Rotor and stator are both components of the motor, now assembly most of the special automated production line, according to different products, can be semi-automated or fully automated production equipment, then what is the difference between the rotor and stator assembly line? How to improve the degree of automation, Vacuz give you an introduction to it!

The difference between rotor and stator assembly line:

1. Product characteristics and requirements:

Stator: As the fixed part of the motor, its core lies in the winding, which is used to generate the magnetic field. It has a large number of winding lines and small winding angle, which has high requirements on winding precision and insulation treatment.

Rotor: As the rotating part of the motor, its structure includes iron core, rotating shaft and bearings. The number of rotor wires is relatively small, the winding angle is large, and it is necessary to ensure the stability and durability of the rotating process, so it pays more attention to the processes of bearing installation and dynamic balance correction.

2. Production line configuration and process:

Stator production line: focusing on the fine operation of the winding process, to ensure the quality of the winding and insulation effect, in order to achieve the purpose of generating a stable magnetic field.

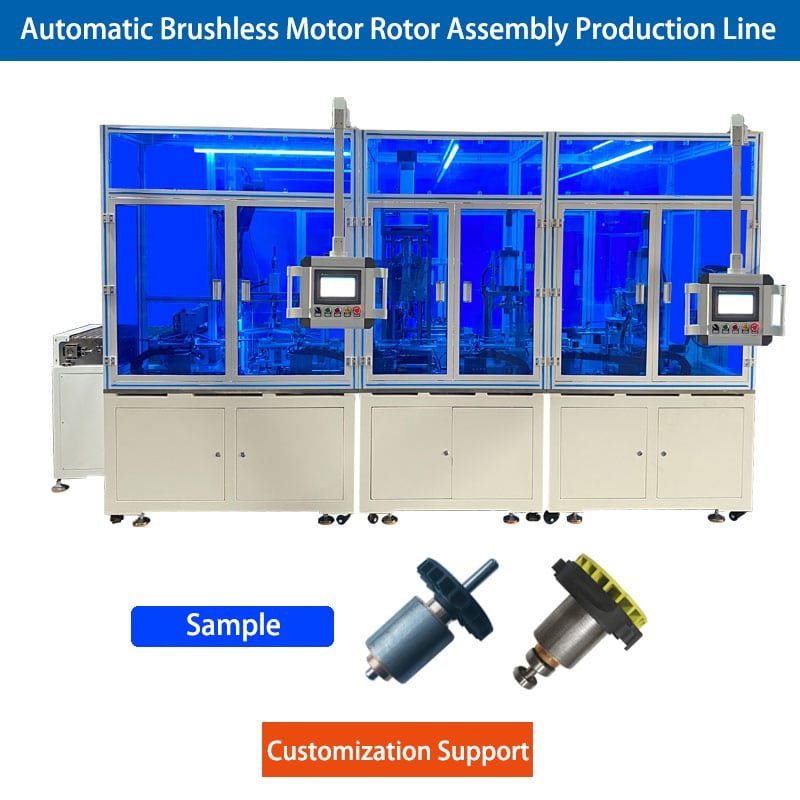

Rotor production line: more emphasis on the accurate installation of bearings, dynamic balance adjustment, etc., in order to ensure the smoothness and durability of the rotor in high-speed rotation.

3. Automation and intelligence level:

Although there are differences between the two in terms of automation and intelligence needs, but the common trend is to use high-accuracy, automated equipment and systems to improve production efficiency and product quality.

Strategies to increase the level of automation:

1. Adopt high-accuracy, automated assembly equipment: such as robotic assembly systems and automated assembly machines to reduce human error and improve assembly precision and efficiency.

2. Implement intelligent control system: integrate ERP, MES and other systems, real-time monitoring of production data, optimize resource allocation and production process.

3. Apply high-accuracy visual inspection system: Ensure the correct installation of parts in the assembly process, and improve product quality control level.

4. Optimize production line layout and station design: adopt parallel production mode, reasonably arrange station and equipment layout, and improve production efficiency. At the same time, formulate standardized operation norms to reduce human error.

5. Strengthen staff skill training and incentive mechanism: improve staff skill level, encourage staff to participate in the improvement and innovation of the production line, and form a cultural atmosphere of continuous improvement.

6. Implement equipment maintenance and repair programs: ensure that the equipment is in good condition, prevent potential failures, and guarantee the continuous and stable operation of the production line.

To summarize, by implementing the above strategies, we can effectively improve the automation degree of rotor and stator assembly line, and further improve the production efficiency and product quality.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]