The production of brushless motor stators requires specialized winding machines. Different products require different winding machines, and different winding machine manufacturers also have varying designs and technologies. So, what are the specific differences in the technologies and equipment used by stator winding machine manufacturers? How can you find a reliable, high-quality manufacturer? Vacuz explains.

I. Technical Differences: Core Functions and Process Compatibility

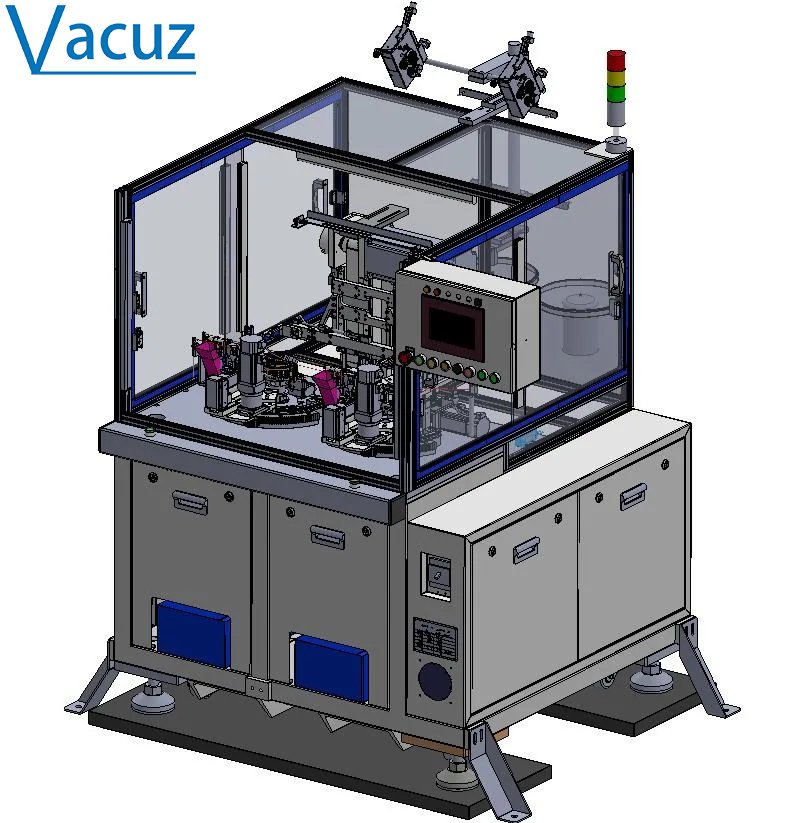

1. Differences in Automation Level

Fully Automatic Winding Machines: The current trend is integrating AI-powered visual inspection systems. For example, some manufacturers have implemented real-time inspection of wire diameter, number of turns, and insulation integrity during the winding process, achieving an automatic rejection rate of 99.8% for defective products.

Servo Precision Winding Machines: High-precision servo motor drive technology has been upgraded to “direct-drive servo,” reducing transmission components and improving response speed and accuracy.

2. Differences in Customization Capabilities

3. Differences in Intelligence and Integration

Data Traceability and Intelligent Management: Integrating 5G+ Industrial Internet technologies enables remote monitoring and predictive maintenance, reducing the risk of downtime.

Full-Process Automation: Supports integration with AGVs, high-bay warehouses, and other logistics equipment, enabling fully unmanned production.

