Winding the outer rotor of a brushless motor is a relatively important process. In addition to automatic winding, automatic loading and unloading is also a popular trend now. So what are the advantages and characteristics of automatic winding loading and unloading equipment for brushless motor outer rotors? Vacuz will introduce it to you!

1. Significant advantages

1. Revolutionary improvement in production efficiency :

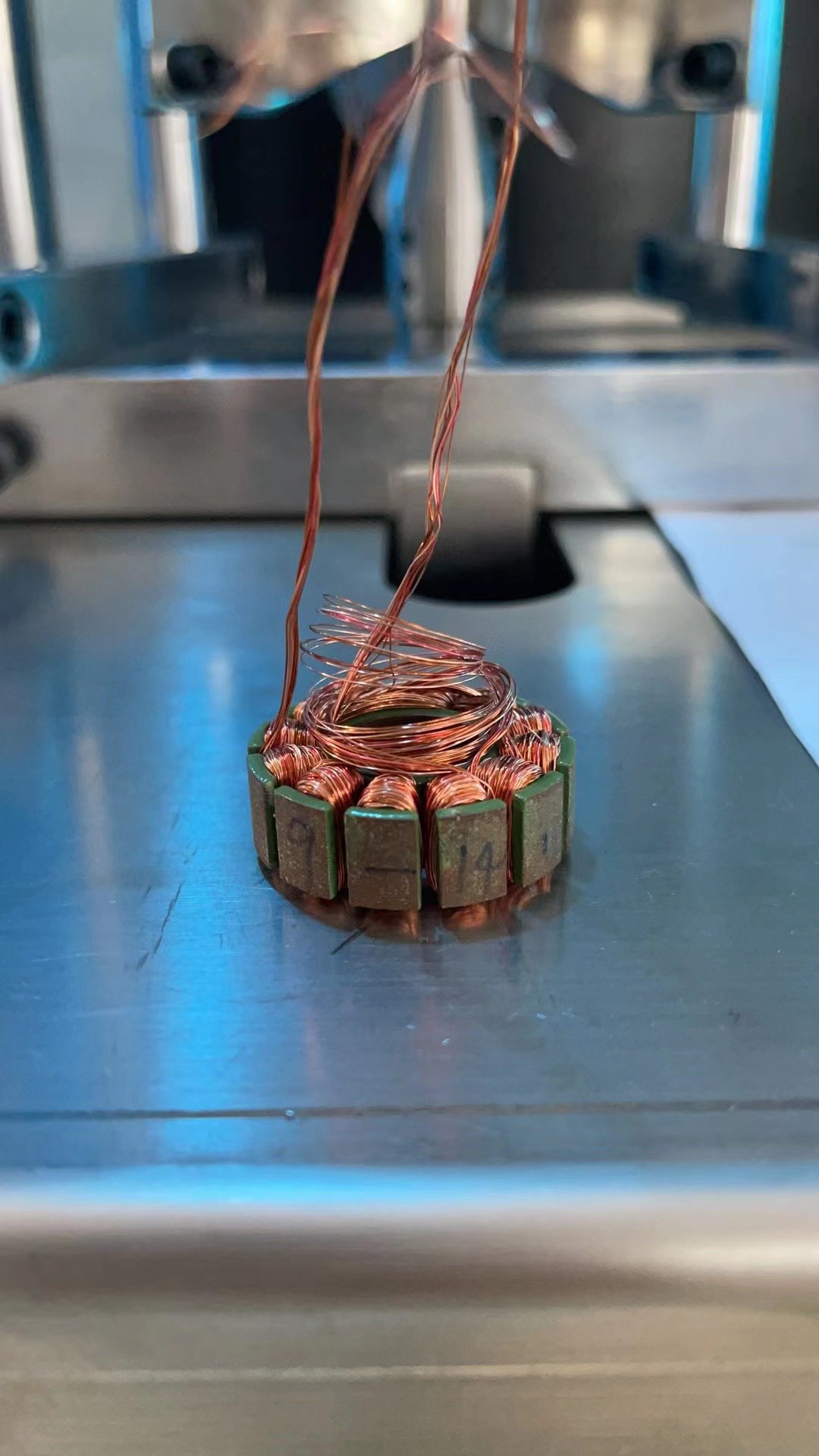

The entire line of the equipment adopts intelligent control, and each process is seamlessly connected. The design is ingenious, realizing one-stop completion from automatic loading and unloading, automatic clamping, automatic winding, wiring to clamping and shearing. This innovative model shortens the production cycle and achieves a qualitative leap in production efficiency.

Compared with traditional manual semi-automatic equipment, the fully intelligent production mode greatly reduces manual intervention. Only one person can easily cope with the workload that used to require more than ten people to complete. The improvement in production efficiency is obvious.

2. Excellent guarantee of product consistency :

The built-in servo control system and PLC controller of the equipment can accurately control the key parameters such as the start and stop, forward and reverse rotation, speed, number of turns, time, etc. of the winding to ensure the accuracy and high stability of the winding process.

The wiring is compact and orderly, neat and uniform, and the precision wiring effect can be easily achieved, thus ensuring the consistency of the product and the high level of yield rate.

3. Easy operation and flexible debugging:

The equipment is equipped with an intuitive human-machine interface, the operation is intuitive and easy to understand, the debugging process is easy and convenient, and the workshop staff can quickly get started after a brief training.

The parameter setting is free and flexible, and a variety of winding process schemes can be preset, which is convenient to call at any time, and the adjustment of the winding process becomes arbitrary.

4. Low noise, improved comfort of the working environment:

The equipment runs smoothly and the noise is extremely low. Even if multiple devices are running at the same time, no disturbing noise will be generated, creating a more comfortable and quiet working environment for the staff.

5. Non-standard customization, strong adaptability:

The equipment supports non-standard customization services. For special products or special-shaped products that exceed the conventional outer diameter and wire diameter, a tailor-made mode can be adopted to accurately solve various winding problems.

