Professional motor production company, for brushless motor stator winding have their own requirements, especially for the way and requirements of the line, so what are the specific requirements of the brushless motor stator line? What are the advantages of winding machine and labor? The following Vacuz give you an introduction to it! I hope it can help you!

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

Generally speaking, the requirements for brushless motor stator winding and lining mainly include the following aspects:

1. Stator parameters: stator outer diameter, inner diameter, height, multi-wire winding, wire diameter and other parameters must meet the product requirements. Different motor stator parameters may lead to differences in winding difficulty, which in turn affects the quality of winding accuracy.

2. Winding method: The winding method should be as simple as possible, avoiding too complicated, in order to save enameled wire and ensure better winding effect. At the same time, according to the customer’s needs and stator parameters to choose the appropriate winding method.

3. Machine Configuration: For the stator with higher requirements on precision wire arrangement, the machine configuration needs to be more accurate, including servo motor driver, controller, guide rail, screws, coupling and other components.

4. Lining and mold device: these two parts are directly related to the quality of stator lining. The positioning must be accurate, the wiring must be stable, and the needle bar or flying fork part must meet the quality requirements. Mold processing must be careful, there should be no burrs or protrusions, polishing must meet the requirements.

5. Tensioner and auxiliary devices: tensioner tension should be set appropriately, neither too tight, nor too loose, to ensure the accuracy of the stator wiring. At the same time, the installation and placement of auxiliary devices such as wire wheel, wool felt and wire barrel must also meet the requirements.

Motor winding machine relative to manual winding, the advantages are mainly reflected in the following aspects:

1. Efficiency: the winding machine can realize automated production, significantly improve production efficiency.

2. High precision: winding machine winding precision is higher, can ensure the accuracy of the size and shape of the coil, thus improving the quality of the product.

3. Low cost: the winding machine can realize large-scale production and reduce production cost, which is conducive to the company’s cost control. The initial investment of pipe machinery and equipment may be high, but in the long run, its efficient production capacity can reduce the cost per unit of product.

5. Strong adaptability: the winding machine can be quickly replaced, the fixture is designed as an independent module, can be freely switched to universal products to adapt to changes in market demand.

6. Flexibility: The winding machine can be customized with different winding solutions or even special stator winding solutions to meet the diversified needs of the market.

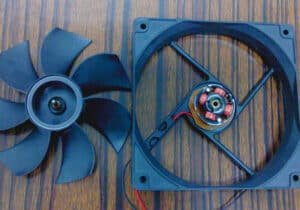

Cooling fan motor

What are the requirements for brushless motor stator winding? What are the advantages of winding machine and artificial than Vacuz above has made a brief account, I hope that this little knowledge can help you!

E-post: sales@vacuz.com