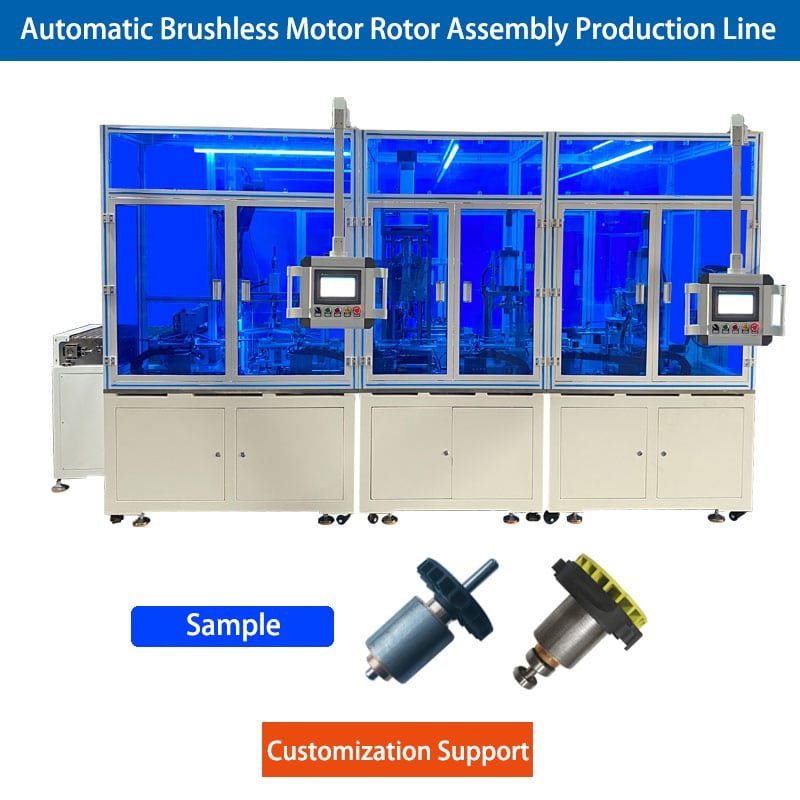

In today’s highly efficient and accurate manufacturing environment, the assembly of brushless motor rotor production lines demonstrates significant advantages that not only drive leaps in production efficiency, but also ensure a steady improvement in product quality. What are the advantages of brushless motor rotor production line assembly? How to design the line body more practical, Vacuz give you an introduction!

I. Overview of the advantages of assembly

1. Efficient production, speed is king:

Brushless motor rotor automatic production line through the integration of advanced automation equipment and processes, significantly shorten the production cycle, reduce the manual operation time, to achieve a significant increase in production efficiency. This high-efficiency production mode has won the first opportunity for enterprises to compete in the market.

2. Stable quality and accurate control:

Automated equipment and processes effectively circumvent unstable factors in manual operation, such as environmental interference and emotional fluctuations, thus ensuring the stability and consistency of product quality. Accurate positioning, installation, adjustment and inspection links further enhance the accuracy and fineness of the products.

3. Cost reduction and benefit enhancement:

Automated production reduces the reliance on labor and lowers labor costs. At the same time, through the optimization of equipment and processes, it reduces material waste and the rate of defective products, realizes further reduction of production costs, and brings higher economic benefits for the enterprise.

4. Flexible and adaptable:

Brushless motor rotor automatic production line has a high degree of flexibility and can quickly adapt to the production needs of different products and batches. By adjusting the equipment and process parameters, the enterprise can easily switch to produce rotors of different specifications and models to meet the diversified needs of the market.

Second, the design of practical production line recommendations

1. Modular design, easy to maintain and upgrade:

The production line is divided into a number of independent modules, each module to undertake specific production tasks. This modular design is not only convenient for maintenance and upgrading, but also can flexibly adjust the number of modules and layout according to the production demand, improve the adaptability and flexibility of the production line.

2. Enhance the degree of automation and realize intelligent production:

Introduce advanced automation equipment and robotics to realize the processes of automatic feeding, automatic winding, automatic assembly and automatic inspection of rotors. Combined with big data analysis and high-accuracy testing technology, it realizes accurate production and quality control, and improves the intelligent level of the production line.

3. Intelligent management to optimize the production process:

Establish an intelligent management system for real-time monitoring and scheduling of the production line. Through data analysis, bottlenecks and problems in the production process can be found, and the production process can be optimized in time to improve production efficiency and quality. At the same time, the intelligent management system can also provide strong support for enterprise decision-making.

4. Humanized operation, reduce operation difficulty:

Design simple and clear operation interface and humanized operation process to reduce operation difficulty and complexity. Provide perfect training and guidance services to ensure that operators can quickly master the operating skills and improve the overall operating efficiency of the production line.

5. Focus on environmental protection and energy saving, and realize sustainable development:

In the production line design process, focus on the application of environmental protection and energy saving concepts. Choose equipment and materials with low energy consumption and low emission, reduce energy consumption and environmental pollution by optimizing the structure and adjusting the process, etc., and realize the sustainable development goal of the enterprise.

To sum up, the assembly advantages of brushless motor rotor production line are remarkable, while the design of a more practical production line needs to start from a number of aspects such as modularization, automation, intelligence, humanization and environmental protection and energy saving. Only in this way can we continue to promote the progress and development of the manufacturing industry and create greater value for the enterprise.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]