The modular design gives the equipment a high degree of flexibility and ductility, supports rapid mold change of multiple models of products, and meets diversified production needs.

II. Outstanding features

1. High accuracy and extraordinary stability:

The equipment uses high-quality parts such as precision guide rails, screw rods, cylinders, tensioners, etc. to ensure smooth and unimpeded operation of the machine, and the tightness of the wire is just right, avoiding the phenomenon of wire damage and derailment.

The overall frame adopts a sturdy structure of sheet metal and aluminum profiles, with excellent shock absorption performance and strong stability, and can maintain small vibration even at high speed.

2. The pinnacle of intelligence and automation level:

The equipment integrates advanced PLC controllers and servo drive systems, with rigorous logical operation relationships, impeccable stability and safety, and truly realizes unmanned automatic production lines.

The equipment has intelligent functions such as fault diagnosis and production storage, which can automatically identify the processing status of the workpiece, effectively reducing downtime and maintenance time, and improving the overall efficiency of the production line.

3. Perfect combination of multi-station and efficient production:

The equipment is flexibly set to 1/2/4/6 stations according to the different parameters of the brushless motor stator such as the number of slots, wire diameter, outer diameter, etc., and the appropriate winding equipment is used for different products, and the production efficiency is further optimized.

Multi-station simultaneous winding processing, adjustable and controllable speed, meet the needs of large-scale production, and provide strong support for the company’s capacity expansion.

4. Modular design and convenience of rapid changeover:

The equipment adopts a modular design concept, the fixture is modularly set, the position is fixed and the positioning is accurate, and the disassembly and replacement process is simple and fast. This design makes it possible to quickly change molds for multiple models of products, greatly improving the flexibility and efficiency of production.

What are the advantages and characteristics of automatic winding loading and unloading equipment for brushless motor outer rotors? Vacuz has made a brief explanation above, and I hope this knowledge can help everyone!

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]