Brushless motor stator enameled wire has very high requirements. During high-speed operation, if the enameled wire does not meet the required quality, it is prone to breakage or damage. So, what are the requirements for enameled wire in brushless stator winding machines? How can we ensure that enameled wire is not prone to breakage? Vacuz will explain.

1. Conductivity

As the medium for transmitting current, the conductivity of enameled wire directly affects the efficiency and energy consumption of the motor. Copper enameled wire with excellent conductivity should be preferred to minimize energy loss during transmission. Enameled wire with poor conductivity will increase motor heat, reduce efficiency, and even cause overheating failure.

2. High-temperature resistance

During motor operation, the stator winding temperature can reach 120°C to 180°C. Therefore, enameled wire must maintain stable insulation properties in high-temperature environments (e.g., above 150°C) to prevent aging or shedding of the insulation layer. Inadequate high-temperature resistance can lead to short circuits or breakdown, compromising safe motor operation.

3. Wear Resistance and Mechanical Strength

During high-speed winding, friction between the enameled wire and the guide pulley and die can easily cause the wire diameter to thin or the insulation to peel. Therefore, the enameled wire surface requires a wear-resistant coating, such as polyimide (PAI) or polytetrafluoroethylene (PTFE), to withstand friction and vibration during winding and prevent insulation damage.

4. Voltage Withstand and Insulation Performance

The stator winding voltage of a brushless motor typically ranges from 24V to 400V. The insulation layer must withstand 1.5 to 2 times the motor’s rated voltage to prevent high-voltage breakdown or leakage. Excellent insulation performance is key to preventing current leakage, electric shock, and short-circuit failures.

5. Matching Wire Diameter and Specifications

The wire diameter should be selected based on the motor power, slot fill rate, and the winding machine’s tension capacity. Avoid wires that are too thick or too thin. A thicker wire diameter increases winding difficulty and increases slot fill rate, while a thinner wire diameter results in insufficient current carrying capacity. For example, a 0.1mm wire diameter is suitable for winding fine wire, while wire diameters exceeding 1.0mm require a tension control system and a precision winding machine.

6. Quality Stability

Choose enameled wire from a reputable manufacturer to ensure consistent performance from batch to batch and reduce the risk of wire breakage. Enameled wire with high quality fluctuations is prone to problems such as uneven wire diameter and varying insulation thickness, which can affect motor performance.

Wire Breakage Prevention Solutions:

1. Optimize Winding Machine Configuration and Commissioning

Tension Control: Use a high-precision tensioner to set the appropriate tension based on the wire diameter (e.g., ≤0.5N for a 0.1mm wire diameter). Avoid excessive tension that may cause wire deformation, or too little tension that may cause the coil to loosen.

Speed Control: Winding speeds must be below the equipment limit (e.g., ≤800 rpm) and utilize a “slow start – acceleration – constant speed” pattern. During high-speed operation (>600 rpm), a vibration damping device should be used to stabilize the force applied to the wire.

