The AC motor is the more widely used motor for the winding machine and automatic winding machine operation of the automatic winding machine manufacturer. The AC motor of the winding machine in practice operation, the life span is relatively long, generally is not easy to damage. However, the number of AC motors in practice is large, so it is often found that the number of winding machine AC motor damage is still a lot, which is why most of the motor repair is AC motor repair. AC motor winding maintenance skills, mainly on the basis of understanding and grasping the underlying operating principles, learn to analyze the various AC motor winding flip chart.

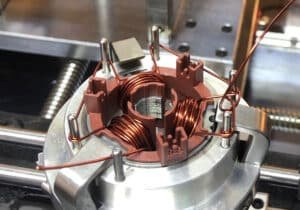

Automatic winding machine is a machine that winds wire-like objects onto specific workpieces. It is used in electric sound enterprises. But most of the electrical products need to use enameled copper wire (referred to as enameled wire) winding into inductive coils, you need to use the winding machine. For example: various electric motors, fluorescent lamp ballasts, various sizes of transformers, television sets. Radio with mid-cycle, inductor coil, line output transformer (high-voltage package), electronic ignition, mosquito extinguisher on the high-voltage coil, speakers, headphones, microphone voice coil, a variety of electric welding machine, etc. can not be cited, these coils are required to wind the coil with automatic winding machine manufacturers.

Navíjanie cievky

Only need to understand and grasp the manufacture of winding machine winding open diagram, and then after the original (old) motor or manual, to obtain some parameters on the motor winding open diagram, manufacturing winding open diagram, then in practice, according to the diagram, AC motor winding repair skills are not very difficult. The main effect of the stator winding is the onset of the rotating magnetic field, the electrical energy absorbed from the power supply is transferred to the rotor through the rotating magnetic field in order to drag the mechanical load Is line of work, that is, to complete the conversion of electrical energy into mechanical energy; so, in the AC motor, the stator is called the armature, the stator winding is called the armature winding. Most of the rotor windings are cage rotor guide bars, which generally do not present great problems; the other few are wirewound, and the winding machine winding placement skills are the same as the stator root. Therefore, in the maintenance skills of the winding machine AC motor winding, to catch the winding onset of rotating magnetic field this main line.

Non-dense row of coil winding needs to determine the distance between the line and the line according to the requirements of the winding process parameters, this parameter will be used directly for winding machine control parameters set; determine the parameters we need to wind the machine accessories for certain debugging and settings, tension settings must be less than the conventional winding, winding spindle speed settings are also very important, the spindle speed must be selected low speed to prevent the presentation of the line and The spindle speed must be set at a low speed to prevent the loss of step between the line and the spindle.

Non-dense row of coils using automatic winding machine manufacturers of automatic winding machine winding process is now very sophisticated, the user needs to pay special attention to the winding process is the setting of the winding parameters, the adjustment of the supporting accessories and various auxiliary operations in the winding process.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com