Automatic Toroidal Coil Inductor Winding Machine. Unlike Multi-axis winding machines, the fixture and base consist of three parts. Different inner diameters can be created . The jig also has a corresponding clamping range for different number of turns.

In general, there are several wear parts on a ring winder that need to be replaced frequently.

1. The wire storage ring, also known as the steel ring, is one of the important parts to complete the storage and winding; its quality directly affects the service life of the product. Indirect cost and quality of the winding products.

2. Support wheel, also known as guide wheel, the number of different, its material is directly related to its service life.

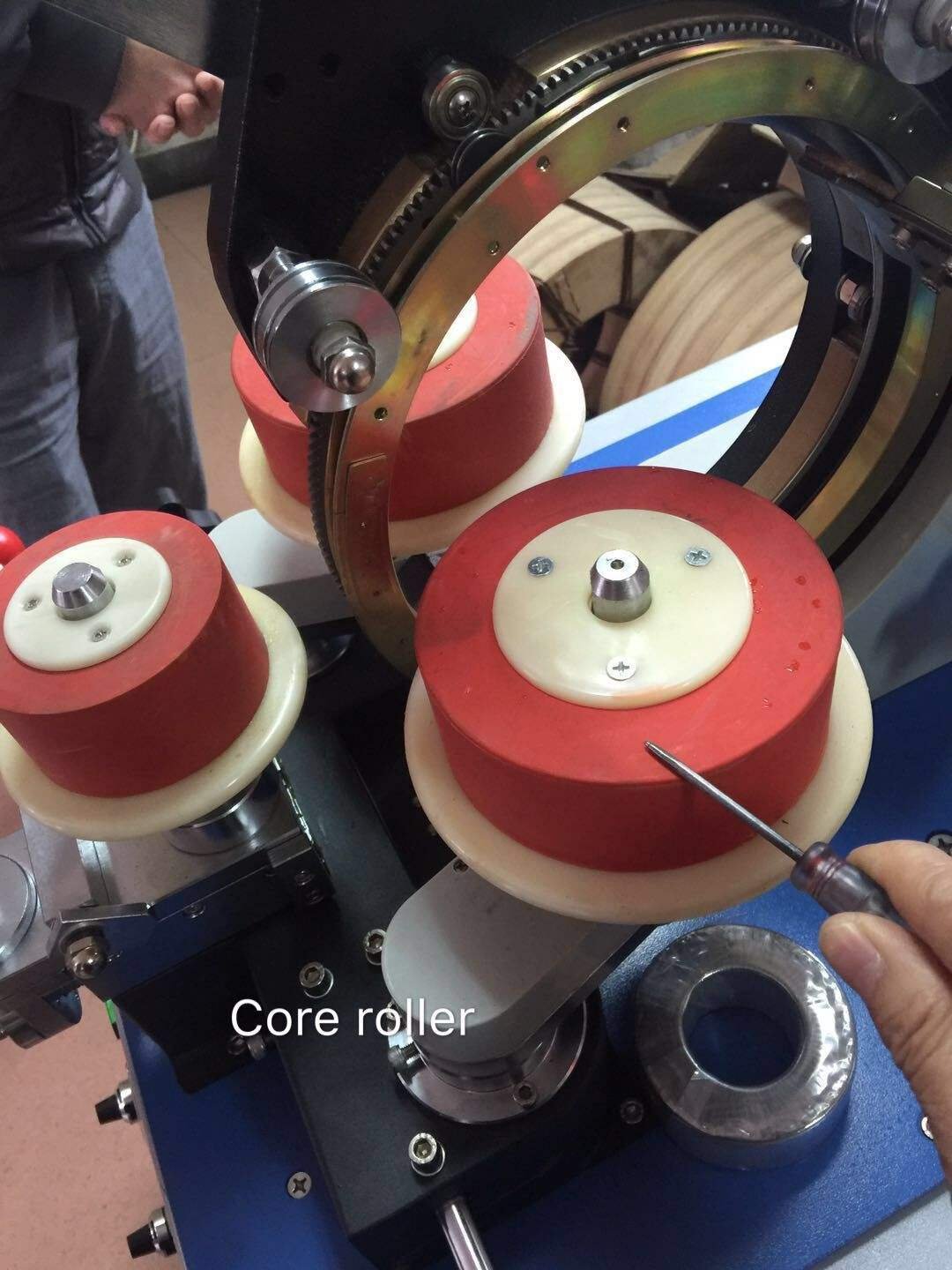

3. The service life of the jig roller and the wire diameter of the winding product. Size and material are related.

4. Belt. Side slide rail and other consumable parts.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]