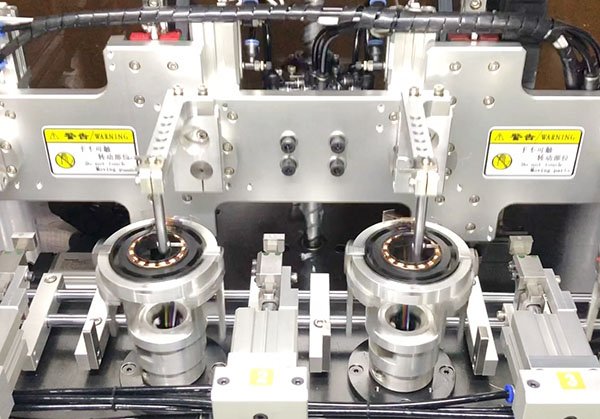

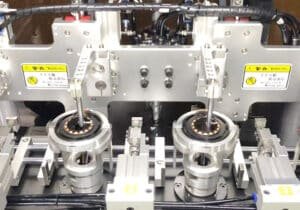

1、Winding machine spindle mechanism

The winding machine is driven by a three-phase AC asynchronous motor with synchronous belt and drive shaft rotation. This ensures that the rotation of the spindle on both sides of the winding is equal speed and synchronized. Through processing to improve the assembly accuracy, and then ensure the concentricity of the line mold and winding quality.

2、Lineup mechanism

The wire arrangement mechanism generally adopts stepping motor as the driving source of the wire arrangement mechanism of low-speed winding machine, mainly using stepping motor to drive the ball screw rotation by synchronous toothed belt or using the way to drive the ball screw rotation by coupling. This paper adopts the first way, that is, the stepping motor drives the ball screw rotation via synchronous toothed belt. Since the ball screw and the stepper motor shaft are connected in a flexible way, the requirements for the positioning surface of the stepper motor base and the assembly requirements of the ball screw and the guiding rod are reduced accordingly. In order to meet the design requirements, the compound lineup method is used to improve the lineup mechanism in a targeted manner. The commutation control of the winding mechanism is the key to control the quality of the wound coils. In the design, the asynchronous motor can be controlled by software to match the speed and time during commutation so that it will not cause pressure stacking or loosening, etc.

3. Tension mechanism

When winding fine enameled wire and precious metal alloy fine wire, due to the fine wire diameter, if the tension is too large, the wire will be broken or stretched out, increasing the DC resistance of the coil; if the tension is too small, the phenomenon of disordered line will occur, reducing the winding quality. Because the device’s wire release tensioner is fixed on the ball screw wire row rod, so the tension is controlled by felt compression. In the actual production process, the tension device can be added in the important process links to control the size of the tension to ensure that the row of wires is neat, no pressure stack, no loose, and can fully meet the needs of different wire diameters after careful adjustment.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]