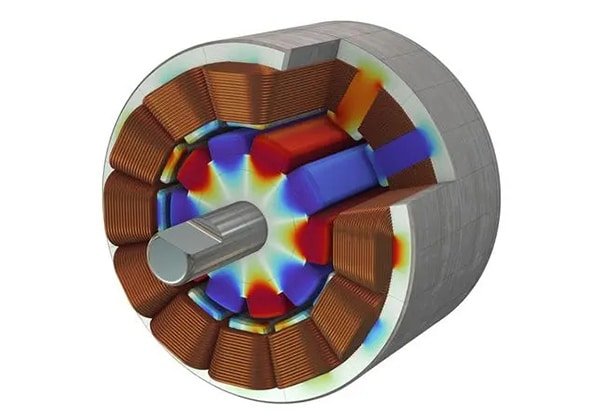

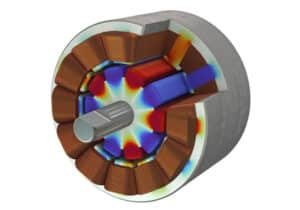

The application of permanent magnet motor is more and more widely, not only good performance, but also gives convenience to our life, and is favored by the majority of customers.

The assembly process of permanent magnet motor rotor is very important, many friends ask, is it difficult to assemble the permanent magnet motor rotor? Vacuz gives you an introduction to it!

Because the permanent magnet rotor dramatically strong magnetism, so the rotor is loaded into the stator has some difficulties in the work. If you do not take the right measures, the rotor once touched the stator core, the two will be tightly sucked together, it is difficult to move forward. When using manual operation, sometimes it is easy to pinch the hand because of the attraction and fast approach squeeze. In addition, when assembling, you should not wear a watch or cell phone to operate at close range to avoid damage by its magnetization.

For smaller permanent magnet motors, the rotor can be manually mounted in the stator, but safety precautions should be taken. For larger permanent magnet motors, special equipment must be used for this work.

1、The place where the motor parts are assembled and placed must be kept clean, especially without ferromagnetic substances.

2、Assemble the parts such as an end cap without wave spring in the bearing chamber to the machine base, and then put it on the trolley of the special equipment, and fix it with the trolley by pressing the plate. Then adjust the height of the trolley so that the axis of the frame reaches the axis of the top bar of the equipment.

3.Put the outer bearing cover which fits with the end cover on the fixed top bar. Then translate the trolley so that the base is set on the fixed top bar. At this time, it is necessary to further adjust the height of the trolley so that the axis of the carriage and the axis of the equipment top bar are really or nearly coincident.

4, the two ends of the bearing inner cover into the rotor shaft, after the two ends of the bearing set to the bearing seat position. For open type bearings, add enough grease as needed.

5、Assemble the end cap of the other end with the bearing at that end (if there are parts such as wave springs, they should also be placed in the intended position) and install the bearing cap.

6、Lift the whole rotor with one end cover and put it between two top bars, move the movable top bar, and use the top hole of the rotor shaft to erect the rotor.

7、Move the trolley horizontally, drive the stator to reach the axial position with the rotor assembly and stop. In this process, carefully observe the overlap between the frame axis and the equipment top bar axis, and further adjust if necessary. After that, install the end cover, bearing outer cover, retaining ring, etc. at both ends.

8、Exit the movable top bar. Turn the rotation axis by hand. If it is flexible, the installation is complete.

The above is the assembly process of permanent magnet motor rotor, the difficulty is certainly there, but we should pay attention to master the correct method of assembly, otherwise it is easy to have various problems.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]