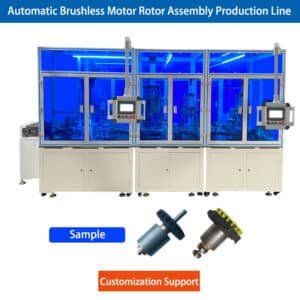

With the rapid development of brushless motor industry, many manufacturers are beginning to popular automatic equipment assembly mode, such as the production of brushless motor rotor, the use of automated production lines, but in the assembly, may also encounter a variety of trouble, resulting in operational failure or not smooth, so how to troubleshoot and solve the failure?

1. Check all power supply, air source and hydraulic equipment

Generally speaking, the rotor automatic assembly line failure, a large part of the reason from these places, assembly is completed, carefully check the line of equipment, including the power supply situation, air pressure device and hydraulic pump situation.

2. Rotor automatic assembly line sensor location determination

Very often, after the line has been in operation for a period of time, some sensors may change, malfunction, weaken sensitivity and other situations. Pay attention to check these places, check the sensitivity and location is correct, if there is a problem, timely adjustment or replacement. In is the line body in operation, there may be some vibration, resulting in the sensor loose, be sure to double-check to determine the normal, firm situation.

3. Relays, flow control valves and pressure control valves

Relays are similar to magnetic induction sensors, be careful to check. Rotor assembly line of the pneumatic or hydraulic system, throttle valve opening and pressure valve pressure adjustment spring, due to assembly line vibration easily caused by loose, need frequent maintenance.

4. Electrical, pneumatic and hydraulic circuit connection check

Check the circuit status of the equipment for disconnection problems. Check whether the branch air pipe is broken. Check whether the hydraulic oil pipe is clogged, and the air pipe should be replaced in time if there is a breakage, and the hydraulic oil pipe should be replaced in time if there is a problem.

5. Generally speaking, the probability of program problems with the controller of the rotor automatic line is still relatively low, but if problems arise, professional technicians are needed to handle them.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]