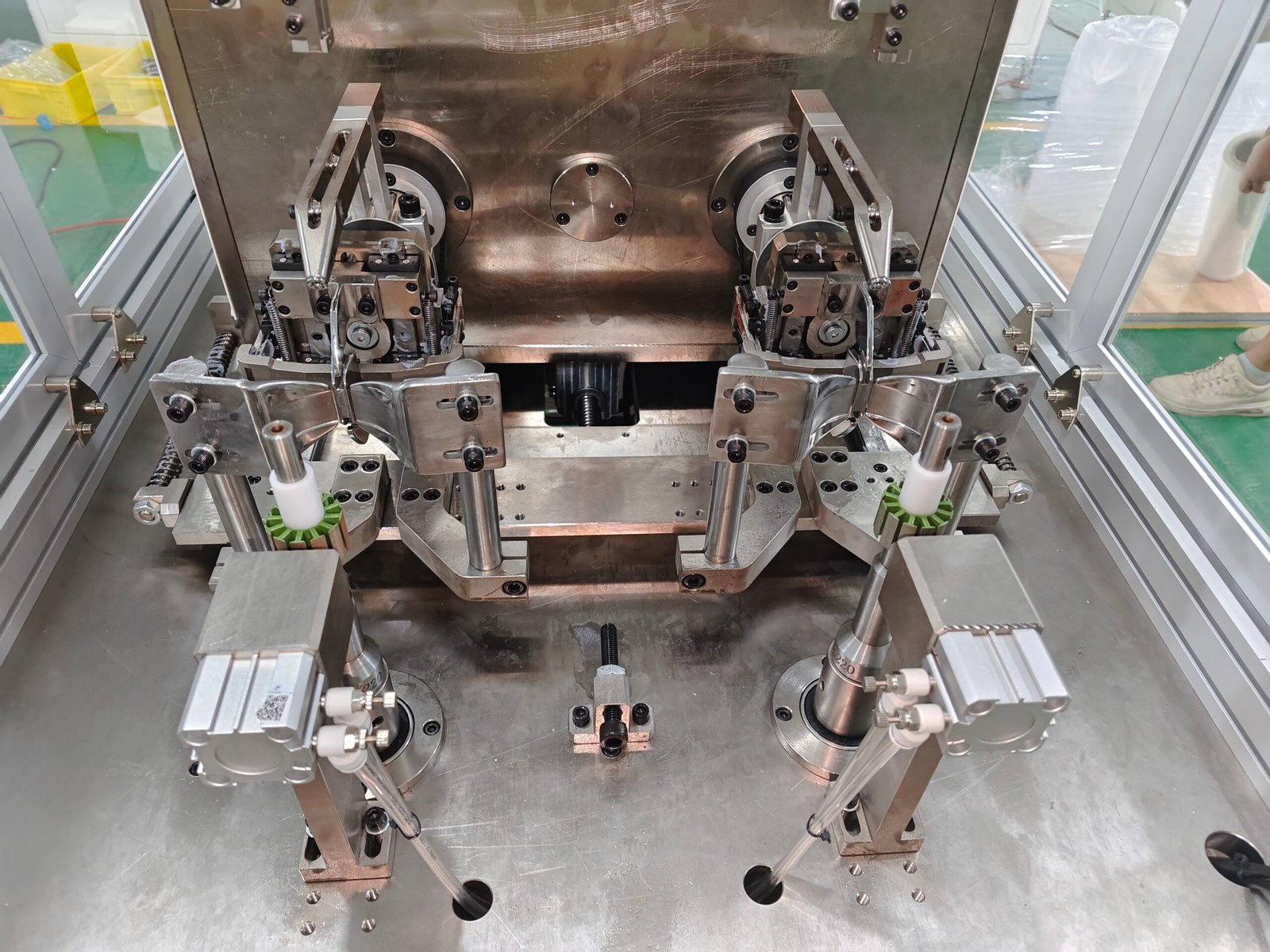

1. Hardware Collaboration

Modular Design: Utilizes standardized functional modules, such as shaft loading, magnetic press-fitting, and dynamic balancing testing. Quick-change tooling enables efficient switching of equipment functions, improving production line compatibility.

High-Precision Drive: Utilizes precision ball screws and linear guides, combined with high-speed servo motors, to ensure accurate multi-axis tracking, enhancing production efficiency and product quality.

2. Software Collaboration

Full-Process Data Collection: RFID technology enables material batch traceability, and PLC-based real-time data collection of key parameters provides data support for production decision-making.

Intelligent Scheduling Algorithm: Dynamically adjusts equipment cycle times based on production plans, balances loads across processes, and improves overall production line efficiency.

3. Human-Machine Collaboration

Error-Proofing Design: Installs error-proofing devices, such as photoelectric sensors, in key processes to reduce error rates.

Visual Monitoring: Builds a digital twin production line, mapping physical equipment status in real time to proactively identify and resolve problems.

II. Flexibility Optimization: Achieving Flexible Manufacturing and Adaptive Production

1. Equipment Flexibility

Multi-Station Parallel Operation: Designs multi-station parallel modules to improve production efficiency.

Rapid Mold Change Technology: Utilizes a pneumatic rapid clamping mechanism to shorten production line changeover time and enhance production flexibility.

2. Process Flexibility

Intelligent Adaptive Assembly System: Incorporates machine learning algorithms to automatically adjust assembly parameters, improving assembly accuracy and efficiency.

Vision-Guided Assembly: Incorporates high-resolution cameras and deep learning algorithms to accurately position parts.

3. Management Flexibility

Lean Layout Optimization: Adopting U-shaped or Cell-shaped production line designs shortens material handling distances and improves production efficiency.

Predictive Maintenance System: Using sensors and big data analytics to predict equipment failures, reducing failure rates and maintenance costs.

3. Assembly Precision Optimization: From Source Control to Full-Process Traceability

1. High-Precision Equipment and Process Control

Nano-Scale Machining Center: Using precision machine tools to machine key dimensions and ensure rotor dynamic balance.

Closed-Loop Tension Control: Real-time adjustment of wire tension during the winding process improves coil fill rate consistency.

2. Online Inspection and Feedback Correction

Multi-Parameter Testing Station: Integrates multiple sensors to monitor key parameters in real time to ensure assembly quality.

SPC Process Control: Implements statistical process control for key processes, analyzes process capability, and ensures product consistency.

3. Full-Process Traceability and Quality Control

MES Traceability System: Records production data for each rotor, supports batch or unit traceability, and improves the efficiency of locating quality issues.

Zero-Defect Management: Implements the PDCA cycle, combining error-proofing devices and online inspections to achieve zero-defect production.

Linka na výrobu motorov

How do you achieve coordination and flexibility in brushless rotor production lines? How can assembly accuracy be optimized? Vacuz has provided a brief explanation above. We hope this information is helpful!

E-mail: sales@vacuz.com

]]>