In the field of motor manufacturing, stator winding is a crucial link. The application of stator automatic winding machine improves winding efficiency and product quality. Vacuz will introduce in detail the working principle of stator automatic winding machine and the differences between different winding machines.

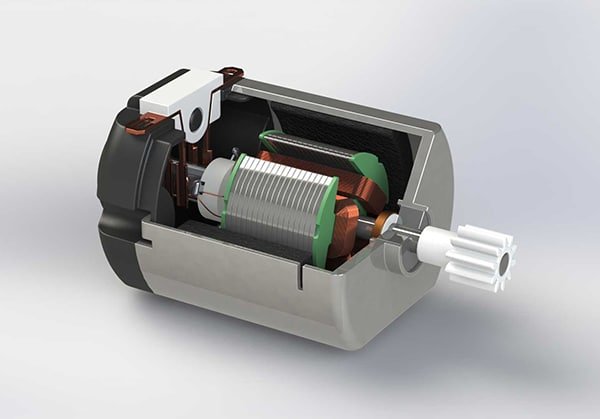

BLDC Motor

1. Working principle of stator automatic winding machine

The stator automatic winding machine efficiently completes the winding work of the motor stator through a series of accurate operating steps. Its working principle mainly includes the following stages:

1. Preparation

Place the motor stator on the workbench of the winding machine and fix it with a clamp to ensure that it will not move during the winding process. At the same time, connect the winding machine to the power supply to power the equipment.

2. Winding preparation

Adjust the winding molds on the winding machine according to actual needs. These molds determine the wire diameter, number of turns and layout of the winding. Only after ensuring that the mold is set correctly can the subsequent winding work be carried out.

3. Winding process

After starting the winding machine, its electric main drive device will drive the winding turntable to rotate. The wire is guided from the wire paper rack to the motor stator through the winding head. The winding head is equipped with a wire clamping device and a winding tool. The wire will be clamped and cut off after passing through the winding head. As the motor stator rotates, the wire will be wound according to the predetermined number of turns and layout.

4. Winding completion

When the winding reaches the predetermined number of turns, the winding machine will automatically stop working. At this time, the end of the winding wire will be cut off, and the winding on the stator will be fixed in a specific position. At this point, a complete winding process is over.

2. The difference between different winding machines

In the field of motor manufacturing, there are many types of winding machines to choose from. Different types of winding machines have significant differences in structure, function and application areas. The following are several common winding machines and their characteristics:

1. Fully automatic winding machine

Fully automatic winding machines meet the production needs of high efficiency and high output. It generally adopts a multi-head linkage design and a programmable controller as the control core, and has functions such as automatic wiring, automatic foot winding, automatic wire cutting, and automatic loading and unloading of skeletons. This type of winding machine reduces dependence on manual labor and improves production efficiency.

2. Servo precision winding machine

Servo precision winding machine is the product of the combination of high and new technologies. Its main shaft and cable arrangement are both equipped with high-precision servo motors, and the control system uses a PLC system with high computing power. This winding machine has functions such as automatic calculation, automatic discrimination, error correction, etc., and advanced accessory devices, such as auxiliary mold unloading device, active tension pay-off frame, electromagnetic automatic adjustment tensioner, etc. It is suitable for application scenarios with high winding accuracy requirements.

In addition, there are other types of winding machines such as brushless motor outer winding machine, brushless motor inner winding machine, etc., each of which is designed for different application scenarios and winding requirements.

Precision Lineup Automotive Motor Two Spindles Automatic BLDC Brushless Outer Stator Coil 2 Stations Flying Fork Winding Machine

In summary, the stator automatic winding machine efficiently completes the winding work of the motor stator through accurate operating steps. However, different types of winding machines have significant differences in structure, function and application field. When choosing a winding machine, it is necessary to make comprehensive considerations based on specific production needs and product characteristics. By choosing a suitable winding machine, production efficiency can be significantly improved, costs can be reduced and product quality can be improved.

E-naslov: sales@vacuz.com