For brushless motor manufacturers, fully automatic stator winding machines are indispensable. A thorough evaluation of the cost-effectiveness and durability of these machines, including usage experience, is crucial to ensure normal production and company profitability. So how are the cost-effectiveness and durability of a winding machine determined? What are the evaluation criteria and usage experience? Below, Vacuz will provide a brief introduction!

I. Methods for Determining Cost-Effectiveness

1. Clarify Production Needs

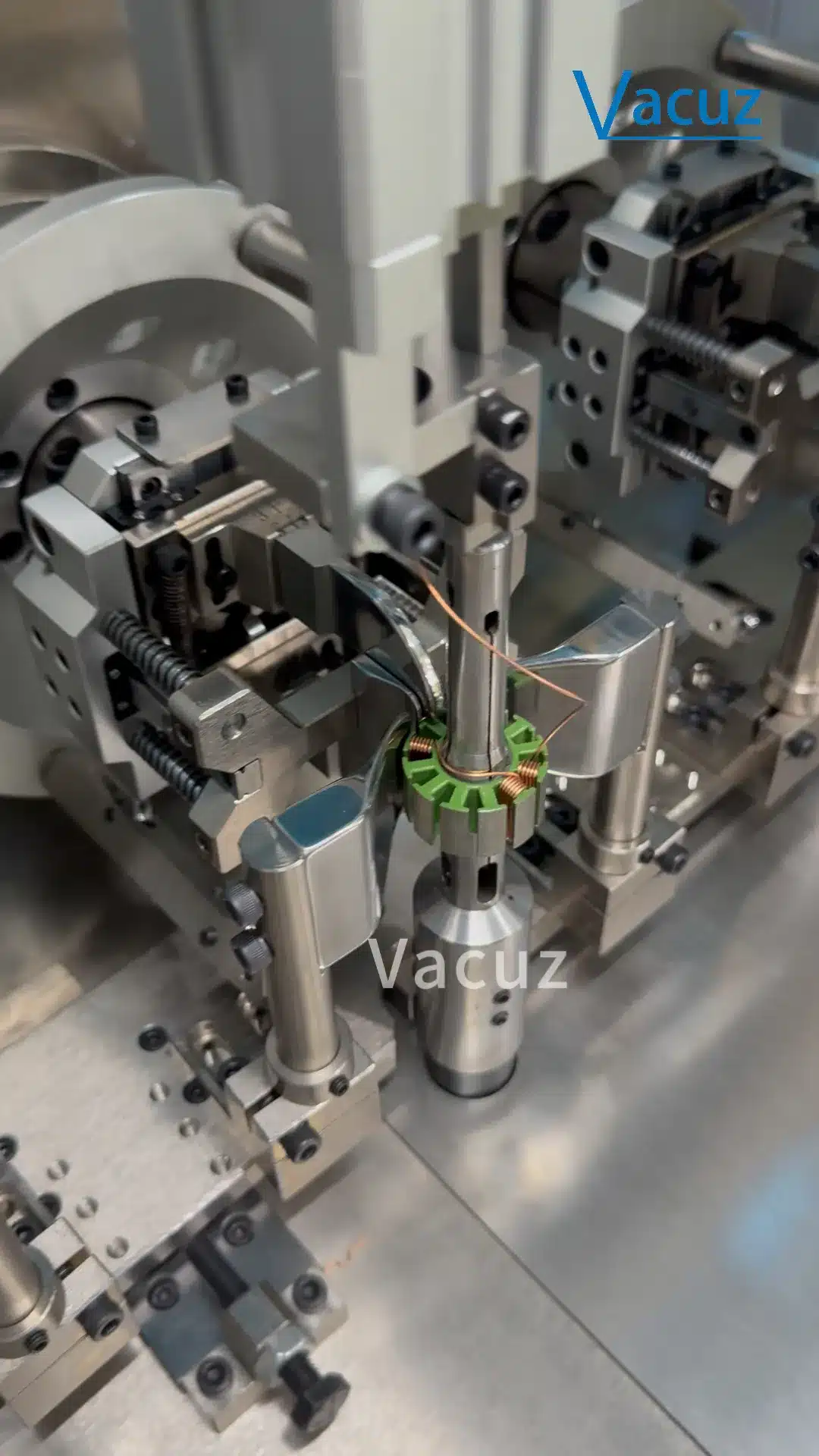

Specification Matching: Based on stator dimensions (outer diameter, inner diameter, stack thickness), number of slots, wire diameter, and other parameters, select a suitable winding machine model. For example, high-stack-thickness stators require equipment with strong tension control capabilities, and multi-slot stators require a high-precision wire laying system.

