What is the difference between a stepper motor and a servo motor? What is the difference in working principle? Many friends still do not know very well, Vacuz to introduce you! I hope it can help you!

The difference between stepper motors and servo motors is that stepper motors can be controlled by precise positioning, while servo motors need to adjust the position in real time through the feedback machine. Stepper motors are usually used for low-precision applications such as printing equipment, CNC machine tools, etc.; and servo motors are suitable for high-speed high-torque, as well as the need for accurate position and angle control automation equipment, robots, flying machines, etc..

Its working principle is also different, stepper machine through the count of input pulses to achieve shift, while the servo electric through the feedback signal to adjust the speed and position, as follows:

The stepper motor works by controlling the input pulse signal, which makes the motor magnetic field change, while driving the motor rotation. A stepper usually consists of a fixed stator and a rotor wound inside the stator. Given a complete set of pulses, the rotor is allowed to rotate clockwise or counterclockwise by a fixed angle, which is the stepping angle. Then, the next set of pulses is given and the above steps are repeated until the motor turns to the desired position. Because step motors are step-by-step, precise control of rotation, so they are widely used in systems that require high precision positioning such as printers, CNC machine tools, robots, etc.

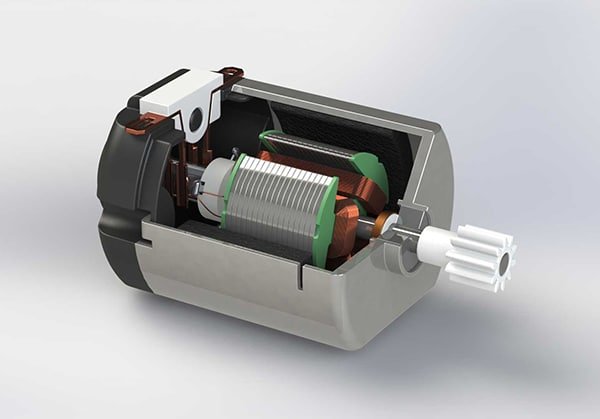

Servo motors work by receiving signals from the control system, detecting them with the built-in encoder, and sending feedback information back to the control system to adjust the motor rotation and direction so that it eventually rotates to the specified position and speed. Servo motor usually consists of motor, reducer, encoder, controller part. The motor is the source of driving force, the reducer is used to increase the output torque and reduce the speed, the encoder is used to monitor the motor position information in real time, and the controller is used to realize the precise system according to the information returned from the encoder. Servo motors are widely used in automation equipment that requires high precision positioning and speed adjustment, printing equipment, textile equipment, medical equipment, etc.

What is the difference between stepper motor and servo motor? What is the difference in working principle? The above has made a simple explanation, I hope that these tips can help you!

WhatsApp/Wechat: +86 13075286997

E-posta: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]