Brushless and brushed motors are two of the most commonly used motors. Brushless motors wind the enameled wire directly onto the rotor, while brushless motors wind the enameled wire onto the stator. Although both utilize flying fork winding machines, there are some differences. So, what are the similarities and differences between fully automatic stator and rotor winding machines? Vacuz will briefly explain them below!

1. Common Technology Upgrades: Intelligence and Data-Driven

AI Visual Inspection: Modern winding machines now incorporate AI algorithms that can identify defects such as wire breaks and misaligned wires in real time, with an accuracy of 0.02mm.

Digital Twin Technology: Optimizes winding paths through virtual simulation, reducing trial-and-error costs. For example, stator winding machines can simulate coil fill rates for different slot configurations and adjust parameters in advance.

Adaptive Tension Control: Using a pressure sensor and closed-loop PID algorithm, the tension is dynamically adjusted (±1% fluctuation) to accommodate different materials, such as copper and aluminum wires.

2. Winding Objects and Process Challenges: Breakthroughs in Sub-scenarios

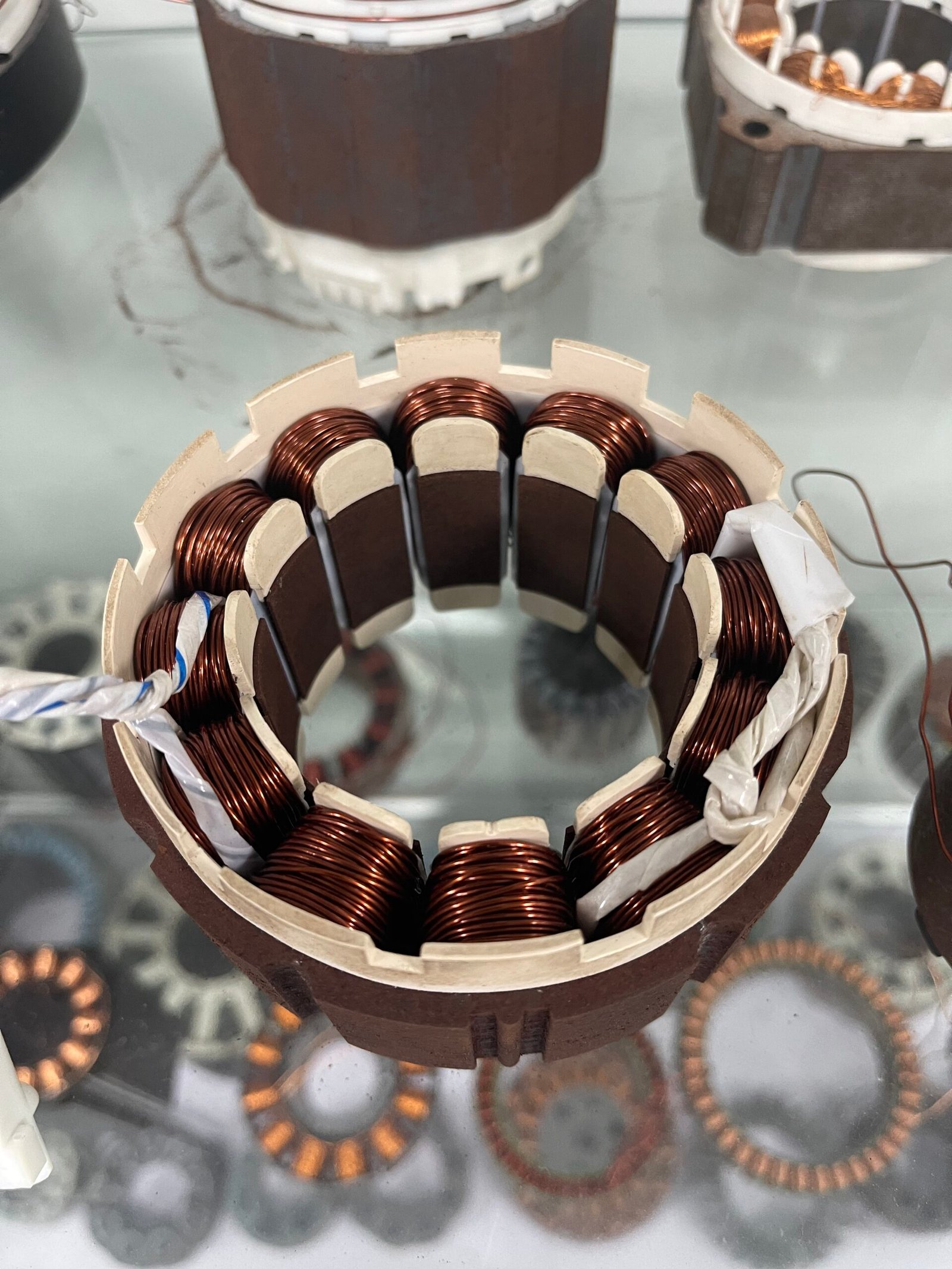

Stator Winding Machine:

Brushless Motor (BLDC): Requires support for switching between distributed and concentrated winding. For example, a needle-type internal winding machine uses modular needles to achieve “multi-purpose” functionality.

Flat Motor Stator: Utilizes laser-guided wire routing technology to address wire density issues for ultra-thin slots (height <5mm).

Rotor Winding Machine:

High-Speed Motor Rotor: Skew winding technology combined with carbon fiber fixtures minimizes coil displacement caused by centrifugal force to within 0.1mm.

Asynchronous Motor Rotor: Double-flying-fork winding machines support “winding-while-welding,” enabling integrated winding and end ring welding, improving efficiency by 40%.

3. Typical Application Scenarios

Stator Winding Machine:

New Energy Vehicle Drive Motor: Requires insulation requirements under the 800V high-voltage platform, utilizing corona-resistant enameled wire and vacuum impregnation.

Robotic joint motors: A six-station stator winding machine enables simultaneous winding of multiple slots (e.g., 24 slots), shortening production cycles.

Rotor winding machines:

Aviation starter rotors: Utilizing titanium alloy fixtures and a low-temperature winding process, they can withstand extreme environments ranging from -50°C to 200°C.

Household appliance rotors: For example, air conditioner compressor rotors, an automatic indexing system ensures a winding error of less than 2% per slot, reducing noise and vibration.

What are the similarities and differences between fully automatic stator winding machines and rotor winding machines? Vacuz has provided a brief explanation above. We hope this information is helpful!

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]