No matter DC motor or AC motor, the motor has rotor and stator, which are inseparable and complement each other. Stator is the static part of the motor, for AC motor, it mainly consists of stator core, main shaft winding and frame; for DC motor, the stator mainly includes main magnetic pole, commutation pole, frame and brush and other parts.

Brushless DC Motor

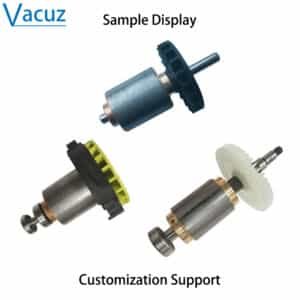

Motor rotor is the part of the motor that can be rotated. The rotor of AC motor is composed of iron core, rotor winding and rotor shaft; the rotor of DC motor is mainly composed of armature iron core, armature winding and commutator.

For AC motor, no matter how big the power is, its main shaft core is generally made of 0.35mm~0.5mm thick silicon steel punching sheet, and the surface of silicon steel sheet is coated with insulating paint. The main purpose is to reduce the loss of the spindle core, such as reducing eddy current loss, improve the efficiency of the motor. As we know, whether it is the spindle or rotor of the motor, they are part of the magnetic circuit of the motor, especially in AC motors, when the alternating magnetic field passes through the spindle and rotor, heat will be generated, and due to eddy current effect, it will not only make the motor heat up seriously, but also reduce the efficiency of the motor.

For large and medium-sized DC motors, the main pole cores are made of silicon steel sheets or thin iron sheets riveted with a thickness of 0.5mm to 1.5mm, also to reduce eddy currents, due to the fast change of current. However, we will find that in small DC motors, its stator sometimes uses a whole piece of cast iron as the pole. This is because the commutation pole is part of the DC motor spindle, which has a relatively large air gap with the rotor, so the eddy current loss is not significant, and it is machined from a single block of steel because it is relatively simple to make.

Brushless motor rotor production line

We usually observe and see that not only the spindle and rotor cores of motors are made from silicon steel sheets one by one, but in larger inductive loads, the cores they use generally need to be used one by one. Metal parts, such as the iron cores in power transformers and in AC contactors, are not a single core when we take them apart, but are made of silicon steel sheets. The main purpose of this is to reduce eddy current losses and improve their efficiency, as well as to reduce the heat generated during operation so as not to cause serious heating.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com