The assembly of brushless motor stator and rotor is a rather troublesome problem. Nowadays, special automated production lines are mostly used for assembly. However, the production line configuration standards are quite particular. Every link is important. So what are the configuration standards of brushless motor stator and rotor production lines? How to choose high-quality spare parts? Vacuz will introduce it to you!

Linija za proizvodnjo motorjev

I. Configuration standards of brushless motor stator and rotor production lines

1. Equipment selection

(1) Select a suitable winding machine according to production needs, such as inner winding stator winding machine, outer winding stator winding machine, etc.

(2) Select high-precision molds and configurations to ensure the accuracy and speed of winding.

(3) Equipped with professional servo control systems and high-quality spare parts to improve the automation and stability of the production line.

2. Process parameters

(1) According to the parameters of the stator frame and enameled wire, set the appropriate winding process parameters, including outer diameter, inner diameter, stack thickness, wire diameter, number of coil turns, number of slots, etc.

(2) Consider the feasibility of winding multiple wires in parallel to improve production efficiency and product quality.

3. Production line layout

(1) Rationally plan the layout of the production line to ensure smooth connection between equipment and reduce material handling and waiting time.

(2) Equip with necessary testing equipment and tools, such as tensioners, photoelectric encoders, laser sensors, etc., to monitor the winding quality in real time.

4. Automation and intelligence

(1) Introduce automation and intelligent technologies, such as machine vision systems, AI image recognition technology, etc., to achieve automatic detection of winding quality and fault warning.

(2) Use industrial robot technology to improve the automation level and production efficiency of the production line.

5. Quality control

(1) Establish a complete quality management system and strictly control all links in the production process.

(2) Regularly maintain and service the equipment to ensure that the equipment is in good working condition.

II. How to choose high-quality spare parts

1. Brand and reputation

Choose well-known brands and reputable suppliers to ensure the quality and reliability of spare parts.

You can learn about the brand and reputation of the supplier by reading industry reports, consulting professionals or referring to user reviews.

2. Performance and parameters

According to the configuration standards and process parameters of the production line, select parts with matching performance.

Pay attention to the performance indicators of parts such as precision, strength, wear resistance, and corrosion resistance to ensure that they can meet production needs.

3. Price and cost performance

Consider the price and cost performance of parts while ensuring quality.

You can choose the parts with the highest cost performance by comparing the prices and performance of different suppliers.

4. After-sales service

Choose a supplier that provides perfect after-sales service so that problems with parts can be solved in time.

Understand the supplier’s after-sales service policy, maintenance capabilities, and response time to ensure that production needs can be met.

5. Compatibility and replaceability

Choose parts that are compatible with existing equipment to ensure that they can be easily installed and replaced.

Consider the standardization and versatility of parts so that alternative products can be easily found when needed.

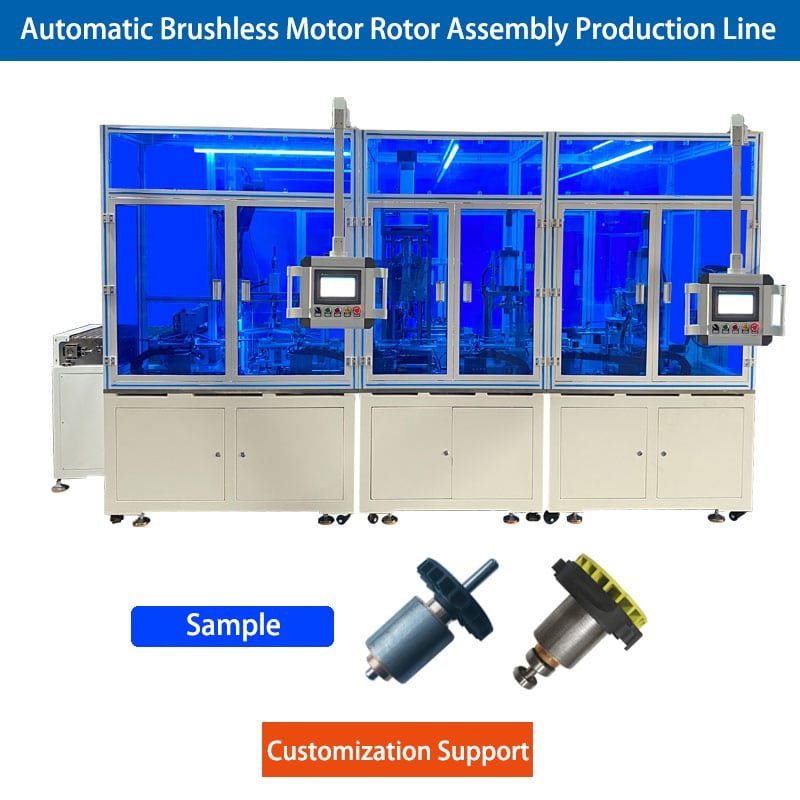

Avtomatska proizvodna linija za montažo rotorja brezkrtačnega motorja

What are the configuration standards for brushless motor stator and rotor production lines? How to choose high-quality parts? Vacuz has made a simple explanation above. I hope these little knowledge can help you!

E-naslov: sales@vacuz.com