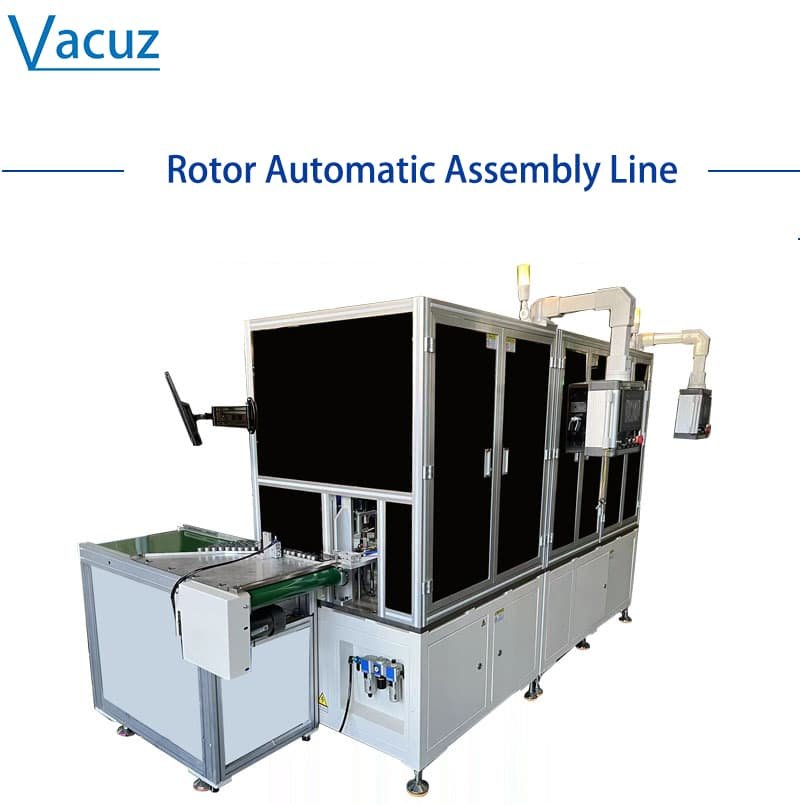

Brushless motor stator and rotor mass production, many factories have adopted to start using special production lines, compared with the traditional manual semi-automatic production mode, efficiency and quality are greatly improved, but also save labor, improve the image of the factory.

The main processes are as follows:

Completion of automatic stator winding, terminal insertion, touch welding and stator performance testing, stator into the bearing housing, shaft into the shaft, gluing, loading magnetic strips up, drying, magnetization and stator-rotor assembly processes.

Rotor assembly line features and advantages:

1. the stator-rotor section of the whole production line can basically be produced unmanned, requiring only special posts to be watched;

2. stable production of stator-rotor assembly and easy operation and debugging;

3. the whole data can be collected, monitored and stored in real time, at a glance;

4. important parts are equipped with testing equipment to detect defective and faulty products;

5. customized according to customer process, good product consistency and stable quality;

6. The stator assembly line can be non-standard customized, and the professional production line can be customized according to the customer’s needs.

What are the main processes of brushless motor stator and rotor assembly line? What are the characteristics and advantages? The above has done a simple explanation, I hope these tips can help you!

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]