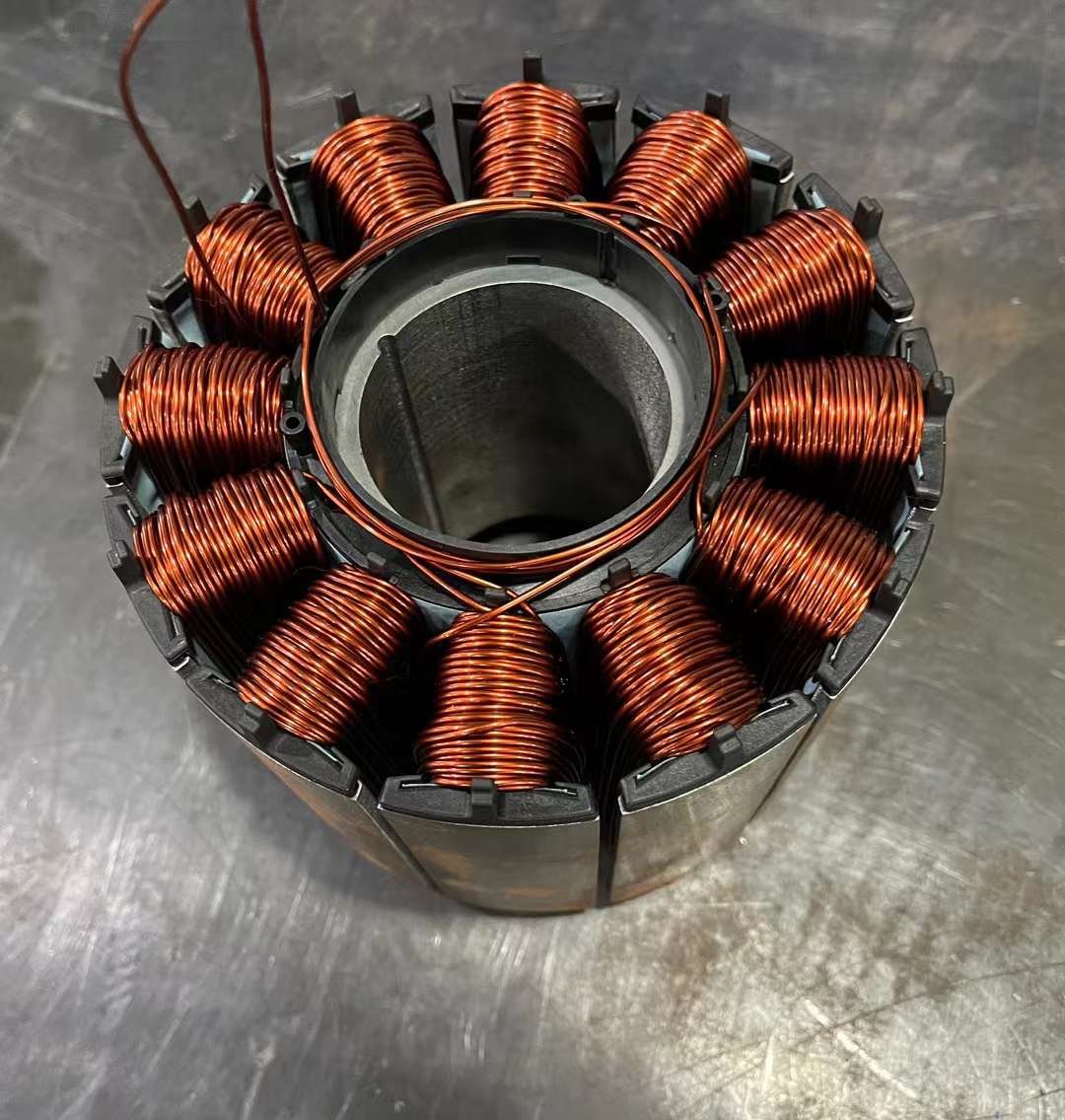

Brushless motor stator winding there are two common ways, according to the direction of the stator slot opening, can be divided into the inner winding and outer winding, different winding methods, the winding process also makes a difference, general common single-wire winding mostly, but if it is a multi-wire inner winding and outer winding, what is the difference between the two? What details need to pay attention to Vacuz to analyze!

1. Stator winding, generally using specialized internal winding machine equipment, that is, the common needle winding method, multi-wire winding is more difficult, the common internal winding machine can support double, triple, quadruple, multi-wire, etc., multi-wire internal winding wire diameter can not be too thick, generally 0.5mm or less, more than 0.5mm will be difficult, not only is it easy to hurt the line breakage, and the slot is small, then, but also can not be wound into. So do a good job of assessing the configuration and stability of the internal winding machine should also be over the top, pay attention to debugging the machine, molds and wire devices should meet the requirements.

2. Stator external winding, generally using specialized external winding machine equipment, that is, the common flying fork winding method, the external winding of multiple lines and winding is more common, such as robots, planting machines, scooters and other brushless motors stator, 0.3mm or less, can be more than 30 lines together and winding, the difficulty is not very large, but the distance between the grooves are also wider, the line should be able to go around it, pay attention to winding, to avoid injury to the line, broken lines, stacked lines, etc., to avoid the injury to the line, the line should be broken, the line should be stacked. The configuration of the machine as well as the stator parameters should meet the requirements.

As can be seen from the above, multi-wire winding and multi-wire winding, in addition to the winding method is not the same, multi-wire winding is more difficult, for the configuration of the machine requirements are also higher, winding requirements are also more stringent, in the winding, should also pay attention to the injury line, line breakage and other issues, to ensure that the winding meets the requirements!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]