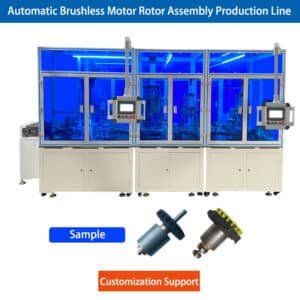

Fan motors are now commonly used brushless motors, assembly were previously used in manual mode, with the emergence of automatic assembly lines, production has become less complex. For fan motor outer rotor, how to assemble it specifically? What are the advantages?

Wind turbine motor rotor assembly process.

Automatic stator winding – terminal insertion – butt welding and stator performance testing – stator insertion into bearing housing – shaft insertion – shaft runout – glue application – magnetic strip expansion – drying – magnetizing – stator and rotor assembly, etc.

Advantages of wind turbine motor rotor assembly line.

1. unmanned production of the rotor section is possible.

2. stable production and easy operation and debugging.

3. whole process data acquisition, monitoring and storage.

4. important parts have testing equipment.

5. Customized according to customer’s process, good product consistency and stable quality.

6. Non-standard customization is possible.

Vacuz brushless motor equipment is developed and customized according to customer needs. It is highly versatile, in line with the human-machine functional characteristics, easy to operate and maintain manually, and suitable for most small and medium-sized brushless motor products.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]