Rotor assembly line belongs to non-standard equipment, consists of many individual machines and components, in the operation process, it is inevitable that some small problems will arise, affecting the rhythm of the operation of the entire line, so how to do with the failure of the rotor assembly line? How to quickly solve it? What is a good way, Vacuz give you an introduction to it!

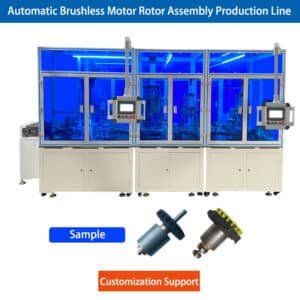

Motor Production Line

When a rotor assembly line malfunction, here are some suggested steps to solve the problem quickly:

1. Try to determine the general scope of the problem, such as whether it is an electrical, mechanical or software problem.

2. Check the power, air and hydraulic sources:

Check that the power supply is stable and that the voltage is within normal limits. Check if the air supply is normal and the air pressure is stable. Check whether the hydraulic source is working properly and whether the hydraulic oil is sufficient and clean.

3. Check the sensor and fixture:

After long term operation, the sensors and fixtures may shift in position or decrease in sensitivity. Check these parts carefully to make sure they are in the correct position and function properly.

4. Check relays, flow control valves and pressure control valves:

Relays may have grounding problems and need to be inspected and replaced. Flow control valves and pressure control valves may be loose or slipping due to vibration and need to be inspected and adjusted.

5. Check electrical, pneumatic and hydraulic circuit connections:

Check the state of the electrical circuit to make sure there are no short-circuit problems. Check whether the pneumatic and hydraulic oil pipes are damaged or clogged, and replace or clean them in time.

6. Carry out targeted inspection according to the failure phenomenon:

If excessive vibration or abnormal noise occurs in the production line, it may be due to rotor imbalance or bearing problems. If the bearings are excessively worn or poorly installed, they need to be replaced or repaired in time. If there are problems such as winding grounding or core corrosion, appropriate repair measures need to be taken.

7. Quick response and emergency handling:

Once the fault is found, the production line should be stopped immediately to prevent the fault from expanding or causing greater damage. According to the fault, timely notify the relevant maintenance personnel or manufacturers of technical support personnel to deal with.

8. Record and summarize experience:

After the fault is solved, detailed records should be made of the fault phenomenon, processing methods and processing results. Summarize the experience and analyze the cause of the failure in order to avoid similar problems in future production.

9. Precautions.

Regularly maintain and repair the production line to ensure that the equipment is in good working condition. Strengthen staff training to improve staff’s proficiency in equipment operation and maintenance. Establish a perfect failure warning and emergency plan mechanism, so that when a failure occurs, it can be quickly responded to and dealt with.

Automatisk produktionslinje för montering av borstlös motorrotor

What should we do if the rotor assembly line fails? How to quickly solve the problem?Vacuz above has made a brief account, I hope these tips can help you!

E-post: sales@vacuz.com