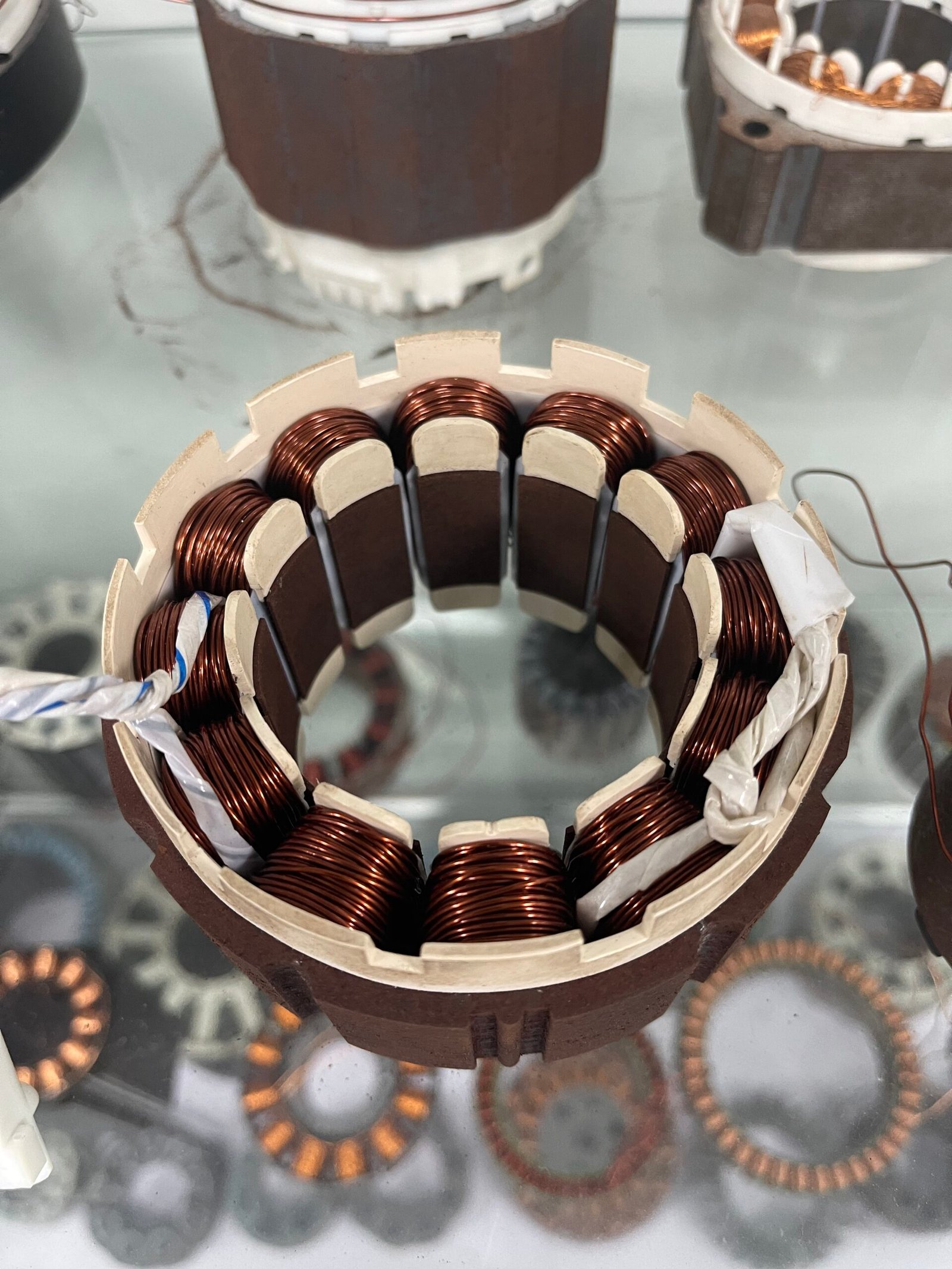

II. Equipment Differences: Performance Parameters and Applicable Scenarios

1. Winding Speed and Efficiency

High-Speed Equipment: Professional brushless motor winding machines. Using a carbon fiber spindle can further increase speed and reduce energy consumption.

Medium-Speed Equipment: Consider whether it supports variable frequency speed regulation to accommodate winding requirements for different wire diameters and turns.

2. Winding Accuracy and Stability

High-Precision Equipment: Approaching internationally advanced standards, with reliable accuracy and stability.

Stability Guarantee: Long-term, 24/7 operation is possible. Inquire about whether a redundant design (such as dual power supplies and dual controllers) is used to enhance reliability.

3. Equipment Specifications and Scalability

Multi-Station Design: Inquire about whether it supports online inspection and automatic sorting to improve production capacity and quality.

Modular Structure: Pay attention to whether the modular design supports quick replacement of winding heads (e.g., from two to four heads) to accommodate varying production capacity needs.

III. Strategies for Selecting High-Quality Manufacturers:

1. Technical Capability Assessment

Core Patents and Certifications: Prioritize manufacturers with “National High-Tech Enterprise” certification.

R&D Team and Investment: Examine whether the manufacturer participates in the development of industry standards.

2. Equipment Performance Verification

Field Testing and Case Study: Manufacturers are required to provide at least three case studies from customers in the same industry and conduct on-site inspections of their equipment operation.

Third-Party Inspection Reports: Refer to evaluation reports from the China Machinery Industry Federation or the China Electrical Equipment Industry Association, prioritizing manufacturers with high rankings in metrics such as “winding accuracy,” “stability,” and “energy efficiency.”

3. Production Capacity and Quality Control

Production Lines and Equipment: Investigate whether the manufacturer has automated production lines (such as robotic loading and unloading and automatic spray painting) to improve production efficiency and consistency.

Quality Inspection Process: Verify whether the manufacturer has established a full-process traceability system, enabling traceability from raw material batches to finished product serial numbers.

4. After-Sales Service and Support

Response Time and Scope: Prioritize manufacturers offering nationwide warranty services.

Training and Parts Supply: Verify whether the manufacturer offers an online training platform, providing comprehensive services including process consulting, equipment customization, and personnel training.

5. Comprehensive Cost-Effectiveness Evaluation

Life Cycle Cost: Compare equipment price, energy consumption, maintenance costs, and service life.

Customized Services: Select a manufacturer offering rapid prototyping services based on your needs to shorten customization cycles.

What are the differences in technology and equipment between stator winding machine manufacturers? How can you find a reliable, high-quality manufacturer? Vacuz has provided a brief explanation above, and we hope it will be helpful!

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]