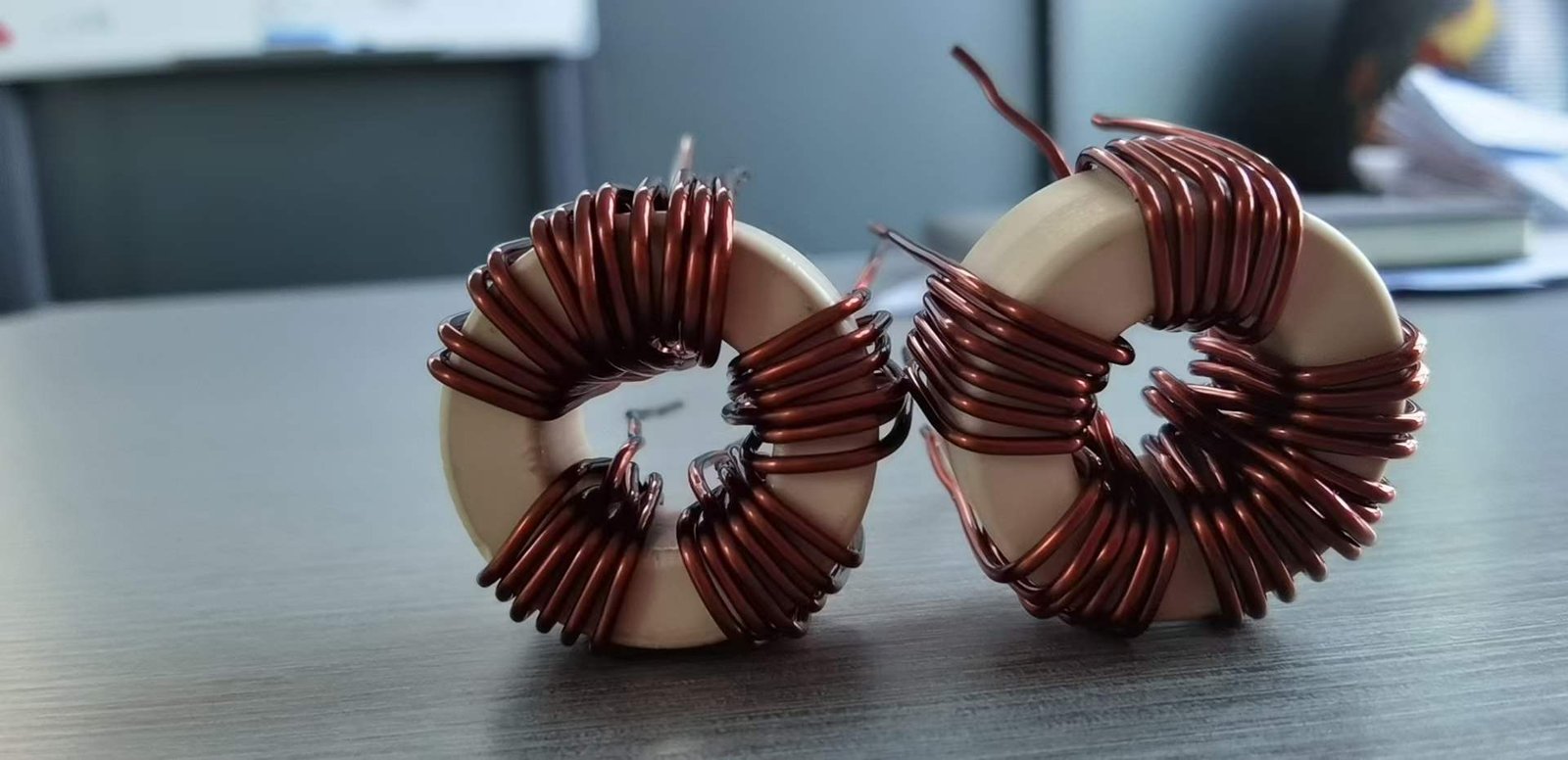

1, the coil winding machine motor overheating causes analysis and treatment

In normal operation, the motor overheating causes are the following: too high or too low voltage, overload, insufficient cooling air, motor failure itself.

The overheating of the winding motor due to high or low power supply voltage rarely occurs, while the motor itself is overheated due to fault, the motor can be checked and judged by the change in operating current and motor protection devices. Motor overheating due to insufficient cooling air is a common cause of Z. Wire-wound motor cooling air is generated by the fan mounted on the motor shaft as the motor rotates, and blows to the motor winding through the air duct at the top of the motor housing, so as to achieve the purpose of cooling the motor. Due to the relatively large dust at the production site of slag powder, the air ducts are easily blocked after years of operation. Therefore, the winding machine ventilation channel should be flushed and cleaned regularly.

2, collector ring burned and brush jump spark

The main difference between the winding machine and squirrel cage motor is that the three end lines of the rotor winding of the winding machine are connected to three copper or steel slip rings mounted on the rotor shaft, which are connected to the external circuit through the brushes. This unique structure of the winding machine leads to a tendency for the collector ring to burn out and the brushes to spark. Generally speaking, the reasons for this situation are: the brush and the collector ring are not well ground, the brush cannot fully contact the surface of the collector ring, the brush and the brush box are not well matched (too loose or too tight), the brush pressure is not suitable, the number of brushes is not reasonable, the collector ring is oval, etc.

If there are brushes and collector ring surface contact area of less than 70%, the brush with better contact surface flow through the electric flow, more heat, easy to appear brush braid burned, thus further aggravating the load of other brushes, serious will burn the whole phase brush and damage the slip ring. Therefore, during the daily maintenance of the winding machine, special attention should be paid to the brush and collector ring contact area is intact. When using different production batches of brushes, it may cause brush and collector ring damage due to the difference of brush composition ratio, so the same production batch should be used as much as possible when replacing brushes.

In addition, when the brush and brush box with too loose, easy to cause the brush in the brush box jumping and spark; too tight, the brush in the brush box activity is too small, easy to jam and lead to collector ring overheating damage. When the brush pressure is small, the brush is easy to jump and spark; when the pressure is too big, the brush and the collector ring friction increases, easy to overheat and lead to collector ring damage.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]