Stator winding machines and rotor winding machines for brushless motors can be distinguished by their applicable objects, winding methods, equipment structure, performance parameters, and application scenarios. Each has its advantages in terms of automation, production efficiency, winding accuracy, equipment flexibility, and operational stability. Below, Vacuz will give you a brief introduction!

I. Differentiation Methods

1. Applicable Objects:

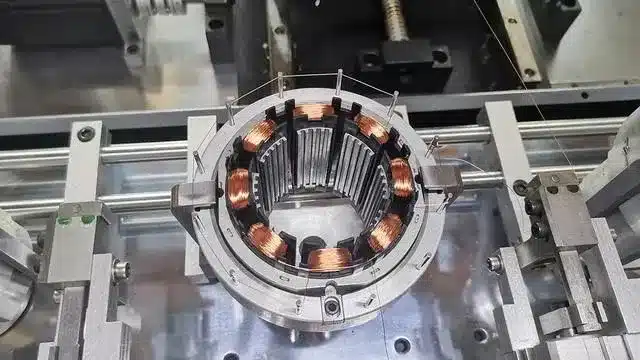

Stator Winding Machine: Specifically used for winding the stator of a brushless motor. The stator is the stationary part of the motor, usually located on the outside or periphery of the motor, and consists of an iron core, windings, and a frame.

Rotor Winding Machine: Specifically used for winding the rotor of a brushless motor. The rotor is the moving part of the motor, usually located inside the stator, and consists of an iron core, a shaft, and bearings.

2. Winding Methods:

Stator Winding Machine: Different winding methods are used depending on the direction of the stator slots. For example, brushless motor stators with outward-facing slots are often wound using a fly fork winding machine; brushless motor stators with inward-facing slots are mostly wound using a pin-type internal winding machine.

Rotor winding machine: Typically uses a fly fork winding method, capable of double fly fork winding, cross winding, etc., with a relatively simple winding method. However, the specific winding method may vary depending on the motor type and design requirements.

3. Equipment Structure:

Stator winding machine: The structure is relatively complex, needing to adapt to different slot orientations and stator sizes. For example, a pin-type internal winding machine requires a precision pin-type winding head to achieve internal winding.

Rotor winding machine: The structure is relatively simple, mainly focusing on winding speed and winding quality. For example, a fly fork winding machine uses a high-speed rotating fly fork to wind the wire onto the rotor core.

4. Performance Parameters:

Stator winding machine: Winding speed varies depending on the equipment type and stator parameters. For example, the winding speed of a fly fork winding machine can reach over 2600 r/min, and some even reach 5000 r/min; while the speed of a needle-type internal winding machine is relatively slower, reaching 800-1200 r/min.

Rotor winding machines: The winding speed is also relatively fast, but the specific value varies depending on the equipment model and rotor parameters. Generally speaking, the winding speed of rotor winding machines can meet the needs of mass production.

5. Application Scenarios:

Stator winding machines: Widely used in aerospace, model aircraft/drones, agricultural drones, new energy vehicles, home appliances, water pumps, power tools, cooling fans, etc.

Rotor winding machines: Also used in the above fields, but more focused on motor products requiring high-speed rotation, such as model aircraft, fascia guns, cooling fans, etc.

II. Features and Advantages

1. Features and Advantages of Stator Winding Machines:

High Automation: Achieves integrated operation of manual loading and unloading with automatic clamping, winding, wire arrangement, and wire cutting, greatly improving work efficiency.

Precision Winding: Employing precision mechanics and a servo drive system ensures stable and reliable winding quality with a high slot fill rate.

Multi-Station Design: Supports single to six-station configurations, suitable for mass production and improving efficiency.

Intelligent Operation: Equipped with a PLC and touch interface, it provides real-time monitoring of winding parameters, making operation simple and convenient.

Modular Design: Modular fixture design allows for quick changeovers, reducing mold costs and downtime.

2. Features and Advantages of the Rotor Winding Machine:

High-Speed Winding: Utilizes a high-speed rotating fork or similar mechanism for rapid winding, improving production efficiency.

Robust and Durable Structure: The overall frame combines the advantages of sheet metal and aluminum profiles, providing excellent shock absorption and stability.

Flexible Fixture Design: The modular fixture design ensures fixed and accurate positioning, easy replacement, and rapid adaptation to the production needs of various product models.

Accurate and Flexible Control: The equipment is equipped with an advanced servo motor control system and an intuitive human-machine interface, allowing users to freely set parameters according to actual needs.

Smooth and stable operation: The use of high-quality components such as precision guide rails, lead screws, cylinders, and tensioners ensures smooth machine operation and appropriate wire tension.

How to distinguish between brushless motor stators and rotors in a winding machine? What are their characteristics and advantages? Vacuz has provided a simple explanation above; we hope this information is helpful!