In recent years, the use of automatic winding machines has gradually become more widespread and more and more manufacturers are using them, saying goodbye to the traditional manual semi-automatic mode. This machine has higher production efficiency, greatly reduces the reliance on manual labor, one operator can look after multiple machines at the same time, and the production quality is more stable, suitable for high-quality batch motor winding needs. Let’s take a look at its working principle and debugging method!

I. The working principle of automatic winding machine

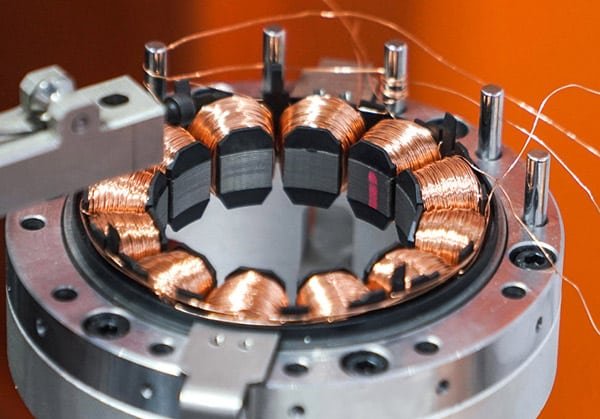

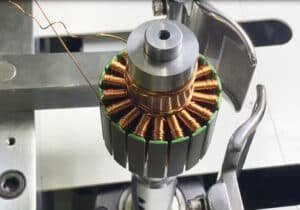

Automatic winding machine is composed of control system, line up mechanism, winding system, mold holder, etc. Under the program control, it can realize the actions of starting, acceleration and deceleration, stopping, running, forward and reverse, cross slot, etc. It can ensure the constant tension, straightening, releasing and winding, and ensure the stable and normal winding process.

II. Automatic winding machine debugging method

1. Start the machine to run at no load, try to increase or decrease the speed, observe whether there is any problem with the wire nozzle and mold simulation winding, whether the whole machine runs smoothly, whether there is any abnormal noise, etc.

2. Check the validity of each function one by one according to the manual of automatic winding machine, which is also the process of familiarizing with the equipment. After the initial understanding of the equipment function, you should find out the corresponding equipment function according to the winding process of your product, and check whether the equipment function meets the winding requirements according to the process.

3. Familiar with the equipment parameters, the allowable wire diameter of the equipment, the load, the width of the line and its precision, etc. These parameters are the basic data to determine whether the equipment meets the winding requirements.

4. Regarding the tension adjustment of the winding machine, usually, the larger the diameter of the winding, the greater the tension, and the tension adjustment range of different manufacturers’ equipment is different. Tension adjustment is the key setting. Different wire diameters have different safety tension ranges.

5. Measure the data of the winding mold. It should be noted that the width and height of the die matches the winding bar. Too tight will affect the loading and unloading of the die, while too loose will cause the die to shake and affect the winding effect.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]