With the rapid development of the motor industry, the demand for motor winding machines is also increasing, whether in terms of speed, or output, or in terms of quality, the winding machine has put forward higher demand. As a professional winding machine equipment, in addition to quality performance, its winding method is also very important, then the common brushless motor winding machine, which are several winding methods?

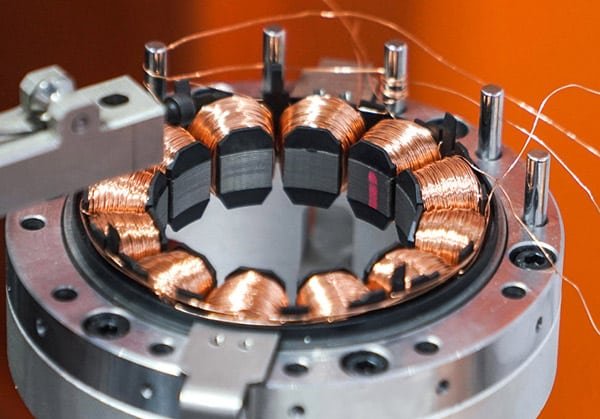

1. Flying fork winding, this winding method is often used for motor stator with outward slot, such as model motor, balance car motor, scooter motor, new energy car motor, resolver, fan stator, twist car motor, cooling fan stator, plant protection machine, all kinds of external winding stator, etc. After the parameters are set, the copper wire is driven by the high speed rotation of the flying fork, and the guard plate plays an auxiliary role, which is stuck into the slot of the copper wire, and through the back and forth movement of the die, the wire is arranged in an orderly manner, making each slot arranged in a precise manner.

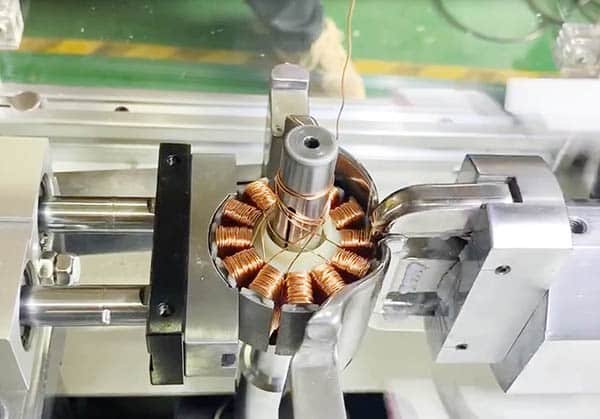

2. Needle winding, this winding method is often used in the slot inward motor stator, such as power tools, pumps, stepper motors, vacuum cleaner motors, road gates, winches, etc. After the parameters are set, the tungsten steel wire nozzle moves with the wire, and through the up-and-down and back-and-forth movement of the guide pin, precision wire arrangement and winding work is achieved.

Both winding methods have their own advantages, both have their own applicable range, both have universal models, also can be non-standard customized, price wise, the external winding will be relatively cheaper, the internal winding is more expensive. What kind of samples with what kind of machine, basically a glance to know, according to their own needs of production, the choice of different stations of winding machine equipment.

These are the two common winding methods of brushless motor winding machine, master the basic principles of these winding methods to ensure a reasonable design of the stator winding, so that the line can be wound better and more precise.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]