Among the many brushless motor winding machine manufacturers, it is not easy to select a truly high-quality manufacturer. These manufacturers not only excel in product quality and performance, but also have significant advantages in after-sales service and technical support. The following is a detailed analysis of these advantages and how to identify the performance of winding machines by Vacuz. I hope it can help everyone!

Key points for selecting high-quality brushless motor winding machine manufacturers:

1. Leading technical strength:

With advanced technical strength and process level, we are able to create high-precision, high-efficiency and stable winding machines.

We focus on optimizing product design and continuously improve the adaptability and flexibility of equipment to meet the diverse needs of customers.

2. Strict quality control process:

From the procurement of raw materials to the delivery of finished products, these manufacturers follow strict quality control processes.

Each process is carefully inspected and tested to ensure that the equipment can maintain excellent performance and reliable quality during long-term use.

3. Thoughtful after-sales service system:

They provide comprehensive after-sales services, covering equipment installation and commissioning, maintenance, technical training and other aspects.

The professional after-sales service team is on call at all times to quickly respond to customers’ inquiries and complaints, ensuring that customers receive timely and effective support during use.

4.Strong technical R&D support:

These manufacturers have professional technical R&D teams and can provide customized solutions based on customer needs.

Continuous innovation and research and development will promote the development of winding machine products in a more advanced and efficient direction.

5. Diversified product lines:

We provide winding machine products of various models and specifications to meet the personalized needs of different customers.

Provide non-standard customization services to ensure that the equipment can be perfectly integrated into the customer’s production environment.

How to identify the performance of winding machines:

1. Appearance and configuration inspection:

First, check that the device is in good condition and has no obvious flaws.

Secondly, it is necessary to confirm whether the equipment configuration is complete and whether key components such as servo motors, lead screws, guide rails, etc. meet the specification requirements.

2. No-load running test:

After the equipment is installed and debugged, a no-load operation test is performed. Observe whether the equipment runs smoothly and whether the speed meets the standard.

At the same time, check whether the bearings and moving parts are overheated or make abnormal sounds.

3. Line testing and accuracy assessment:

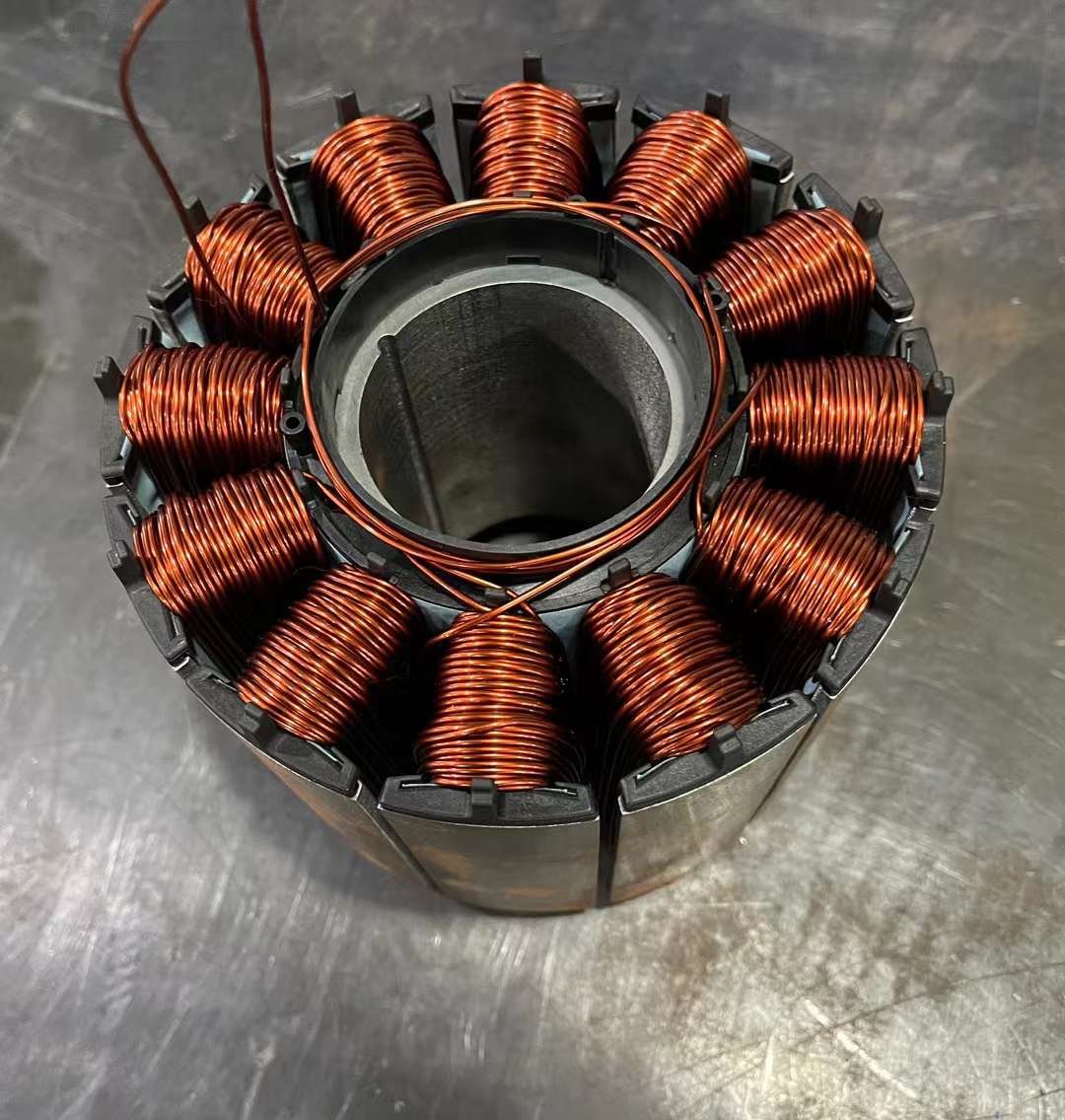

Conduct line tests to observe whether the number of windings is accurate during the winding process and whether the wiring device operates smoothly and correctly.

Check whether the winding coil is neat and compact, and whether the insulation layer of the enameled wire is intact. In addition, the winding accuracy and production efficiency of the equipment must also be evaluated.

4. Intelligence and reliability considerations:

It is necessary to confirm whether the equipment is equipped with intelligent control systems and sensors to achieve automated and intelligent operation and management.

At the same time, it is necessary to evaluate the reliability of the equipment, including the stability of the mechanical structure and electrical system, as well as the failure rate and maintenance cost in long-term operation.

5. Noise and versatility assessment:

Observe the noise level of the equipment during operation. Low noise usually means that the equipment has a compact structure and runs smoothly.

In addition, it is also necessary to check the versatility of the equipment, whether it is suitable for various models of brushless motor products, and whether it supports non-standard customization.

6. After-sales service and technical support survey:

Understand the equipment manufacturer’s after-sales service policy and technical support capabilities. Including equipment warranty period, maintenance response time, and whether equipment operation training and technical support are provided.

To sum up, choosing a high-quality brushless motor winding machine manufacturer and identifying the performance of the winding machine requires comprehensive consideration of multiple aspects. Through careful comparison and evaluation, you can select high-quality winding machine products that suit your needs.

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]