The full slot rate of brushless motor stator winding is a comprehensive indicator, which is affected by winding process, equipment configuration, material selection and design parameters. The following is an in-depth discussion of these influencing factors and optimization strategies by Vacuz:

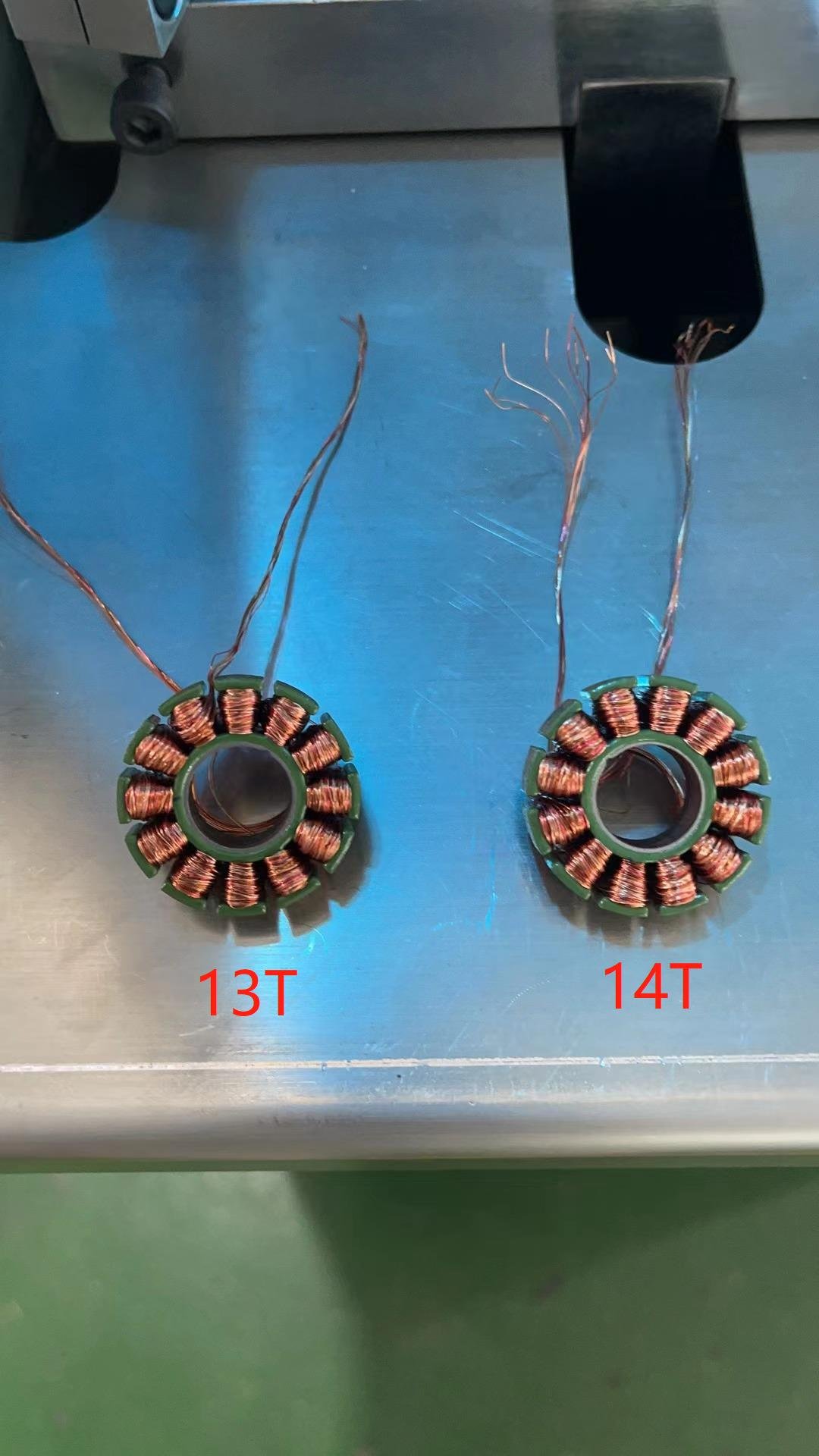

Vacuz Visoka natančnost Avtomatski 0,2 mm 1314T Drone Motor BLDC Brushless Zunanji stator tuljave navijanje strojni vzorec

1. Key factors affecting the full slot rate of brushless motor stator winding

1. Winding process and equipment

Winding method: The inner winding machine and the flying fork outer winding machine are suitable for stators with slots facing inward and outward respectively. Choosing the right winding method is crucial to achieving a high slot full rate.