Efficiency Requirements: Select the number of workstations (single-axis or multi-axis) based on production volume requirements. Multi-axis equipment can process multiple stators simultaneously, but the cost is higher; a balance must be struck between efficiency and budget.

Functional Requirements: If producing multiple specifications, select equipment that supports quick changeover and adjustable parameters; if high-precision winding is required, select a model equipped with a laser rangefinder and a high-precision servo system. 2. Comparing Core Configurations

Key Components: The quality of components such as servo motors, lead screws, and guide rails directly affects equipment stability and lifespan. Prioritize branded components.

Control System: PLC or industrial computer-controlled equipment can perform complex logic operations, but is more expensive. For simpler products, a basic control system can reduce costs.

Additional Functions: Automatic counting, fault diagnosis, and remote monitoring can improve efficiency but increase costs. Choose based on actual needs, avoiding paying for unnecessary features.

3. Evaluating Price and Value

Brand Premium: Choose products with mature technology and comprehensive after-sales service, suitable for companies with high stability requirements, such as Vacuz winding machines. Ordinary brands are cheaper, but quality needs careful evaluation.

Economies of Scale: For mass production, standardized equipment is preferable at lower costs. For small-batch or customized needs, choose manufacturers that support non-standard customization; although more expensive, they can meet specific requirements.

Long-Term Costs: Consider equipment lifespan, maintenance costs, and energy consumption. For example, low-noise, low-energy equipment can reduce operating costs and improve cost-effectiveness.

II. Durability Assessment Points

1. Materials and Craftsmanship

* **Body Material:** High-quality equipment uses a high-strength alloy or cast iron body, offering strong shock resistance and resistance to deformation over long-term use.

* **Surface Treatment:** Rust-proof coatings or electroplating extend the equipment’s lifespan, making it particularly suitable for humid or corrosive environments.

* **Machining Precision:** High-precision machining ensures tight fit between components, reducing wear and improving stability.

2. **Core Component Quality:**

* **Servo Motor:** Selecting brand-name motors ensures high torque, fast response, and stability during high-speed winding.

* **Lead Screw and Guide Rail:** High-precision ball screws and linear guide rails reduce motion friction, improve wire routing accuracy, and extend service life.

* **Tension System:** High-precision tension sensors (error ≤ ±0.1%FS) and PID algorithms adjust tension in real time, preventing wire breakage or slack and protecting the equipment.

3. **Heat Dissipation and Protection Design:**

* **Heat Dissipation System:** High-efficiency cooling fans or water-cooling systems prevent overheating of electronic components, reducing the failure rate.

Protection Rating: Equipment with an IP54 or higher protection rating is dustproof and waterproof, suitable for harsh production environments.

Vibration Damping Measures: Vibration damping tables or rubber damping pads reduce the impact of vibration on winding accuracy and protect the equipment structure.

III. Usage Experience and Maintenance Recommendations

1. Çalışma Prosedürleri

Parameter Settings: Adjust the tensioner range according to wire diameter, winding speed, etc., to avoid thin wire breakage or thick wire loosening. For example, set the tension for 0.1mm copper wire to 0.5-1.2N.

Die Installation: Use a laser rangefinder to calibrate the die installation position, ensuring the first turn positioning error is ≤0.01mm to reduce wire overlap.

Environmental Control: Maintain the workshop temperature at 20-30℃ and humidity ≤60% to prevent electronic components from getting damp or overheating.

2. Daily Maintenance

Cleaning and Lubrication: Regularly clean dust from the equipment surface and add lubricating oil (such as guide rail oil or gear oil) to reduce wear.

Tension Monitoring: Install a tension sensor to provide real-time feedback of the tension value; automatically stop and alarm in case of abnormality.

Vibration Analysis: Monitor equipment vibration frequency using accelerometers to detect potential faults early (such as bearing wear).

3. Troubleshooting

Wire Breakage: Check if tension settings are reasonable, wire diameter matches slot opening, and if the die is worn.

Uneven Wire Laying: Adjust the wire guide tension to ensure proper distance between the guide and the bobbin.

System Failure: Regularly back up the program, record fault codes, and optimize process parameters through big data analysis.

4. Upgrades and Modifications

Technical Upgrades: Upgrade the control system according to production needs to improve intelligence.

Component Replacement: Regularly replace wear parts (such as belts and bearings) to avoid machine downtime due to small component failures.

Function Expansion: Add automatic detection modules (such as resistance testing and insulation withstand voltage testing) to improve product quality.

How to determine the cost-effectiveness and durability of a fully automatic stator winding machine? What are the evaluation and usage experiences? Vacuz has provided a simple explanation above; we hope this information is helpful!