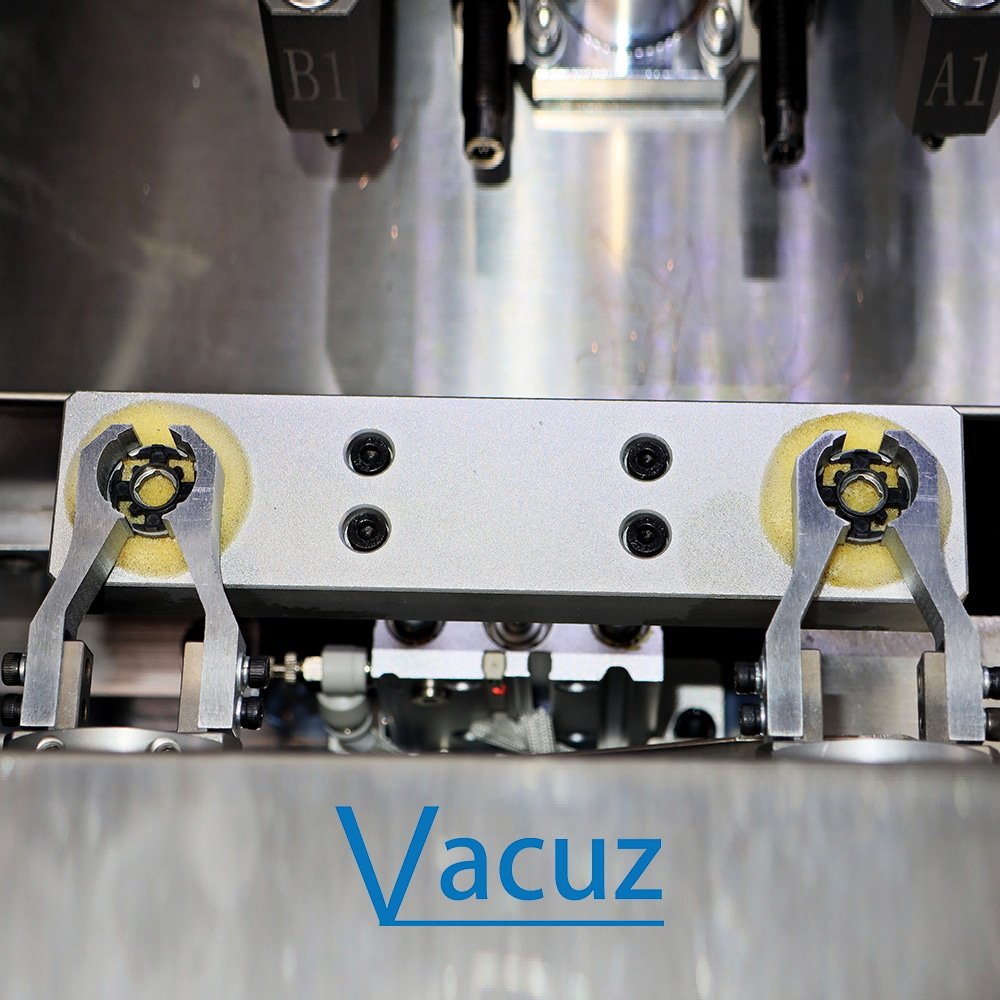

Die and Guide Roller Accuracy: The die inner diameter should be 0.05-0.1mm larger than the wire diameter to avoid scratching the wire. The guide roll surface should be smooth and cleaned regularly to remove foreign matter (such as copper shavings and oil stains).

2. Standardized Enameled Wire Usage and Storage

Wire Selection: Verify that the wire diameter and material meet design requirements. Polyimide or PTFE-coated enameled wire is preferred for improved wear resistance.

Storage: Store in a dry (humidity <60%), light-proof environment to prevent insulation degradation. Wire reels should be placed horizontally to prevent deformation and localized stress.

3. Process Parameter Optimization

Wire Spacing: Set appropriate spacing based on wire diameter to avoid friction between wires.

Winding Direction: Use a uniform winding direction to reduce torsional stress on the wire.

Wire Feeding Method: Design a smooth wire feeding path to avoid scratches on the wire caused by right-angle turns or sharp edges.

4. Quality Inspection and Prevention

Incoming Inspection: Insulation thickness is measured using a micron-level thickness gauge to ensure compliance with standards. Voltage and salt spray tests are also performed.

In-Process Inspection: After every 100 stators are wound, the wire surface is inspected for scratches, discoloration, or stretch marks. Wire break locations are recorded to determine whether they are caused by equipment failure or wire defects.

Brushless stator winding machines require enameled wire with balanced conductivity, temperature resistance, wear resistance, and specification compatibility. Wire break prevention requires a coordinated approach encompassing equipment commissioning, process optimization, material selection, and quality inspection. This refined control significantly improves winding efficiency and product reliability.

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]