What precautions should be taken when winding thick wire with a brushless motor winding machine? Vacuz combines industry practices with technological innovations to provide a comprehensive overview of equipment optimization, process upgrades, and stator parameter adaptation, aiming to improve the efficiency and quality stability of thick wire winding. We hope this helps!

Dış Stator Titreşimli Plaka Besleme Vacuz Tam Otomatik BLDC Fırçasız Drone İHA Soğutma Fanı Motor Bobini Uçan Çatal Sarma Makinesi Üreticisi

I. In-depth Considerations for Winding Thick Wire

1. Speed Control Strategy

Dynamic Speed Control System: Utilizes inverter and encoder feedback control to adjust the winding speed in real time based on the wire diameter. For example, for every 0.2mm increase in wire diameter, the speed is automatically reduced by 15%, and a tension compensation algorithm is triggered to prevent wire breakage caused by sudden speed changes.

Low-Speed Start Technology: During the initial winding phase, the winding machine operates at a low speed of 50-80 RPM to ensure the wire end is securely fixed before increasing speed, reducing the risk of wire breakage during the initial stage.

2. Innovations in Wire Bending Processes

Hot Bending Technology: For wires thicker than 2.0mm, localized heating (100-120°C) is used before bending to minimize paint peeling.

3D-Printed Guide Tooling: Customized 3D-printed guide blocks based on the stator slot profile replace traditional metal molds, reducing the contact area between the wire and the tooling and minimizing the risk of scratches.

3. Tensioner Selection and Adjustment

Intelligent Tension Closed-Loop Control: A tensioner with a pressure sensor is selected, providing real-time tension feedback to the PLC for closed-loop control.

Multi-Stage Tension Setting: Differentiated tension values can be set for different winding stages (such as starting, winding, and ending). For example, tension can be reduced by 20% at the beginning and increased by 10% at the end to prevent loosening or breakage of the wire ends.

