Brushless motor stator winding often uses specialized winding machines. Many people ask about the speed of the winding machine. Many factors influence speed, requiring comprehensive analysis. Which factors are most relevant, and how can we ensure winding quality?

I. In-depth Analysis of Factors Affecting Winding Machine Speed

1. Equipment Configuration Optimization

Intelligent Upgrade: An AI-powered visual positioning system is introduced. A camera captures the stator slot position in real time, automatically correcting the winding path and reducing speed loss due to mechanical positioning deviation.

Modular Design: Quickly replaceable winding modules (such as nozzles and tensioners) are used for plug-and-play operation, adapting to different wire diameters and stator structures, reducing downtime and adjustment time.

2. Stator Parameter Adaptation Strategy

Dynamic Wire Diameter-Speed Matching: A mathematical model is established to link wire diameter and winding speed, allowing the PLC to calculate the optimal speed in real time.

Complex Stator Preprocessing: For stators with skewed or irregular slots, the winding path is simulated in advance using simulation software to generate an optimized program, reducing on-site commissioning time.

3. Process Design Innovations

High-Speed Wire Arranging Technology: Utilizing a “segmented slow speed followed by overall high speed” strategy, the speed is reduced in the slot area to ensure accurate wire routing, while the speed is increased to the rated value in non-slot areas, balancing efficiency and quality.

Quick Mold Change System: A quick-change fixture is designed that uses an RFID chip to identify the mold model and automatically adjusts the corresponding process parameters, reducing changeover time from 2 hours to 15 minutes.

II. Upgraded Winding Quality Assurance Measures

1. Equipment Selection and Configuration Recommendations

Closed-Loop Tension Control: A tensioner with a pressure sensor provides real-time tension feedback to the control system, forming a closed-loop adjustment loop to prevent tension instability caused by air pressure fluctuations or wire elasticity.

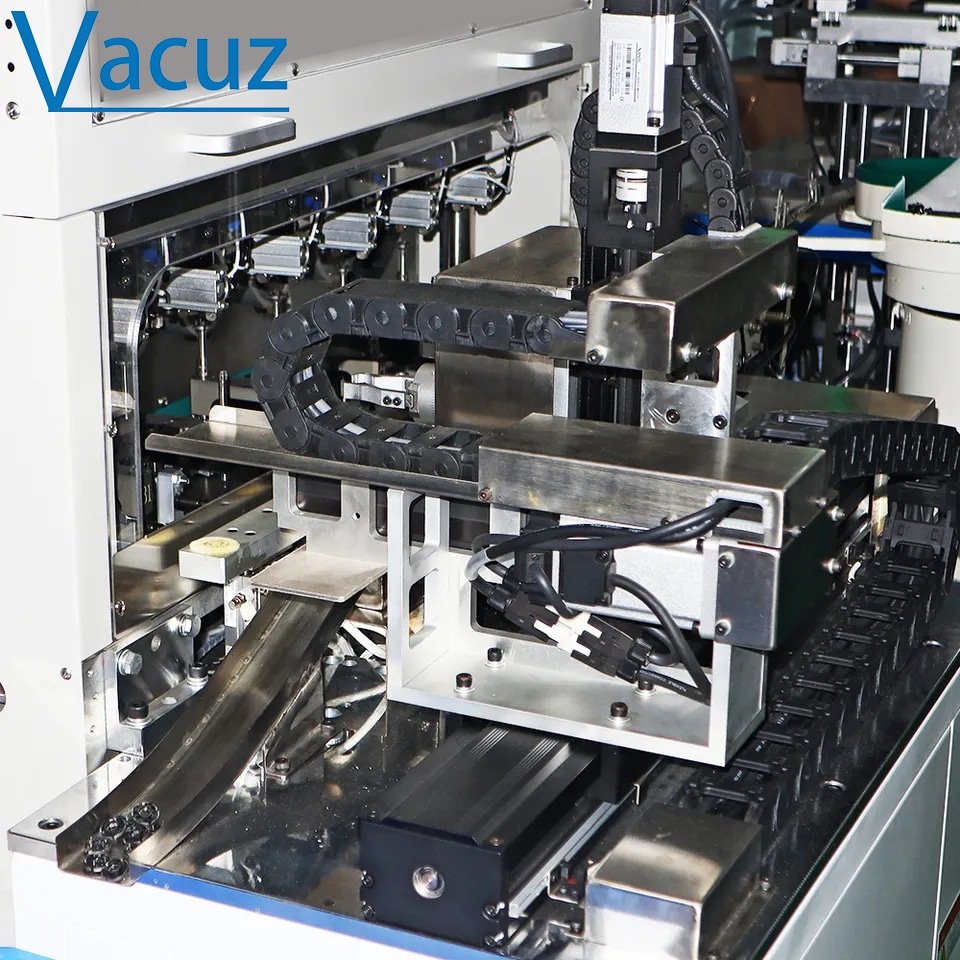

Multi-Axis Linkage Technology: A five-axis winding machine utilizes independent control of the nozzle’s X/Y/Z axes and the stator’s rotation axis to achieve accurate winding of complex slots, minimizing manual intervention.

2. Process Optimization and Standardization Practices

Digital Process Library: Builds a process database encompassing stator parameters, wire diameter, slot profile, and other dimensions. Algorithms automatically generate appropriate winding programs, reducing reliance on human experience.

Error-Proofing Design: Locating pins and sensors are added to the mold. When stator placement deviation exceeds 0.1mm, the machine automatically issues an alarm and stops operation, preventing batch quality issues.

3. Enhanced Process Monitoring and Inspection

Online Quality Inspection: An integrated laser rangefinder monitors slot fill rate in real time. When the actual value falls below the set value, the system automatically adjusts the wire spacing or reduces the speed to compensate.

Data Traceability System: Records data such as tension, speed, and alarms during the winding process for each machine, generating quality reports to facilitate problem tracing and process improvement.

4. Standardized Maintenance and Maintenance

Predictive Maintenance: Vibration sensors monitor the wear of key components such as lead screw guides and bearings, providing early warning of replacement needs and avoiding downtime caused by unexpected failures.

Automated Cleaning: An automatic dust blower cleans the equipment between windings, reducing the impact of manual operation on production flow.

III. Industry Trends and Cutting-Edge Technologies

Carbon Fiber Wire Applications: With the increasing demand for lightweight motors, carbon fiber wire is becoming increasingly popular. A dedicated tension control system is needed to address its low elastic modulus and susceptibility to breakage.

Coreless Stator Winding: Developing flexible winding technology for coreless motors uses magnetic levitation guides to achieve contactless winding of wire, improving winding density and efficiency.

What factors influence the speed of a brushless stator winding machine? How can winding quality be ensured? Vacuz has briefly explained this above. We hope this information will be helpful!

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]