Coil winding machine principle_Coil winding machine adjustment_I. Spiral wire winding process

1. Spiral wire winding specifications

Before we introduce what is the principle of spiral coil winding machine people winding process, the first spiral wire winding specifications, because the winding specifications directly determine the coil winding machine winding mode.

The winding mode of high precision winding machine is single-layer one-way continuous spiral, and the winding mode is divided into four main types, i.e. equal-pitch winding, gradual-pitch winding, jump-pitch winding and mixed-pitch winding.

Equal pitch: i.e. the pitch of each turn is equal.

Gradual pitch: There are two main types, one is equal pitch and the other is equal ratio pitch.

Jump pitch: first winding with one pitch, then change to another pitch.

Mixed pitch: first winding with one pitch evenly, then winding with gradual change of pitch; or group fire of the above modes

The winding material is mostly tungsten or Leitungsten alloy in annealed condition. The figure below shows a diagram of a wound spiral wire. The shape and structure of the spiral wire is roughly illustrated.

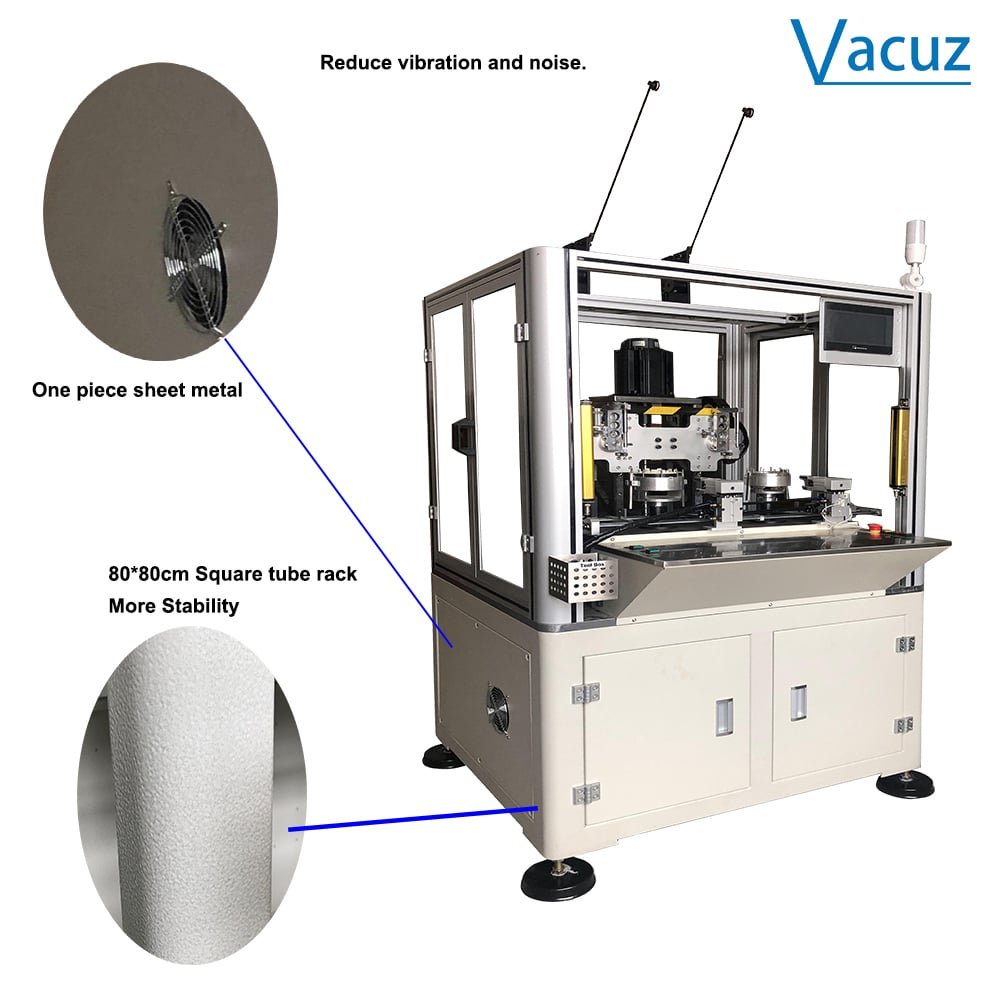

Coil winding machine factory

2. Winding process

The coil winding machine is to wind single spiral coils with the corresponding pitch size according to the customer’s process requirements. Since the bandwidth B error of the high purity tungsten tape or aluminum tape itself is in the micron level, the pitch A error of the winding needs to be within a permissible micron level error band to meet the product requirements.

Therefore, to wind this kind of spiral coil will put forward more demanding requirements for the structure of the winding machine, mainly in the following aspects, one requires a reasonable structure of the winding machine, the second as a high-precision equipment corresponding winding machine tolerance fit should be good, the third, is the choice of the corresponding structural materials, part of the structure needs to be used for the characteristics of the special process to meet the requirements. This will ensure that the control system in the work so that its mechanical transmission caused by the vibration may be small, that is, smooth and fast.

Before introducing the winding machine, a general introduction to the winding process of the winding machine structure winding spiral wire, the winding machine structure, that is, for a two-headed clamping, the middle of the horizontal movement of the winding machine mechanism through the screw drive row of wire mechanism. The winding requires a good clamping of the core rod, and does not allow the core rod and the clamping mechanism to slide relative to each other, then the strip material is wound on the core rod several times in advance and fixed. The single spiral coil is wound.

The fixed base is generally fixed to the base of the winding machine through the positioning pins and cannot be moved, while the tailstock is generally a horizontally movable mechanism mounted on parallel rails to help realize the clamping of core rods of different lengths. And in the motor drive synchronous start and stop, constant speed rotational movement, the difference is that the two rotational direction opposite.

WhatsApp/Wechat:+86 13075286997

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]