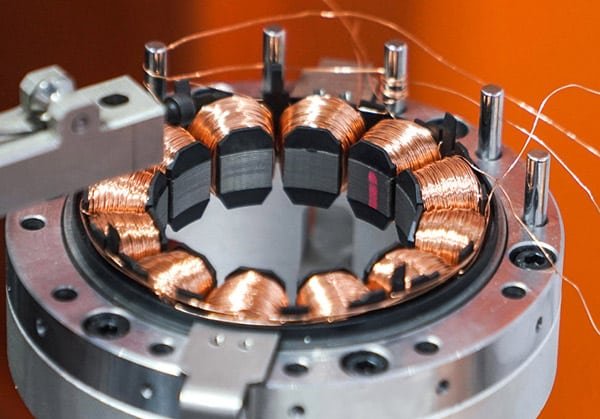

Previous motor winding work, most of the time are manual, and then slowly developed, there is a manual semi-automatic winding machine, to these years, many manufacturers are using automatic winding machine, automatic winding machine is not only fast, and free your hands, a person can look at several machines, to the motor manufacturers have brought a lot of convenience. So fully automatic winding machine compared to manual semi-automatic ordinary winding machine in the end what are the advantages?

1. Automation, using PLC control system, can accurately control the winding speed, number of ties, time, etc., and debugging is also relatively simple.

2. Intelligent, can be programmed by yourself, can also adjust the program, can realize different winding programs according to customer requirements, winding and lining up is done automatically; one person can watch several machines, only need to feed.

3. Humanized, simple training can be inaugurated, visualization interface, operation is clear at a glance, can stop at any time, and there will be an alarm if there is a problem.

4. Diversification, in a certain diameter range, automatic winding machine can be universal, only need to replace the mold can be, a machine multi-purpose, can save a lot of money to the motor manufacturers.

Of course, today there are many manufacturers still use manual semi-automatic mode, small quantities can be, large quantities are a bit strained, with a fully automatic winding machine, a person can complete the work of the past ten or so people, greatly improving production efficiency, reducing business costs, and as long as the quality of the equipment is excellent, good precision, many times, winding the line more neatly than the manual, do not hurt the line.

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]