II. Equipment Requirements and Upgrade Plan

1. Optimization of Equipment Type Selection

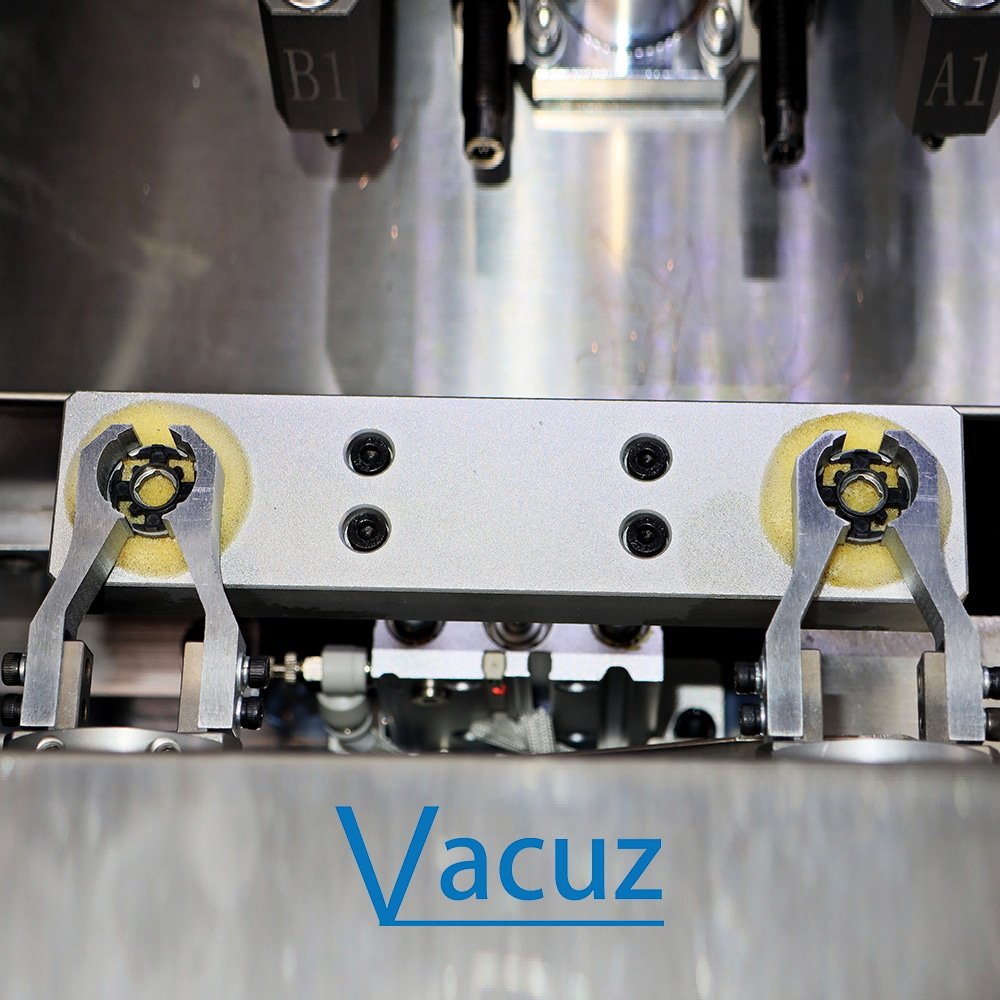

Combined Winding Machine: Targeting thick wire and complex stator slot profiles, a “flying fork + needle” combined winding machine has been developed. This machine quickly switches between winding modes, accommodating both external and internal winding requirements. For example, one model can automatically switch between wire diameters from 0.8 to 3.0 mm, reducing changeover time to just 10 minutes.

High-Speed Flying Fork Outer Winding Machine: Utilizing a lightweight flying fork head and a high-speed servo motor, the outer winding speed is increased to 1200 RPM (compared to 800 RPM on conventional models). A pneumatic balancing device also reduces vibration.

2. Enhanced Equipment Performance Requirements

High-Rigidity Bed Design: Utilizing a cast iron and steel composite bed structure, the bed increases rigidity by 30%, reducing vibration during high-speed winding.

Vision Positioning System: Integrating an industrial camera and AI algorithm, the system identifies stator slot positions in real time and automatically adjusts the winding path.

3. Intelligent Equipment Maintenance and Care

IoT Monitoring: Vibration sensors are installed on key components (such as lead screws and bearings) to analyze wear trends through the cloud, providing early warning of replacement needs.

Automatic Lubrication System: Utilizing a metering pump and nozzle design, the system automatically lubricates the lead screw guide rails at preset intervals, preventing under- or over-lubrication caused by manual lubrication.

III. Refining Stator Parameter Requirements

1. Stator Stacking Adaptation Strategy

Segmented Winding Technology: For stators with stacking thickness exceeding 150mm, a “top-bottom segmented winding” process is used. The lower half is wound first, followed by the upper half, to reduce winding oscillation.

Dynamic Stacking Compensation: The actual stator stacking thickness is input into the winding program to automatically adjust the wire spacing and tension. For example, for every 50mm increase in stacking thickness, the wire spacing is increased by 0.2mm to prevent wire squeezing.

2. Slot Spacing Optimization

Simulation Analysis: Using electromagnetic simulation software, the electric field distribution at different slot spacings is simulated to optimize slot design.

Adjustable Slot Die: A die with adjustable slot spacing is designed, enabling quick adaptation by replacing positioning blocks.

Vacuz İki İstasyonlu Hassas Servo BLDC Fırçasız Motor E Bisiklet Stator Bobini Uçan Çatal Sarma Makinesi

What should be considered when winding thick wire on a brushless motor winding machine? What are the Vacuz equipment and stator parameter requirements? This brief introduction is provided above. I hope this information is helpful!

E-posta: sales@vacuz.com