The versatility of the motor stator winding machine is undoubtedly a core consideration in the manufacturing process. It not only affects whether the equipment can flexibly cope with various types and specifications of stators, but also directly affects the rapid changeover capability and overall efficiency stability of the production line. In order to ensure the versatility and winding quality of the winding machine at the same time, Vacuz will briefly introduce it to you below!

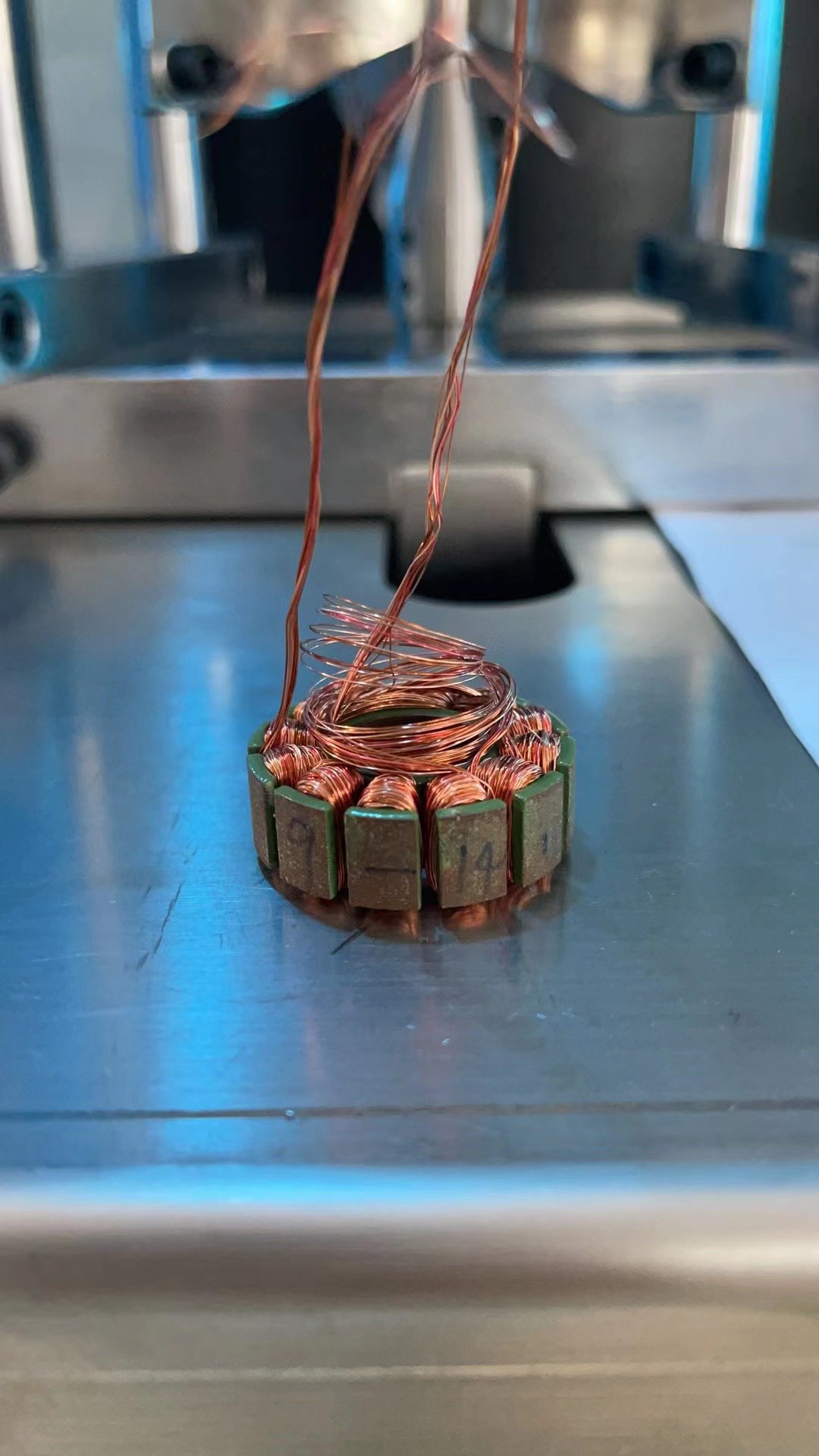

Vacuz hög precision automatisk 0,2 mm 1314T drönare motor BLDC borstlös yttre stator spole lindningsmaskin prov

1. Selection and exquisite design of equipment

When choosing a winding machine, priority should be given to those models with flexible and changeable designs and high modularity. Such equipment can often adapt to a variety of stator models more easily. Needle-type internal winding machines and flying fork winding machines are the preferred choice for stators with various slot directions due to their excellent versatility. In the equipment configuration and debugging process, it is necessary to ensure that all key components, such as servo motors and PLC controllers, have stable and reliable performance. During the debugging process, the program parameters must be carefully optimized to ensure the coordinated operation of various components, thereby improving the stability of the equipment and the winding accuracy.

2. Ingenious conception of molds and tooling

The universal design of the mold is crucial, and it should be able to quickly adapt to the replacement of stators of different models. The mold structure should be simple and clear, easy to install and disassemble quickly, so as to shorten the changeover time. At the same time, the design of the tooling should also be tailored according to the size, shape and winding requirements of the stator to ensure that the stator is stable and immobile during the winding process. The selection of tooling materials is also critical, and it must have good wear resistance and corrosion resistance to extend the service life.

3. Fine control of winding process and quality

The optimization of the winding process needs to be closely combined with the specific model and winding requirements of the stator to formulate a scientific and reasonable process plan. During the winding process, key parameters such as speed, tension and arrangement should be strictly controlled to ensure that the coils are arranged tightly and consistently. In addition, a complete quality inspection system should be established to conduct a comprehensive inspection of the stator after winding, and timely handle and analyze the problems found, so as to continuously optimize the winding process and equipment performance.

4. Thoughtful arrangements for operation and maintenance

Operators need to receive systematic training, master the operation methods and safety regulations of the equipment, and ensure personal safety and normal operation of the equipment. At the same time, a detailed equipment maintenance plan should be formulated to regularly clean, lubricate and inspect the equipment. Once a fault or problem is found, it should be repaired and handled immediately to ensure the stability and reliability of the equipment.

Precision Lineup Automotive Motor Två spindlar Automatisk BLDC borstlös yttre statorspole 2 stationer flygande gaffel lindningsmaskin

In summary, the versatility of the motor stator winding machine needs to be considered comprehensively from multiple dimensions such as equipment selection and design, mold and tooling design, winding process and quality control, and operation and maintenance. By taking these measures, it can be ensured that the winding machine can easily cope with different types of stators during the production process and maintain an efficient and stable operating state.

E-post: sales@vacuz.com