Automatic BLDC motor stator coil winding machine: China’s current stage of the level of winding machine! Vacuz machinery and equipment below to tell you about it!

First, the outer slot winding machine. There are many kinds of winding machine, stator winding machine. Electric fan winding machine is an old technology, so the price is cheap. Before the emergence of electric fan winding machine, single controller has a lot of double position. Currently, dual-controller dual, single-controller quad, and single-controller six servo winders are being developed. There are also four winding machines that rotate 180 degrees. There are now more servo motors with increased scissors and tension. In addition, the molds are equipped with precision wiring molds with springs. Another is adding shafts, thin shafts. The team is neater. The overall level has improved significantly. The appearance of the winding products has been improved.

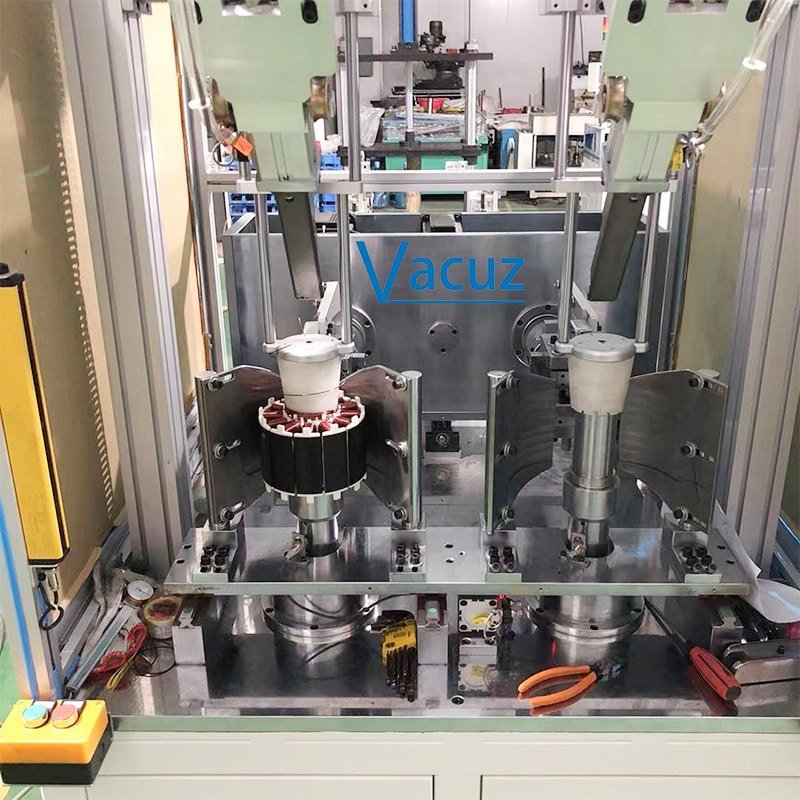

Second, the internal winding machine is a kind of stator winding machine with internal groove. The inner winding machine is divided into single head inner winding machine, double head inner winding machine, four inner winding machines and six inner winding machines. The main winding machines are servo cam-driven winders, wire-driven winders, and conveyor belt winders. The older, fully cammed turbines have been eliminated. Several types of winding machines have their own advantages, and the main speed is the cam servo winder. Fast winding speed for small thickness products. Do not change molds for long periods of time. If the stator thickness is high, a wire rod drive is used, which is easy to adjust to the height of the product. But very slow. There is another one. Belt drive. In principle, the belt drive does not comply with the design principles. No amount of side door belts will last long. Belts need to be replaced often. The above winder has grown rapidly in about 3 years. This technology sells very well. But there are too many servo motors and the cost is too high.

Third, transformer winding machine, transformer winding machine used to be a single axis, now there are 2-axis, 4-axis, 6-axis, 8-axis and 12-axis winding. In addition, there are additional coils wrapped in rubber paper. Automatic disconnection. The fifth and more advanced is the magnetic ring winding machine. The average person cannot understand how this machine works. A few years ago it was expensive. The current price is reasonable. Many people have changed their minds. Sixth, the vertical winding machine, which winds the coils step by step, directly onto the wire cups, in conjunction with the winding machine. Efficiency has been increased by one step. This kind of winding machine is too expensive, small factories can not afford. Seventh, rotor winding machine, single flying fork winding machine, double flying fork winding machine, and now there are double flying fork four-station winding machine. With the production line, equipped with fully automatic double toggle fork production line. The equipment is automated.

Overall, sales have been growing over the years. But nothing revolutionary has happened. There is no jump in the upgrading process.2. In general China is in the middle of the international level. Compared to the United States and Japan. We are still a little far. The power of innovation still needs state support. SMEs want to innovate, but if they want to, they can do it.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]