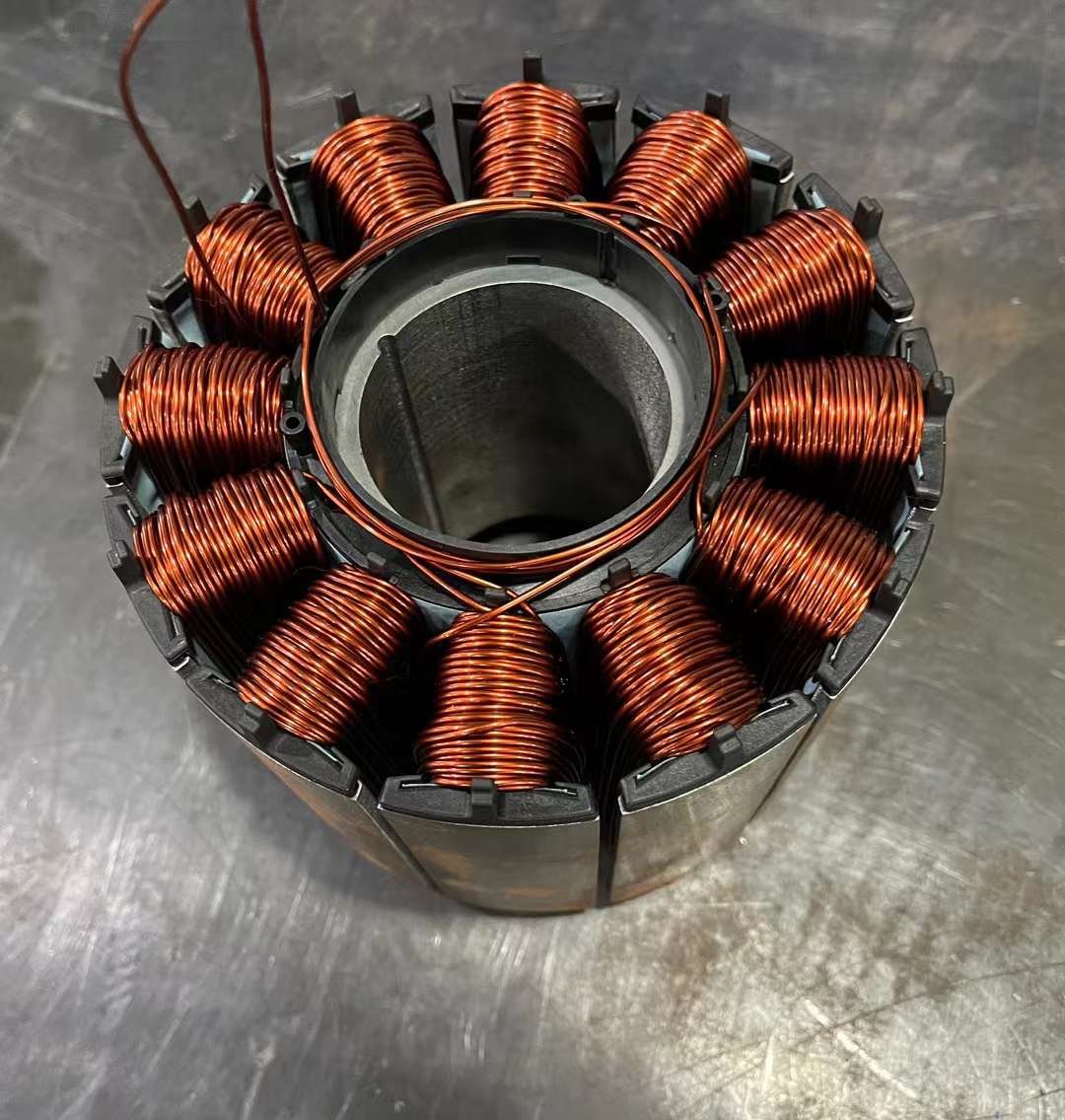

Motor stator winding have certain standards, for the winding machine is the same, only meet the requirements of the winding, coupled with well configured winding machine equipment, in order to ensure that the winding effect, then how to control the motor stator winding standards? How to adjust the winding machine parameters and configuration? The following Vacuz briefly explain it to you!

