Wire winding machine is a kind of automated equipment widely used in electronics, electrical, communication, automobile and other fields. It can quickly and accurately wind wires or harnesses into stable coils under certain specifications and length requirements. Below is a guide on how to use a coil winding machine, totaling 900 words.

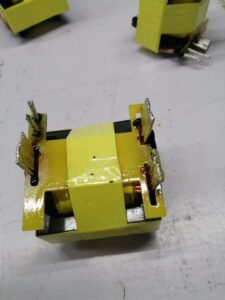

EPC EFD Transformer Bobbin Coil Vacuz Automatic Winding Taping Casing Machine Produce

First: Preparation

1. Configure the workbench: Make sure the workbench is flat, neat, and has the required winding tools and materials.

2. Check the bobbin winder: Make sure that the bobbin winder is properly connected to the power supply, that all safety devices are complete, and that there is no damage to the mechanical parts.

Next 1. set up the winding parameters: adjust the parameters of the winding machine, such as wire diameter, coil diameter, number of coils, etc., according to the requirements.

2. Select appropriate winding head: According to the required wire diameter and coil diameter, select appropriate winding head and install it on the winding machine.

3. Adjust the position of the winding head: According to the coil diameter, adjust the position of the winding head to ensure that the wire can pass through the winding head smoothly.

Step 3: Prepare the wire

1. Prepare wire material: according to the requirements of winding, select the appropriate wire material, make sure its quality is reliable, the length is enough, and clean up the surface of the wire.

2. Position the starting point of the wire: Place the starting point of the wire in a suitable position so that it can pass directly through the winding head.

Step 4: Start winding

1. Start the winder: Start the winder according to the operation guide of the winder to ensure safe operation and wait for the winder to be in normal working condition.

2. Guide the wire: Hold the wire, take care to maintain proper tension, guide the wire vertically through the winding head to avoid kinking or tangling of the wire.

Step 5: Monitor the winding process

1. Observe the winding situation: Always pay close attention to the parameters of wire diameter, coil diameter and coil quantity during the winding process to ensure compliance with the requirements.

2. Check the quality of winding: regularly check whether the wound coils are even and tight, with no looseness or misalignment, and make adjustments if necessary.

Step 6: Finish winding

1. Finish winding: When the winding machine finishes the required number of coils or preset winding length, stop the operation of the winding machine and turn off the power in time.

2. Trimming the wire: Fix the wound coils as needed and trim the end of the wire to make it neat and regular.

Step 7: Cleaning and Maintenance

1. Clean the workbench: Clean the workbench and store the winding tools and materials for next time use.

2. Maintain the winding machine: clean the mechanical parts of the winding machine regularly, lubricate the moving parts, and check the function of each safety device.

12 Spindles Automatic Transformer Coil Needle Winding Taping Machine

The above is a brief guide on how to use the bobbin winder. When using the bobbin winder, please follow the operating instructions and safety regulations, and make specific adjustments and operations according to the actual situation.

WhatsApp/Wechat: +86 13075286997

E-post: sales@vacuz.com