Motor stator winding wire injury is a headache, some friends encountered, may not know what is going on, so what exactly causes it? How to avoid motor stator wound wire? What are the methods to solve the injury line Vacuz simple to introduce it to you! I hope it can help everyone!

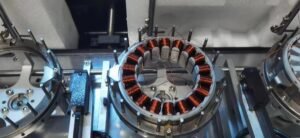

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

In fact, the motor stator winding wire injury, there are many reasons, such as winding parameter settings, machine stability is not good, the machine configuration is too poor, mold polishing is not good, the skeleton does not meet the requirements, the tensioner is not set up, the winding speed is too fast and so on, these situations may cause the stator wire injury.

Reasonable to avoid the problem of wire wounding is very important:

1. Tension control should be reasonable, the tension should be uniform, neither too large nor too small, too much tension can easily lead to broken or damaged, resulting in defective products.

2. Each winding parameter setting must be correct. Generally speaking, different models of products have special winding programs provided by the manufacturer, which can be directly imported and called.

3. The control of winding speed is also very critical. Too fast speed may cause enameled wire breakage and injury. Therefore, the speed should be adjusted to the appropriate range according to the instructions of the manufacturer of the winding machine.

4. The precision and configuration of the winding machine are also important factors affecting wire damage. The winding machine needs to be equipped with professional motor drives, cylinders, screws, guide rails and so on. If the basic configuration can not meet the product requirements, it may cause the wire tightness is not enough, thus causing damage to the wire.

During operation, if the brushless motor winding machine fails, it should be stopped in time to identify the cause and solve the problem. It cannot be forced to run. At the same time, the winding machine must be operated according to the regulations and pay attention to personal safety.

In addition to the above measures, you can also take some specific solutions to deal with the problem of enameled wire injury. For example, you can debug the machine to make sure the parts are positioned accurately and without offset. After completing the winding, perform a salt water test to check if the stator meets the requirements. If not, readjust it to ensure that the die is polished and finished as required.

Four Stations Automatic BLDC Brushless Inner Motor Stator Coil Needle Winding Machine

How to avoid wire winding in motor stator winding? What are the methods to solve the wounding Vacuz above has done a simple explanation, I hope that this little knowledge can help you!

E-post: sales@vacuz.com