For brushless motor production, the stator and rotor is a relatively core part, the previous manual way of assembly, low efficiency, now most of the stator production line and rotor production line mode assembly and processing, an automatic line to save most of the labor, efficiency has increased significantly, the assembly effect is also better. So what is the process of brushless motor stator and rotor production line, Vacuz briefly introduce it to you!

1. Brushless motor stator production line process.

Collar material – insert insulating paper – install end plate – winding – slot wedge – paint stripping – welding public end – tying – stator comprehensive test – dipping paint – grinding outer circle – packaging – storage.

Insulating paper insertion is commonly used in slot paper machine equipment, wire winding is commonly used in flying fork winding machine or needle internal winding machine equipment, slot wedge is used in slot wedge machine, and paint stripping is commonly used in paint stripping machine equipment.

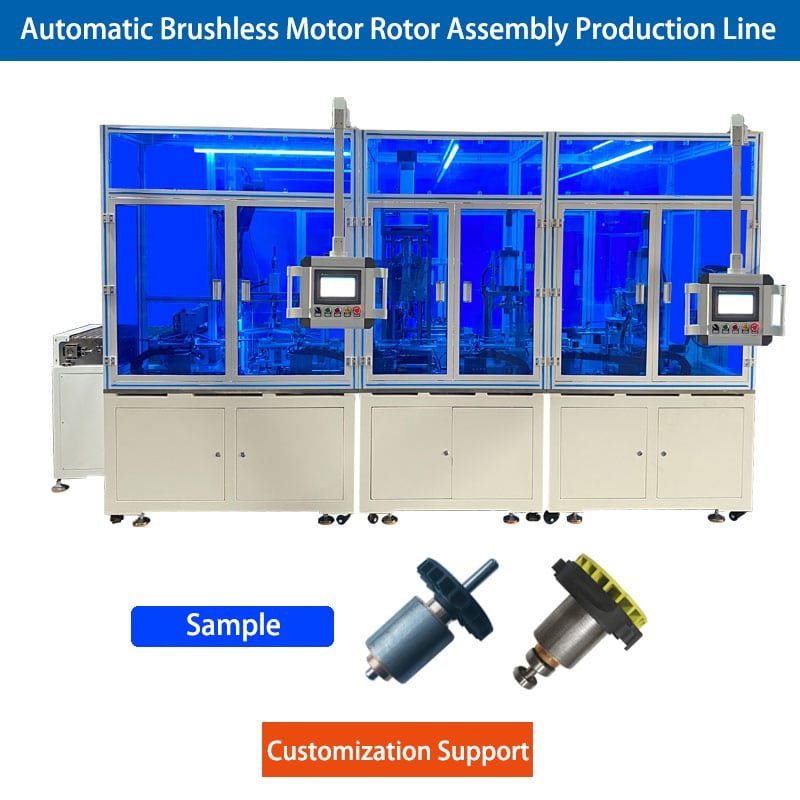

2. Brushless motor rotor production line process.

Collar material – paste magnet – magnet pressed – automatic gluing – rotor testing – packaging – storage.

The magnet machine is commonly used to paste the magnets, the magnet press is commonly used to press the magnets, and the automatic gluing machine is commonly used to glue the magnets.

Yukarıdakiler fırçasız motor stator ve rotor üretim hattı sürecidir, sayısız motorun üretimi sıkı süreçlerdir, sadece doğru üretim yöntemine uygun olarak, bitmiş ürünün kalite gereksinimlerini karşıladığından emin olmak için sürekli test ve denetim.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]