Tension control: Reasonable tension control can ensure that the wires are closely arranged and effectively reduce the gaps, thereby improving the slot full rate.

Wire arrangement accuracy: A high-precision wire arrangement system can significantly reduce the overlap and gaps of the wires, further improving the filling rate in the slot.

2. Stator design parameters

Slot type and size: The geometry and effective cross-sectional area of the slot have a direct impact on the slot full rate. For example, trapezoidal and rectangular slots have different characteristics when filling wires.

Slot insulation material: The thickness of the insulation layer will occupy the space in the slot, so it is necessary to balance the insulation performance and slot fill rate.

3. Wire parameters

Wire diameter and material: Thin wire diameter can increase the number of wires in the slot, but the thickness of the insulation layer and the heat dissipation performance also need to be considered. Wires of different materials (such as copper wire and aluminum wire) also affect the slot fill rate.

Number of parallel windings: Multi-wire parallel winding can increase the slot fill rate, but the winding machine is required to have a synchronous winding function to avoid wire misalignment.

4. Winding parameters

Number of turns and layers: An increase in the number of turns will increase the slot fill rate, but too many turns may lead to insufficient insulation between layers and increase the risk of short circuits.

Winding speed: High-speed winding may affect the neatness of the wire arrangement, so it needs to be matched with the equipment accuracy.

2. Specific requirements for winding machine equipment configuration

1. Equipment selection

Slot direction: Select a suitable winding machine according to the slot direction of the stator. Select an inner winding machine for slots facing inward and a flying fork outer winding machine for slots facing outward.

Stator size: Select the appropriate number of stations and equipment type according to the outer diameter, inner diameter and stacking thickness range of the stator.

2. Winding function

Tension control: Configure a tension control system to ensure stable wire tension to adapt to wires of different wire diameters.

Synchronous winding: For the case of multi-wire winding, the winding machine needs to have a synchronous winding function.

Wire arrangement system: A complex wire arrangement system can achieve uniform arrangement of multiple wires, further improving the slot fill rate.

3. Material adaptability

Wire diameter matching: Select the appropriate type of winding machine according to the wire diameter range.

Material compatibility: Ensure that the winding machine is compatible with wires of different materials and adjust the corresponding process parameters.

4. Production efficiency and quality

Winding speed: Under the premise of ensuring the accuracy of wire arrangement, increase the winding speed to improve production efficiency.

Quality inspection: Configure the slot full rate detection function to ensure that the winding quality meets the design requirements.

III. Specific suggestions for slot full rate optimization

1. Magnetic circuit design: By optimizing the magnetic circuit structure and reducing the number of slots, the slot full rate can be effectively improved.

2. Heat dissipation design: High slot full rate may lead to aggravated heat dissipation problems, so it is necessary to strengthen the heat dissipation design to avoid excessive temperature rise.

3. Insulation design: Use thin insulation materials to improve the slot full rate while maintaining insulation performance.

4. Manufacturing process: Use precision winding technology to reduce the wire gap and further improve the slot full rate.

Vacuz Two Stations BLDC Brushless Drone Motor Stator Coil Flying Fork Winding Machine Delivery

In summary, the improvement of the stator winding slot full rate of brushless motors requires comprehensive consideration of winding process, equipment configuration, material selection, design parameters and other factors. By synergistically optimizing these factors, a balance between high slot fill rate and winding quality can be achieved, thereby improving the performance and reliability of the brushless motor.

E-naslov: sales@vacuz.com