The winding process of brushless motor stator can’t be done without quality winding equipment, so where can you buy the right quality equipment? What is the difference between the winding machine and the different, Vacuz give you an introduction to it!

Motor Stator Automatic High Speed Inner Winding Machine(Six Stations)

Common winding machine has a needle-type internal winding machine and flying fork external winding machine two kinds of different products and parameters of the stator, the winding method and the choice of machine are different:

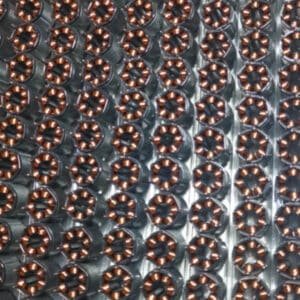

1. Needle-type internal winding machine, often for the core slot outward brushless stator, using needle winding method, moving up and down, or down and up with the line way, according to the stator parameters and wire diameter and winding needs, you can choose a different number of workstations and different configurations of the winding equipment.

2. Flying fork external winding machine, often for the core slot inward brushless stator, using flying fork winding method, flying fork high-speed rotation with wire way, according to the stator parameters and wire diameter and winding needs, can choose different number of stations and different configurations of the winding equipment.

High Speed Four Spindles Cooling Fan Motor Automatic BLDC Brushless Inner Stator Coil Needle Winding Machine

Whether it is a needle-type winding machine or flying fork winding machine, need to rely on the configuration, technology and strength of the manufacturer, most manufacturers are now distributed in the Pearl River Delta and the Yangtze River Delta area, different winding machine manufacturers, the strength of the difference, but also no lack of some intermediaries in the inside, in any case, it is recommended that the selection of the winding machine equipment, more than one comparison, the field to see the factory, see the machine operation, to ensure that the configuration and machine Stability are in line with production requirements, so that the work can achieve twice the result with half the effort!

WhatsApp/Wechat: +86 13075286997

E-post: sales@vacuz.com