There are many processes, procedures and equipment required for the assembly of the stator and rotor of drone motors. It is necessary to do a good analysis and choose the right equipment. Vacuz combines relevant content and integrates it, hoping to help everyone!

1. Assembly core process and process

The assembly of the stator and rotor of drone motors does require precision technology to ensure the uniformity of air gap, magnetic flux stability and dynamic balance performance. The key process can be divided into three steps: stator pretreatment and assembly, rotor pretreatment and assembly, and stator and rotor assembly and inspection.

1. Stator pretreatment and assembly

Iron core lamination and shaping : Use a high-speed punch press to punch silicon steel sheets into stator cores, and fix the number of layers through the stacking riveting process to ensure the compactness and uniformity of the core. After lamination, use a hydraulic press to apply appropriate pressure to eliminate the lamination gap.

Coil winding and wire embedding : The fully automatic winding machine winds the enameled wire into a coil of the designed shape, and then the robot arm or manual embeds the coil into the core slot. After embedding, it is varnished (such as vacuum varnishing) to enhance the insulation performance.

Casing insertion and fixing: The stator assembly is inserted into the inner hole of the aluminum alloy casing, and the hydraulic/pneumatic self-centering quick-change multi-station fixture is used to achieve rapid positioning to ensure concentricity and assembly accuracy.

2. Rotor pretreatment and assembly

Rotor shaft processing: The rotor shaft is processed through turning, grinding, rolling and other processes to ensure that the tolerance of key dimensions is controlled within a certain range (such as ±0.005mm), and the surface roughness must also meet the standard.

Magnetic steel assembly and dispensing: The automated equipment installs the NdFeB magnet into the rotor core slot according to the designed polarity, and the dispensing machine fills the epoxy resin glue between the magnet and the core. After curing, the tensile strength of the magnet must reach the specified value.

Dynamic balancing test and correction: The rotor is installed on the dynamic balancing machine, and the imbalance is adjusted by de-weighting or adding weight to ensure that the remaining imbalance is within the allowable range.

3. Stator and rotor assembly and inspection

Assembly mechanism drive: The servo motor drives the rotor fixture to rotate, and the high-precision encoder monitors the rotor position in real time to ensure that the alignment error with the stator is within the allowable range (such as ≤0.05mm).

Assembly pressure control: The assembly force is applied by the air pressure or hydraulic system, and the pressure range must be strictly controlled within ±5% of the design value (such as 1000N±50N) to avoid uneven air gap due to improper pressure.

Missing assembly detection and performance test: After assembly, the sensor automatically detects whether there is any missing magnet or coil, and then performs back electromotive force test, insulation withstand voltage test, etc. to ensure that the electrical performance meets the standard.

2. Analysis of key equipment and functions

In the final assembly process, it is crucial to rely on multiple types of high-precision equipment to achieve automation and quality control. The core equipment includes stator assembly equipment, rotor assembly equipment, and assembly and inspection equipment.

1. Stator assembly equipment

Fully automatic winding machine: supports multi-wire winding, equipped with high-precision tensioner to ensure coil filling rate and winding quality.

Hydraulic shaping machine: applies pressure through the hydraulic system to eliminate the core stacking gap, and cooperates with the laser measuring instrument to monitor the core height in real time to ensure that the tolerance is controlled within the allowable range.

Vacuum varnishing equipment: immerses the stator in insulating varnish under vacuum environment, and controls the varnishing time through the circulation pump to ensure the uniformity of the paint film and insulation performance.

2. Rotor assembly equipment

Magnetic steel assembly machine: uses a mechanical arm or vibration plate to automatically load materials, and identifies the polarity of the magnetic steel through the visual system to ensure assembly accuracy and efficiency.

Dynamic balancing machine: supports G1-level precision testing, equipped with a laser speed measurement system and a de-weighting drilling device, which can correct the imbalance in real time.

Rotor shaft machining center: integrates turning, grinding, rolling cutting and other functions, controls the machining path through the CNC system to ensure that the key dimensional tolerances meet the standards.

3. Assembly and testing equipment

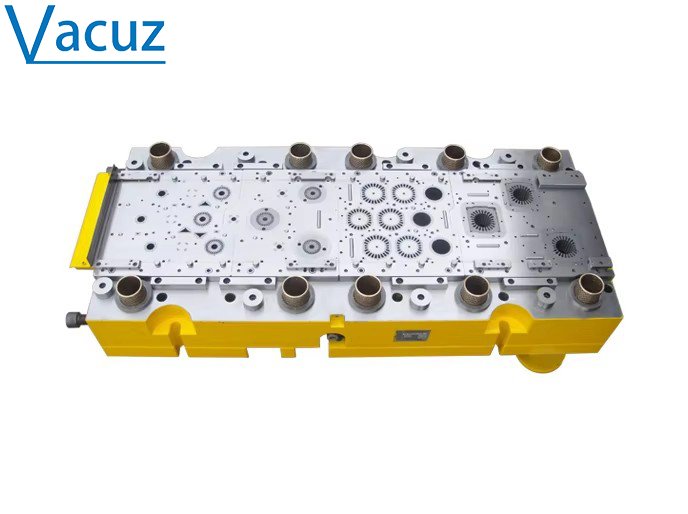

Stator-rotor assembly machine: Using servo press-fit technology, high-precision assembly and positioning are achieved through pressure sensors and linear motor guides.

Back EMF tester: The motor back EMF signal is collected through the Hall sensor, and the waveform is analyzed through the oscilloscope to ensure that the fluctuation rate is within the allowable range.

Insulation withstand voltage tester: The output voltage range is wide, and the test time and leakage current threshold can be set to automatically determine whether the insulation performance is qualified.

3. Equipment selection and manufacturer recommendation

When selecting equipment, it is necessary to comprehensively evaluate accuracy, stability and after-sales service. The following are some recommended manufacturers and equipment:

Stator winding machine

Equipment features: Vacuz winding machine equipment supports multi-wire parallel winding and high-speed winding, equipped with imported servo motors and tungsten carbide wire nozzles, suitable for high-precision stator production.

Stator and rotor assembly machine

Equipment features: The Vacuz assembly machine uses servo press technology, with high pressure control accuracy, and can realize automatic assembly and detection of stators and rotors with high-precision guide rails. These devices are usually highly flexible and adaptable, and can meet the assembly needs of motors of different models.

In summary, the assembly process of drone motor stators and rotors requires strict control of process parameters and equipment accuracy in each link. By selecting suitable equipment and manufacturers, production efficiency and product quality can be greatly improved.

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]