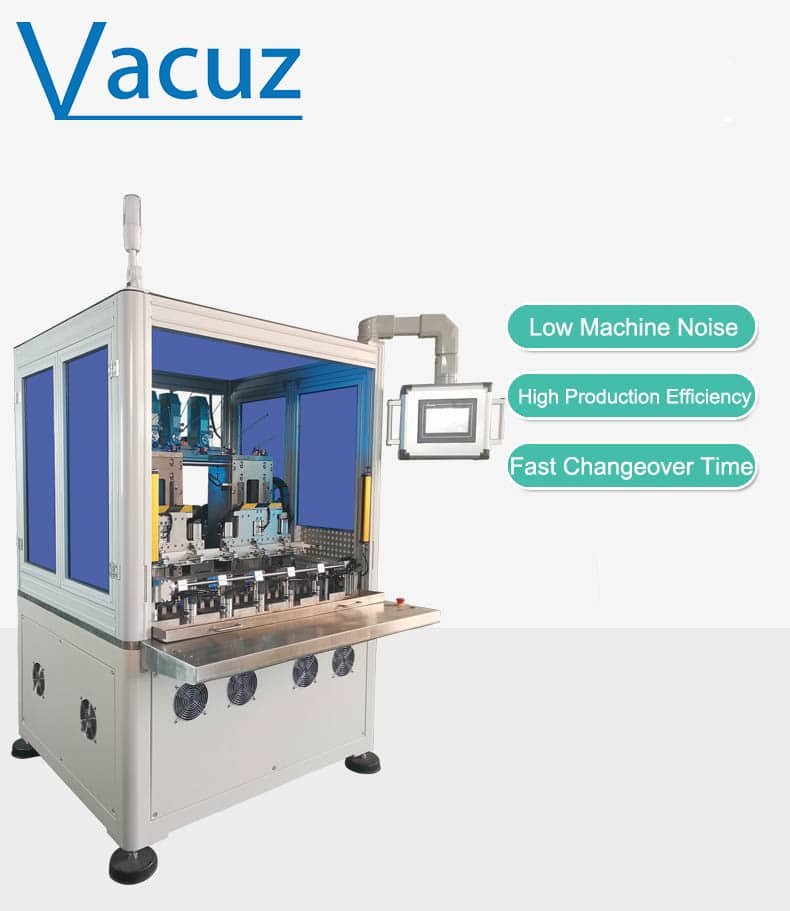

In the motor manufacturing industry, fully automatic high-speed stator winding machines have become critical equipment for improving production efficiency. However, faster production speeds aren’t necessarily better; rather, a balance must be struck between efficiency, quality, equipment lifespan, and safety. Below is a comprehensive analysis from Vacuz, which we hope will be helpful!

I. Speed Requirements for Fully Automatic High-Speed Stator Winding Machines

1. Basic Speed Range

Economical Equipment: Speeds typically range from 1000-3000 revolutions per minute (RPM), making them suitable for small-batch production or simple winding needs, such as for small household appliance motors. This type of equipment offers lower costs but limited production efficiency.

Mid-range Equipment: Speeds can reach 3000-6000 RPM, supporting multiple stations (such as four or six stations), making them suitable for small- to medium-scale production, such as power tool motors. Mid-range equipment offers a good compromise between efficiency and cost.

High-end equipment: Speeds can exceed 6,000 RPM, even reaching over 10,000 RPM. Equipped with high-precision control systems and automated mold changing, it’s suitable for large-scale production, such as for new energy vehicle motors. While high-end equipment requires a larger initial investment, it can significantly reduce unit costs in the long term.

2. Key Speed Indicators

Winding Cycle Time: The time required to complete a stator winding (including winding, mold changing, and testing). High-end equipment can reduce winding cycle time to 5-10 seconds per winding by optimizing processes and utilizing advanced technologies.

Acceleration and Deceleration: High-speed equipment must be able to start and stop quickly to reduce non-productive time (such as mold changes and wire adjustment). Fast acceleration and deceleration can significantly improve overall production efficiency.

Synchronization: Multi-station equipment must ensure that each station operates in sync to avoid uneven winding or wire breakage due to speed differences. Synchronization is a key factor in ensuring winding quality.

2. Is faster production speed always better?

1. Winding Quality and Stability

High-Speed Risks: As speed increases, controlling wire tension becomes more difficult, potentially leading to loose coils, short circuits between turns, or insulation damage. Furthermore, wire routing accuracy decreases, resulting in problems such as wire jumps and overlaps, impacting motor performance (e.g., efficiency and noise).

Solution: Implement a closed-loop tension control system to adjust tension in real time to accommodate speed changes. Equip with high-precision visual inspection or laser positioning systems to ensure accurate wire routing.

2. Equipment Lifespan and Maintenance Costs

High-Speed Wear: Mechanical components (e.g., bearings and gears) are susceptible to wear at high speeds, requiring more frequent replacement. Electrical components (e.g., servo motors and drives) may overheat due to frequent starting and stopping, shortening their lifespan.

Cost Comparison: High-speed equipment requires a higher initial investment, and maintenance costs (e.g., spare parts and labor) can increase by 30%-50%. In contrast, low-speed equipment, while less efficient, simplifies maintenance and is suitable for small-scale or customized production.

3. Process Compatibility

Wire Diameter and Stator Size: Thin wire (<0.1mm) requires reduced speed to prevent wire breakage, while thick wire (>0.8mm) requires controlled acceleration to prevent coil deformation. Large stators (such as industrial motors) have high inertia, so high-speed winding can lead to chaotic winding, requiring optimization of the oscillating needle mechanism.

Winding Method: Multi-wire winding requires synchronized control of multiple wires, which can easily lead to uneven tension at high speeds, requiring an independent tension control system.

4. Safety and Operational Risks

High-speed Risks: Mechanical components (such as flying forks and winding nozzles) can become dislodged due to centrifugal force at high speeds, posing a safety hazard. Operators require more rigorous training to handle the high-risk operations of high-speed equipment (such as emergency shutdowns and troubleshooting).

Safety Design: High-end equipment is often equipped with safety light curtains, emergency stop buttons, and fault self-diagnosis systems to reduce accident rates. These safety features are crucial for ensuring operator safety.

III. Selection Recommendations: How to Balance Speed and Requirements?

1. Clearly Define Production Goals

Large-Scale Production: Prioritize high-speed equipment (e.g., 6000 RPM and above) to reduce unit costs through automation. High-speed equipment can significantly improve production efficiency and meet the needs of large-scale production.

Small-Batch/Customized Production: Select medium- to low-speed equipment (e.g., 3000-5000 RPM), balancing flexibility and cost. Medium- to low-speed equipment can meet the needs of small-batch or customized production while maintaining good cost-effectiveness.

2. Evaluate Process Constraints

If the wire diameter is thin or the stator size is large, the speed may need to be reduced to ensure quality. For example, a model aircraft motor manufacturer, with a wire diameter of only 0.08mm, selected a 4000 RPM machine equipped with precision tension control to ensure winding quality.

Given the complexity of the winding method, parallel winding of multiple wires requires independent tension control systems to address uneven tension at high speeds.

3. Consider Long-Term Costs

While high-speed equipment offers high efficiency, maintenance costs, spare parts inventory, and operator training must be considered.

When selecting equipment, you should consider initial investment, operating costs, and maintenance costs to find the most cost-effective solution.

We hope this information is helpful. If you have other needs or questions, such as a more detailed analysis of a specific type of fully automatic high-speed stator winding machine or more case studies on equipment selection, please feel free to let Vacuz know.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]