First, the control of motor stator winding standards:

1. Slot size and direction: to ensure that the slot size is suitable for the smooth passage of the enameled wire to avoid scratching. According to the direction of the slot to choose the right type of winding machine, such as internal winding machine or flying fork external winding machine.

2. Outer diameter and inner diameter: Select the type of winding machine according to the outer diameter and inner diameter of the stator, and make sure that the number of working stations is reasonable.

3. Stator height: Higher stator heights require special processes or advanced winding machines to minimize the risk of wire injury.

4. Enameled wire diameter: the diameter of the wire affects the winding speed and equipment requirements, need to reasonably select the winding machine and tension settings.

5. Number of turns and slots: If the number of turns and wire diameter is fine, it is necessary to increase the winding speed; if the number of slots is large, it is necessary to change the winding machine.

6. Slot distance: Adjust the slot distance according to the wire diameter and multi-wire parallel winding situation to ensure smooth winding.

7. Winding method and tension control: pay attention to the arrangement and tension control of single wire winding and multi-wire parallel winding to ensure even tension.

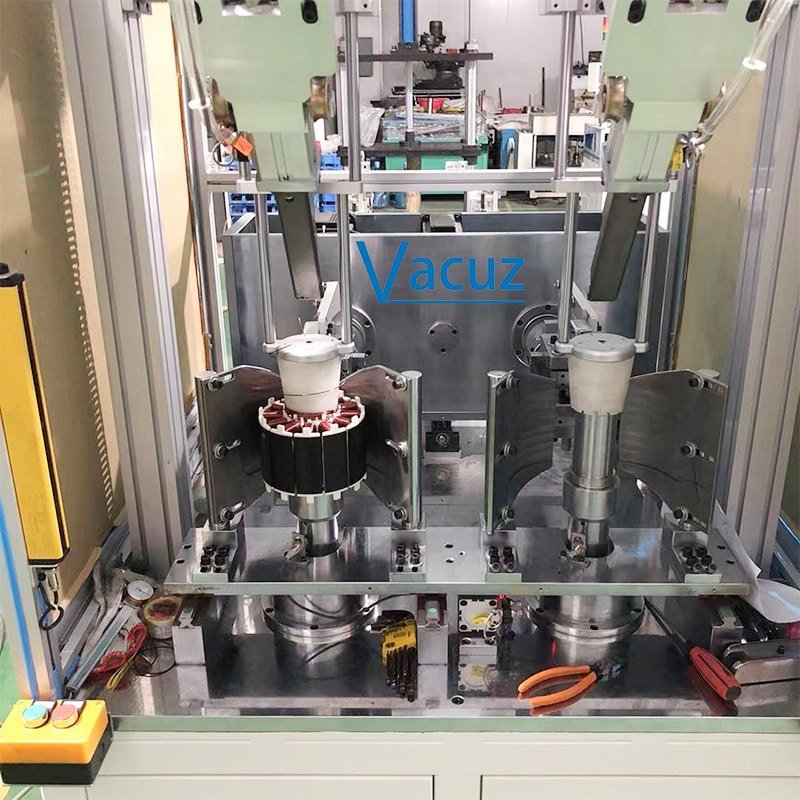

Adjustment of parameters and configuration of the winding machine

1. Debugging machine: check the workbench, mold fixture and transmission range, to ensure that there is no debris and the power supply is connected correctly. Debug the position of each component to ensure that there is no offset.

2. Setting parameters: According to the stator parameters and winding requirements, accurately set the parameters of the winding machine, such as the program number, the number of turns of the coil and so on.

3. Tensioner Adjustment: According to the type of wire and wire diameter size, adjust the tensioner range to ensure that the tension is moderate.

4. Mold device and test: Tighten the mold device to avoid loosening or shaking when winding. Conduct manual running test to ensure that the orientation of each component is aligned.

5. Winding speed control: Control the winding speed within the appropriate range to avoid excessive speed leading to wire breakage.

6. Salt water test and safe operation: carry out salt water test after completion of winding to ensure that the stator meets the requirements.

7. Observe the safety operation regulations when using the winding machine to ensure personal safety.

To summarize, by accurately controlling the motor stator winding standard and reasonably adjusting the parameters and configuration of the winding machine, the quality and efficiency of the motor stator winding can be significantly improved.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]