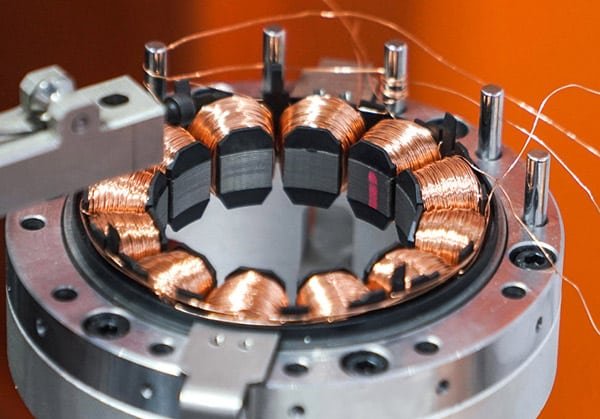

Sometimes, in the commissioning of motor stator winding machine, the beginning of the winding well, but suddenly produce broken wire phenomenon, which is caused by what is it?Vacuz briefly give you an analysis of.

1. May be a problem with the placement of the barrel, may also be stuck in the line, pay attention to check the barrel has no defects.

2. Motor stator winding machine tensioner settings have problems, the tension is set too large, easy to cause broken wire, there are generally tension table can be checked against.

3. Winding mold and line mouth corresponding to the problem, may also cause broken line problem.

4 motor stator winding machine program parameters set improperly, winding speed is too fast, no start slow winding, etc. will cause broken wire.

5. It is also possible that the middle guard plate is not well positioned, and the lower line is scraped to the steel sheet.

6. motor stator winding machine winding line mechanism is not precise enough, workmanship is poor, may also lead to deviations produce broken wire problem.

These are the causes of wire breakage when winding motor stator winding machine, mastering these basic knowledge, in order to better use the winding machine, in order to make the winding work more smoothly.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]