Motor stator winding machines will show significant differences when winding different types of wires. These differences are mainly reflected in wire diameter and cross-sectional area, current carrying capacity, winding difficulty and speed, equipment requirements and application scenarios. Vacuz will analyze in detail the differences between motor stator winding machines in winding thin wires and thick wires, as well as single wires and multi-wires. I hope it can help everyone!

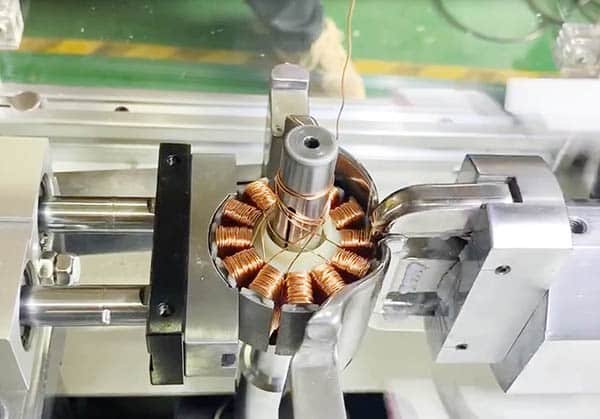

Lindning av borstlös motor

1. The difference between thin lines and thick lines

1. Wire diameter and cross-sectional area

Thin wires have a smaller wire diameter and a correspondingly smaller cross-sectional area; thick wires have a larger wire diameter and a correspondingly larger cross-sectional area. This difference directly affects the current carrying capacity and physical properties of the wire.

2.Current carrying capacity

Due to the difference in cross-sectional area, the current carrying capacity of thin wires is relatively weak, while the current carrying capacity of thick wires is relatively strong. Therefore, thick wires are usually chosen where larger currents need to be carried.

3. Winding difficulty and speed

Thin wire has a small diameter and a relatively fast winding speed, but it is easy to break and requires higher tension control accuracy. The thick wire has a large diameter, and the winding speed must be slowed down to avoid damaging the wire. At the same time, it is necessary to ensure that the leakage value reaches the standard. This increases the difficulty and cost of winding thick wires.

4. Equipment requirements

Thin wires have relatively low requirements for equipment, but high precision requirements for tensioners and auxiliary parts to ensure the stability of the wire during the winding process. Thick wires have higher requirements on equipment, requiring a more stable winding environment and higher equipment accuracy to ensure winding quality.

5. Application scenarios

Thin wires are often used in low-power motors or motors that require high speeds because their smaller wire diameter and cross-sectional area help reduce the size and weight of the motor. Thick wires are often used in high-power motors or situations that need to carry larger currents to meet the motor’s current carrying capacity requirements.

2. The difference between single line and multi-line

1. Current transmission

The single-wire current transmission method is simple. The current flows from the power line through the motor and returns to the power supply. It is suitable for motors that only need to rotate in one direction. Multi-wire (such as double wire) returns the current to the power supply through additional wires, which can change the direction of motor rotation, increasing the flexibility and application scenarios of the motor.

2. Winding method

The single wire winding process is relatively simple, and only the direction and tension of the single wire need to be considered. The multi-wire winding process is more complicated, and issues such as parallel winding of multiple wires, tension balance, and notch distance need to be considered to ensure winding quality and motor performance.

3. Equipment requirements

Single wire has relatively low equipment requirements and is suitable for simple winding tasks. Multi-wires have higher requirements on equipment, requiring more precise spare parts and a more stable winding environment to ensure winding quality and motor performance stability.

4. Application scenarios

Single wire is suitable for low-power, one-way rotating motors, such as motors in household appliances such as fans and mixers. Multi-wire is suitable for motors that need to change the direction of rotation, carry larger currents, or require higher accuracy, such as motors in high-performance equipment such as automobile engines and industrial robots.

Aero Brushless Motor Stator

In summary, there are significant differences between motor stator winding machines for winding thin wires and thick wires, as well as single wires and multi-wires. In practical applications, it is necessary to select the appropriate winding method and equipment configuration based on the motor’s power, rotation direction, current carrying capacity and other factors. This can not only improve the performance and stability of the motor, but also reduce production and maintenance costs, creating greater economic benefits for the enterprise.

E-post: sales@vacuz.com